High-performance environment-friendly flame-retardant communication cable sheathing compound and preparation method thereof

A communication cable, a high-performance technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., to achieve the effect of broad market application prospects, controllable response, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

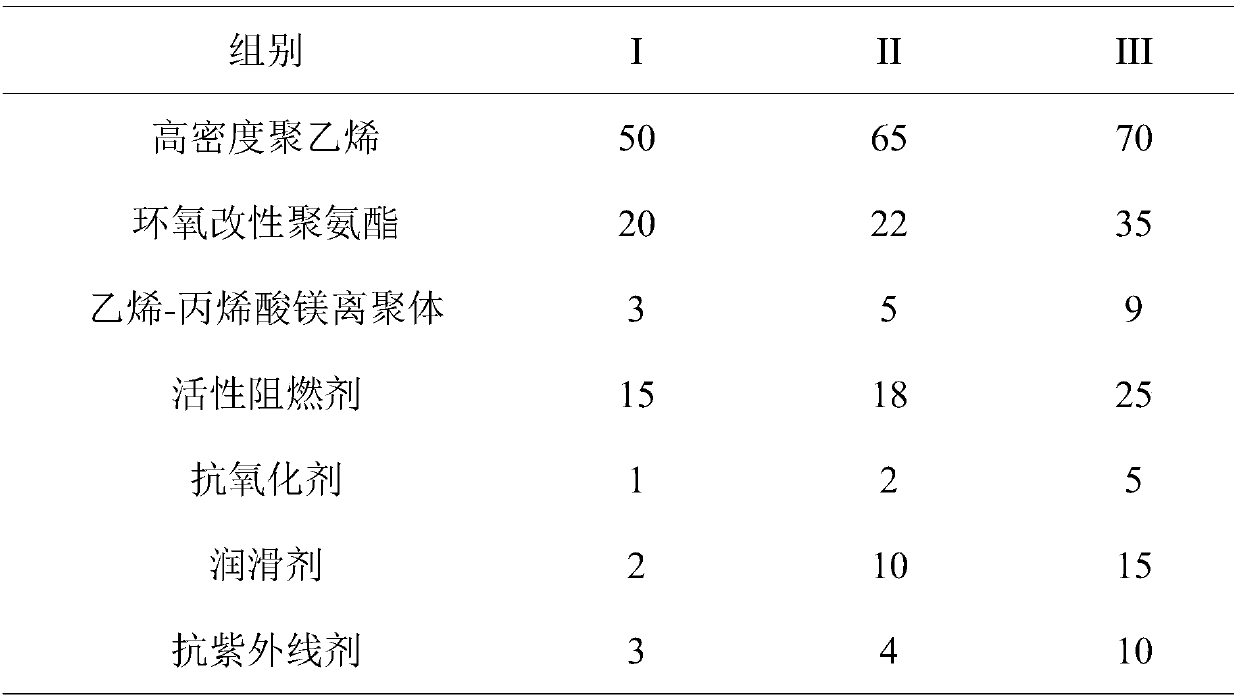

[0022] Example 1: The preparation ratio of each raw material in the high-performance environment-friendly flame-retardant communication cable sheath material

[0023] The raw materials in the high-performance, environment-friendly, flame-retardant communication cable sheathing material were mixed according to the mass fractions described in Table 1, and three groups of high-performance, environment-friendly, flame-retardant communication cable sheathing materials I to III with different mixing ratios were obtained.

[0024] Table 1 High-performance environment-friendly flame-retardant communication cable sheathing materials I-III with different mixing ratios (mass parts)

[0025]

Embodiment 2

[0026] Embodiment 2: the preparation method of high-performance environment-friendly flame-retardant communication cable sheathing material I

[0027] Step 1. Preparation of epoxy-modified polyurethane: Put 30 parts of polyether polyol into the reaction kettle, heat to 120°C for reflux dehydration for 1 hour while stirring, then add 35 parts of toluene diisocyanate when the temperature is lowered to 50°C, and slowly heat up to Stir at 80°C for 4-6 hours to obtain a polyurethane prepolymer; dehydrate 15 parts of diglycidyl tetrahydrophthalate at 80°C for 1-3 hours in vacuum, cool down to 60°C, and then add the Polyurethane prepolymer, 8 parts of 1,4-butanediol, 15 parts of trimethylolpropane, 16 parts of methyl tetrahydrophthalic anhydride and 2,3,6-tris(dimethylaminomethyl ) 1 part of phenol, heated up to 70-90°C, stirred and reacted for 6-8 hours, to obtain the epoxy-modified polyurethane;

[0028] Preparation of active flame retardant: under the protection of nitrogen, add ...

Embodiment 3

[0030] Embodiment 3: the preparation method of high-performance environment-friendly flame-retardant communication cable sheath material II

[0031] Step 1. Preparation of epoxy-modified polyurethane: Put 45 parts of polyether polyol into the reaction kettle, heat to 120°C for reflux dehydration for 1 hour while stirring, then add 55 parts of toluene diisocyanate when the temperature is lowered to 50°C, and slowly heat up to Stir at 80°C for 4-6 hours to obtain a polyurethane prepolymer; dehydrate 25 parts of diglycidyl tetrahydrophthalate at 80°C for 1-3 hours in vacuum, cool down to 60°C, and then add the Polyurethane prepolymer, 12 parts of 1,4-butanediol, 23 parts of trimethylolpropane, 24 parts of methyl tetrahydrophthalic anhydride and 2,3,6-tris(dimethylaminomethyl ) 5 parts of phenol, heated up to 70-90°C, stirred and reacted for 6-8 hours, to obtain the epoxy-modified polyurethane;

[0032] Preparation of active flame retardant: under the protection of nitrogen, add di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com