Tin-silver-copper composite solder paste enhanced by titanium dioxide nanoparticles and preparation method thereof

A nanoparticle and titanium dioxide technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems that cannot meet the reliability requirements of tiny solder joints, and achieve the effects of improving mechanical properties, refining grains, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add nano-titanium dioxide powder (particle size 5-25nm) with a mass fraction of 0.02% to tin-silver-copper lead-free solder paste with a mass ratio of 96.5:3:0.5, and mechanically stir for more than 45 minutes to ensure that the titanium dioxide nanoparticles are uniform Distributed in tin-silver-copper lead-free solder paste, titanium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste can be obtained.

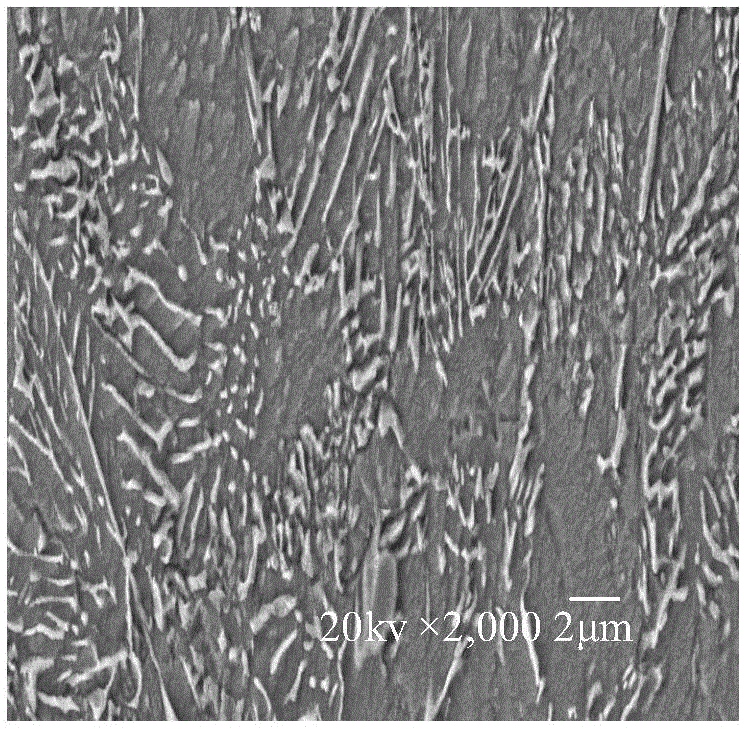

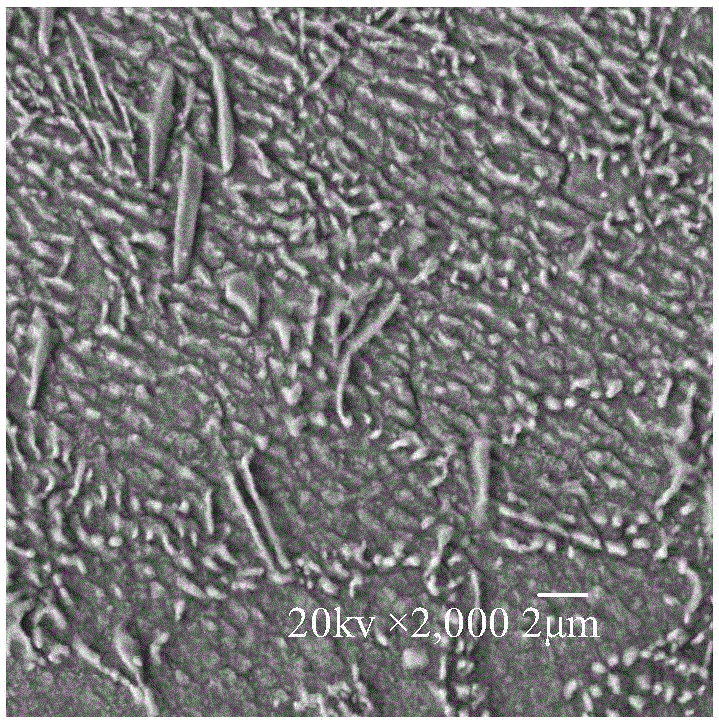

[0023] The scanning electron micrographs of the tin-silver-copper lead-free solder paste without adding nano-titanium dioxide powder and the composite solder paste obtained in this embodiment after reflowing for 60 seconds are as follows: figure 1 and 2 shown. From figure 1 It can be seen that the gray matrix is the tin-rich phase β-Sn, and the white needle-like particles are the intermetallic compound Ag 3 Sn grains, the average size of the grains is 0.52±0.07μm, and the average spacing between the grains is 0.65±0.06μm; from figure 2 It can ...

