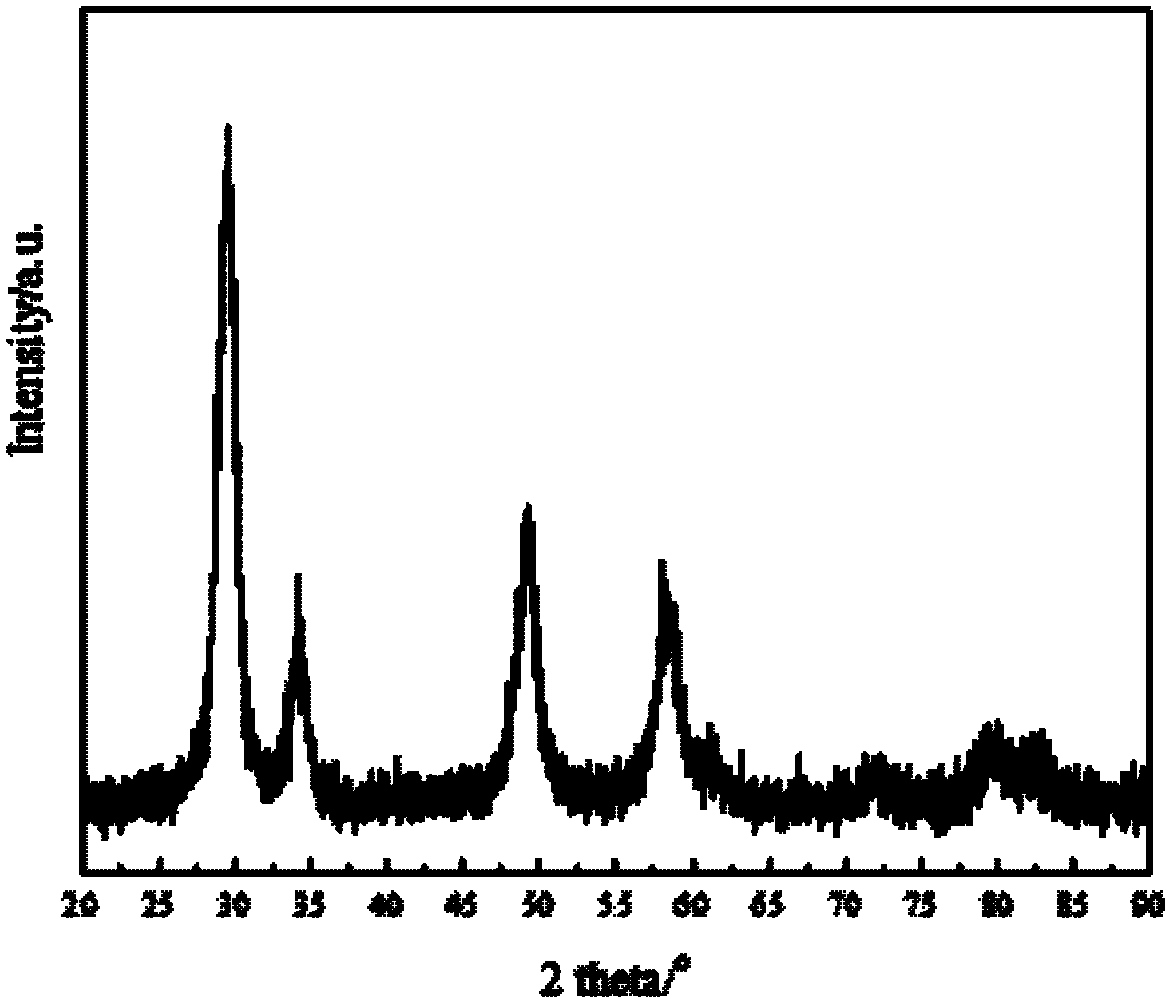

Nanometer ceria-zirconium solid solution and preparation method thereof

A cerium zirconium solid solution and nanotechnology, applied in the field of solid solution and its preparation, can solve the problems of requiring high pressure equipment, inability to mix uniformly, and not suitable for large-scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] On the other hand, the preparation method of nanometer cerium-zirconium solid solution of the present invention, it comprises the steps:

[0038] (1) Preparation of acidic solution A: dissolving zirconium carbonate with concentrated nitric acid, adding cerium nitrate and other mixed rare earth nitrates according to the composition of cerium-zirconium solid solution, dissolving, then adding structure-directing agent, and aging;

[0039] (2) Preparation of alkaline solution B: get an appropriate amount of concentrated ammonia or ammonium bicarbonate to be mixed with alkaline solution B at a concentration of 4mol / L;

[0040] (3) Precipitation reaction: add the acidic solution A into the alkaline solution B at a certain speed to generate a precipitate, add metered hydrogen peroxide, and then age for a certain period of time to obtain a solid-liquid mixed system C;

[0041] (4) Washing: dehydrating the solid-liquid mixed system C, rinsing, and filtering to obtain wet cake D;...

Embodiment 1

[0050] Dissolve 150kg of zirconium carbonate with 100Kg of nitric acid, add 76.0kg of cerium nitrate, 13.3Kg of lanthanum nitrate, and 17.0Kg of yttrium nitrate, stir and dissolve, then add 6Kg of cetyltrimethylammonium bromide, add pure Water to 500L, aged at 80°C for 4h to obtain acidic solution A.

[0051] Dilute 400Kg of ammonia water and pure water to 1200L, and keep it at 70°C for 1 hour to obtain alkaline solution B.

[0052] Under stirring, add the above-mentioned acidic solution to the alkaline solution B at a rate of 5 L / min to obtain a gray precipitated solid-liquid system, control the pH value of the end point to 9, add 14.8Kg of 30% hydrogen peroxide, and then Aging 4h. Obtain solid-liquid mixed system C. Filter, rinse with 600Kg hot water, and filter. Get wet cake D.

[0053] The wet cake D and water were repulped at a mass ratio of 2:1, 80Kg of lauric acid was added, and the slurry E was obtained by shearing and dispersing. The slurry E was calcined at 750°...

Embodiment 2

[0056] Dissolve 150kg of zirconium carbonate with 100Kg of nitric acid, add 76.0kg of cerium nitrate, 13.3Kg of lanthanum nitrate, and 13.1Kg of neodymium nitrate, stir and dissolve, then add 6Kg of cetyltrimethylammonium bromide, add pure Water to 500L. Aged at 75°C for 4h to obtain acidic solution A.

[0057] Dilute 400Kg of ammonia water and pure water to 1200L, and keep it at 70°C for 1 hour to obtain alkaline solution B.

[0058] Under stirring, add the above-mentioned acidic solution to the alkaline solution B at a rate of 5 L / min to obtain a gray precipitated solid-liquid system. Control the pH value of the end point to 10, add 14.8Kg of 30% hydrogen peroxide, and then Aging 4h. Obtain solid-liquid mixed system C. Filter, rinse with 600Kg hot water, and filter. Get wet cake D.

[0059] The wet cake D and water were repulped at a mass ratio of 2:1, 80Kg of lauric acid was added, and the slurry E was obtained by shearing and dispersing. The slurry E was calcined at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen storage capacity | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Oxygen storage capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com