Nanostructure-enhanced tin-silver-copper-base leadless compound solder and preparation thereof

A technology of nanostructure and composite brazing material, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of low creep fracture life, poor spreading process performance, high melting point, etc., and achieve long creep fracture life , Improved reliability and creep rupture life, and high shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

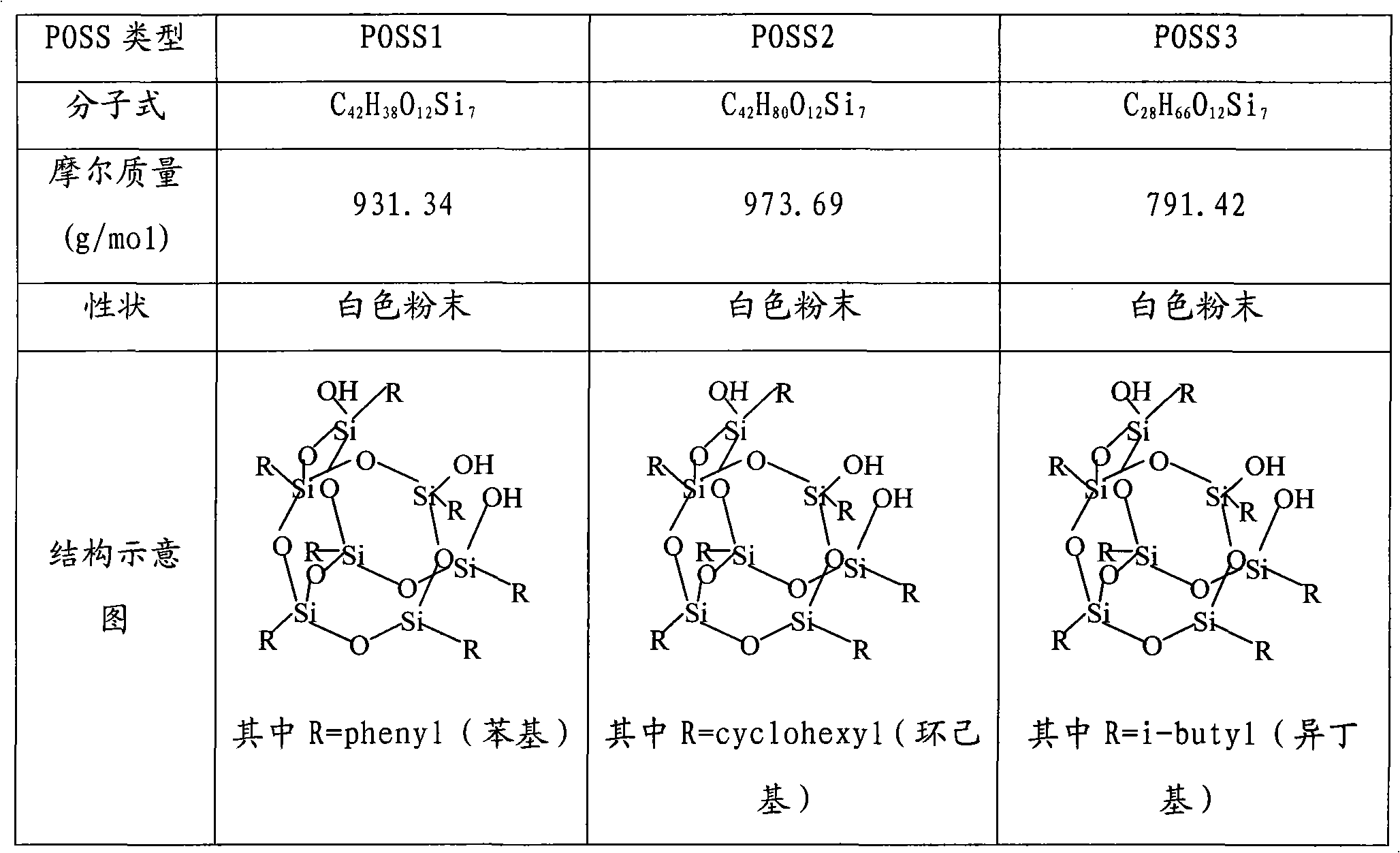

[0020] Take 0.05g of POSS1 with a size of 10-100nm and 4.95g of Sn-3.0Ag-0.5Cu solder paste, mechanically stir for 30min to make a composite solder, store it at low temperature for future use, wherein the weight ratio of POSS1 in the composite solder 1%.

Embodiment 2

[0022] Weigh 0.1g of POSS1 with a size of 10-100nm and 4.9g of Sn-3.0Ag-0.5Cu solder paste, mechanically stir for 30min to make a composite solder, store it at low temperature for future use, wherein, the weight of POSS1 in the composite solder The ratio is 2%.

Embodiment 3

[0024] Weigh 0.15g of POSS1 with a size of 10-100nm and 4.85g of Sn-3.0Ag-0.5Cu solder paste, mechanically stir for 30min to make a composite solder, store it at low temperature for future use, wherein the weight ratio of POSS1 in the composite solder 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com