Composite aluminium, cerium and zirconium oxide catalytic material and method for producing same

A composite oxide and catalytic material technology, applied in the field of aluminum-cerium-zirconium composite oxide catalytic material and its preparation, can solve the problem of affecting the catalytic activity and high-temperature thermal stability of the oxygen storage material, affecting the uniformity of the coating layer and the coating layer. Problems such as carrier adhesion, poor high temperature aging resistance of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of aluminum cerium zirconium composite oxide catalytic material of the present invention, it comprises the steps:

[0055] (1) Preparation of active component slurry: According to the composition of the material, dissolve the corresponding cerium nitrate, soluble salts of other rare earths except cerium and zirconium nitrate in water to obtain a mixed metal nitrate solution; in the mixed metal nitrate solution Adding activated alumina and structure directing agent, shearing and dispersing, to obtain active component slurry A;

[0056] (2) Precipitation: At a certain temperature, add ammonia water to the above-mentioned active component slurry A until the end of the precipitation, add Ce 3+ Oxidized to Ce 4+ The required stoichiometric hydrogen peroxide is kept for a certain period of time to obtain sediment B;

[0057] (3) Surface treatment of the sediment, dehydrating and washing the sediment B; repulping the dehydrated sediment B and water at ...

Embodiment 1

[0070] Dissolve 64.9kg of cerium nitrate, 29.8kg of zirconium nitrate, and 13.5kg of lanthanum nitrate in 500kg of pure water, and add 60kg of γ-Al with a pore volume of 0.31g / ml 2 o 3 , 16kg of ammonium citrate, shear dispersion; after heating the above slurry to 60°C, slowly add ammonia water, control the pH at the end point to 9, add 11.8kg of 30% hydrogen peroxide, and keep warm for 4h. After the sediment was centrifuged and dehydrated, it was mixed with water at a mass ratio of 2:1, and 32.5 kg of diethylene glycol monobutyl ether (C8H18O3) was added to shear and disperse. The dispersed turbid liquid was calcined at 550° C. for 6 hours to obtain the aluminum cerium zirconium composite oxide catalytic material.

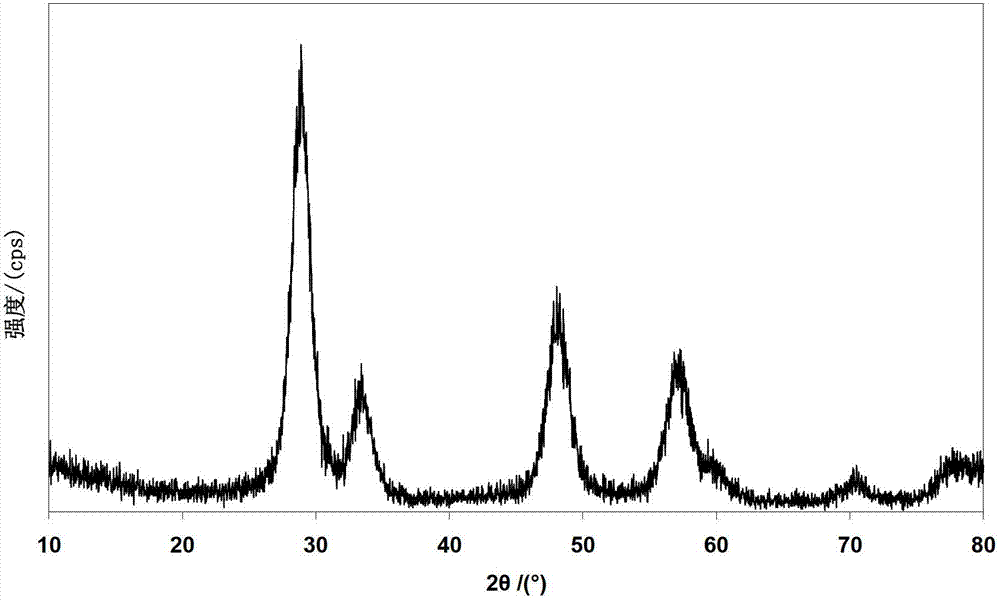

[0071] The composition of the material is 24% of cerium oxide, 11% of zirconia, 5% of lanthanum oxide, and 60% of aluminum oxide. The material has a fresh specific surface area of 140m 2 / g, the specific surface area obtained after calcination of the material...

Embodiment 2

[0073] Dissolve 64.9kg of cerium nitrate, 29.8kg of zirconium nitrate, and 13.5kg of lanthanum nitrate in 500kg of pure water, and add 60kg of γ-Al with a pore volume of 0.68g / ml 2 o 3 , 16kg of ammonium citrate, shear dispersion; after heating the above slurry to 60°C, slowly add ammonia water, control the pH at the end point to 9, add 11.8kg of 30% hydrogen peroxide, and keep warm for 1h. After centrifugation and dehydration of the precipitate, it is mixed with water according to the mass ratio of 2:1, and 54.1kg of ethylene glycol monobutyl ether (C6H14O2) is added to shear and disperse. The dispersed turbid liquid was calcined at 750° C. for 4 hours to obtain the aluminum-cerium-zirconium composite oxide catalytic material.

[0074] The composition of the material is 24% of cerium oxide, 11% of zirconia, 5% of lanthanum oxide, and 60% of aluminum oxide. The material has a fresh specific surface area of 182m 2 / g, the specific surface area obtained after calcination of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com