Embodiment 2

[0025] Add nano-titanium dioxide powder (particle size 5-25nm) with a mass fraction of 0.05% to tin-silver-copper lead-free solder paste with a mass ratio of 96.5:3:0.5, and mechanically stir for more than 45 minutes to ensure that the titanium dioxide nanoparticles are uniform Distributed in tin-silver-copper lead-free solder paste, titanium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste can be obtained.

[0026] The scanning electron microscope image of the composite solder paste obtained in this embodiment after reflow for 60s is as follows image 3 As shown, the gray matrix is the tin-rich phase β-Sn, and the white particles are the intermetallic compound Ag 3 The average grain size of Sn grains is 0.36±0.05 μm, and the average distance between grains is 0.42±0.03 μm. Compared with Example 1, the structure of the composite solder paste in this example is further refined.

Embodiment 3

[0028] Add nano-titanium dioxide powder (particle size 5-25nm) with a mass fraction of 0.1% to tin-silver-copper lead-free solder paste with a mass ratio of 96.5:3:0.5, and mechanically stir for more than 45 minutes to ensure that the titanium dioxide nanoparticles are uniform Distributed in tin-silver-copper lead-free solder paste, titanium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste can be obtained.

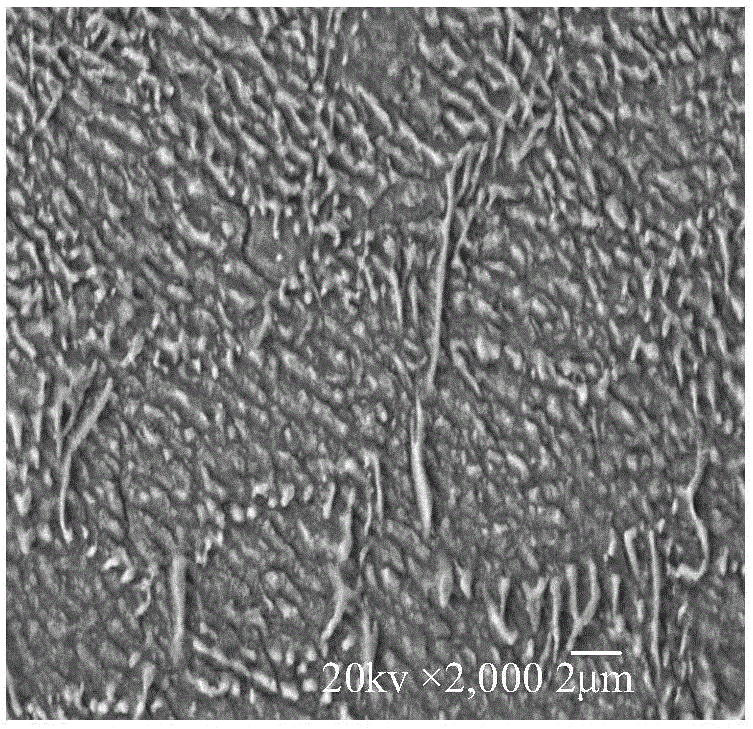

[0029] The scanning electron microscope image of the composite solder paste obtained in this embodiment after reflow for 60s is as follows Figure 4 As shown, the gray matrix is the tin-rich phase β-Sn, and the white particles are the intermetallic compound Ag 3 The average size of the Sn grains is 0.23±0.02 μm, and the average distance between the grains is 0.31±0.04 μm; compared with Example 2, the structure of the composite solder paste in this example is more refined.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com