Trimethyl-silyl polysilsesquioxane particle reinforced type tin-silver-copper composite soldering paste and preparation method thereof

A technology of polysilsesquioxane and trimethylsilyl, applied in welding equipment, manufacturing tools, welding media, etc., can solve interface cracking, difficulty in achieving ideal uniform distribution of reinforcement phase, and poor combination of reinforcement phase and matrix structure and other problems, to achieve the effect of improving mechanical properties, inhibiting formation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

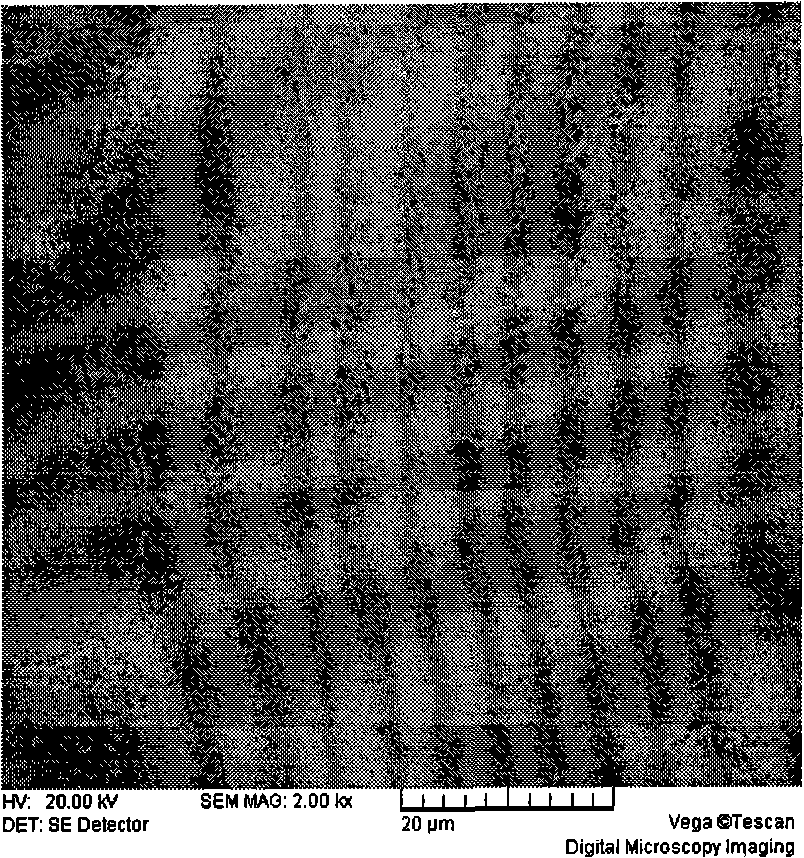

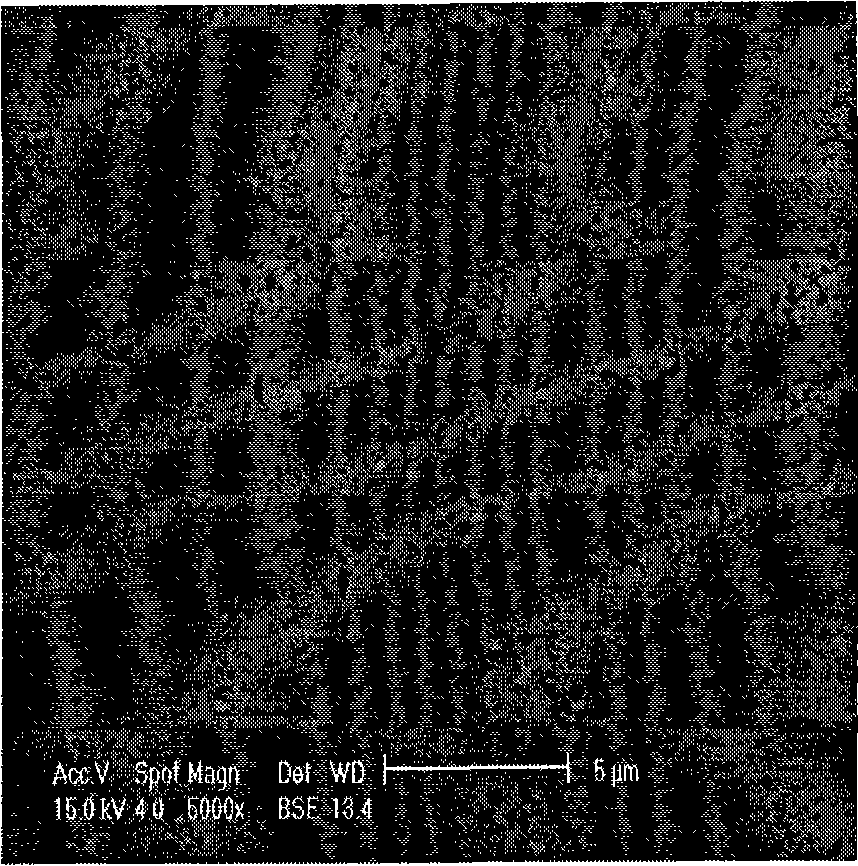

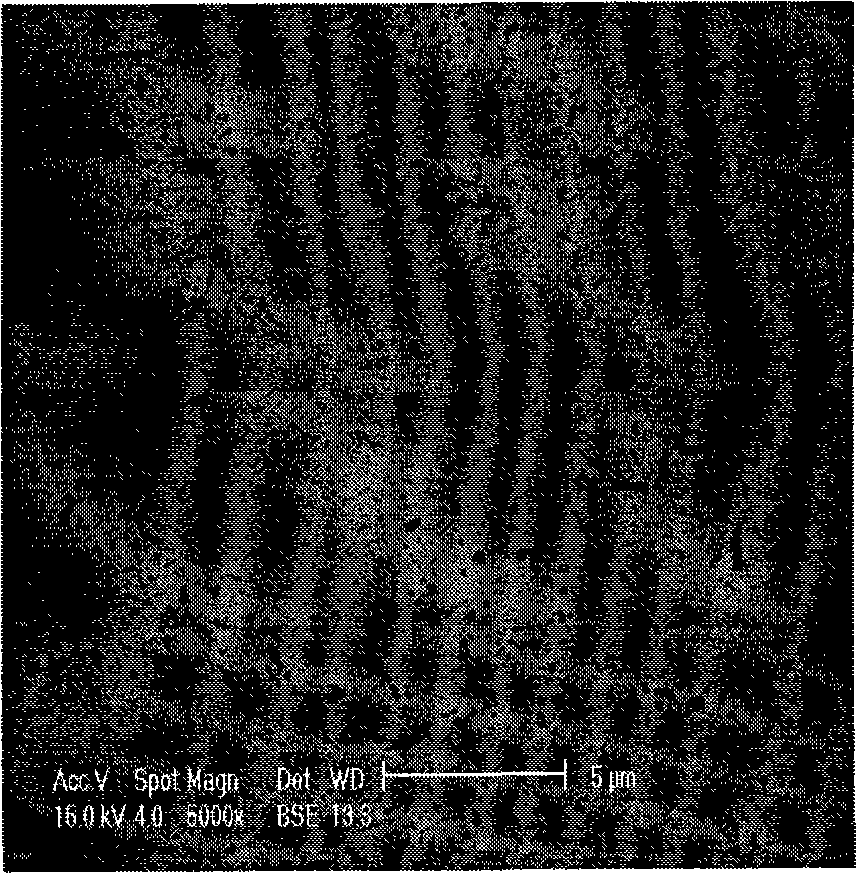

Image

Examples

example 1

[0014] Firstly, the trimethylsilyl polysilsesquioxane particles with a mass ratio of 1% and the no-clean flux are put into a beaker, and after mixing, shake in an ultrasonic cleaner for 1 hour to uniformly disperse the trimethylsilyl polysilsesquioxane. The semisiloxane particles form a slurry. Then put the tin-silver-copper solder paste into a beaker and stir the dispersed slurry by hand for 30 minutes to ensure that the trimethylsilyl polysilsesquioxane particles are evenly mixed with the solder paste to obtain a composite trimethyl Silanyl polysilsesquioxane particle reinforced tin-silver-copper composite solder paste.

example 2

[0016] First, the 2% mass ratio of trimethylsilyl polysilsesquioxane particles and no-clean flux are put into a beaker, and after mixing, shake in an ultrasonic cleaner for 1 hour to uniformly disperse trimethylsilyl polysilsesquioxane. The semisiloxane particles form a slurry. Then put the tin-silver-copper solder paste into a beaker and stir the dispersed slurry by hand for 30 minutes to ensure that the trimethylsilyl polysilsesquioxane particles are evenly mixed with the solder paste to obtain a composite trimethyl Silanyl polysilsesquioxane particle reinforced tin-silver-copper composite solder paste

example 3

[0018] Firstly, the trimethylsilyl polysilsesquioxane particles with a mass ratio of 3% and the no-clean flux are put into a beaker, and after mixing, shake in an ultrasonic cleaner for 1 hour to uniformly disperse the trimethylsilyl polysilsesquioxane. The semisiloxane particles form a slurry. Then put the tin-silver-copper solder paste into a beaker and stir the dispersed slurry by hand for 30 minutes to ensure that the trimethylsilyl polysilsesquioxane particles are evenly mixed with the solder paste to obtain a composite trimethyl Silanyl polysilsesquioxane particle reinforced tin-silver-copper composite solder paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com