Temperature-resistant and salt-resistant multi-component copolymerization pre-crosslinked gel particle and preparation method and application thereof

A multi-component copolymerization, temperature-resistant and salt-resistant technology, which is applied in the fields of petroleum exploration, transportation and chemical industry, can solve the problem of unstable structure of pre-crosslinked gel particle crosslinking agent, high molecular chain content and low molecular weight, and difficult to meet the requirement of oil reservoir sweep Volume and other issues, to achieve effective control of the reaction rate, high molecular weight, and the effect of chain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

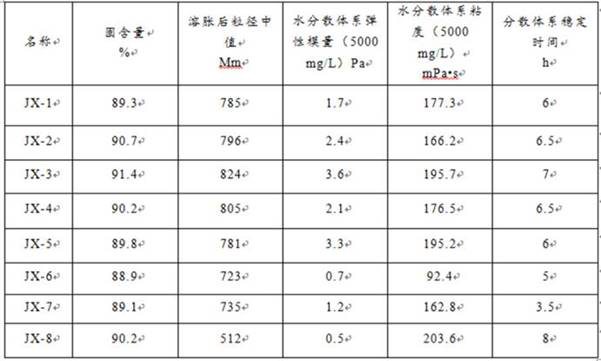

Examples

Embodiment 1

[0054] Add 100Kg deionized water into the reaction kettle, then add 15Kg AM and 1Kg AMPS in sequence, and then add the next substance after the previous substance is completely dissolved, while keeping the temperature of the reaction system at 25°C, stir for 1 hour, and finally fully stir and mix. uniform. Add 2.32Kg of N,N-dimethylacrylamide to the above reaction system, and after it is fully dissolved and mixed well, inject nitrogen gas into the reaction solution for 30 minutes through the nitrogen port at the bottom of the reaction kettle, so as to fully remove the oxygen in the reaction system. Adjust the pH in the reaction kettle, and slowly add 0.1015Kg potassium persulfate and 0.0145Kg 1-acetate-3-allylimidazolium tetrafluoroborate composite initiation system aqueous solution prepolymerization into the reaction system under the protection of nitrogen.

[0055] The reaction kettle was sealed, and 2.32Kg of nanoclay was added during the process. The reaction time was 3 ho...

Embodiment 2

[0058] Add 100Kg deionized water into the reaction kettle, then add 15Kg AM and 5Kg AMPS in sequence, and then add the next substance after the previous substance is completely dissolved, while keeping the temperature of the reaction system at 30°C, stir for 1 hour, and finally fully stir and mix. uniform. Add 3.12Kg of N,N-dimethylacrylamide to the above reaction system, and after it is fully dissolved and mixed well, inject nitrogen gas into the reaction solution for 30 minutes through the nitrogen port at the bottom of the reaction kettle, so as to fully remove the oxygen in the reaction system. Adjust the pH in the reaction kettle, slowly add 0.54Kg potassium persulfate and 0.06Kg 1-acetate ethyl-3-allylimidazole bis(trifluoromethanesulfonyl)imide salt to the reaction system under the protection of nitrogen Initiate the prepolymerization of the aqueous solution of the system.

[0059] The reaction kettle was sealed, and 2.6Kg of nanoclay was added during the process. The ...

Embodiment 3

[0062] Add 100Kg deionized water into the reaction kettle, then add 50Kg AM and 1Kg AMPS in turn, and then add the next substance after the previous substance is completely dissolved, while keeping the temperature of the reaction system at 27°C, stir for 1 hour, and finally fully stir and mix. uniform. Add 1.609Kg N,N-dimethylacrylamide to the above reaction system, and after it is fully dissolved and mixed well, inject nitrogen gas into the reaction solution for 30 minutes through the nitrogen port at the bottom of the reaction kettle, so as to fully remove the oxygen in the reaction system. Adjust the pH in the reactor, and slowly add 0.4027Kg of potassium persulfate and 0.0503Kg of 1-acetate-3-allylimidazole hexafluorophosphate to the reaction system under the protection of nitrogen to initiate the pre-polymerization of the aqueous solution of the system.

[0063] The reaction kettle was sealed, and 3.322Kg of nanoclay was added during the process. The reaction time was 3.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com