Tin-silver-copper plating solution, plating film containing the same, and method for forming the plating film

A technology of electroplating solution and film coating, which is applied in the direction of assembling printed circuits, electrodes, plating tanks, etc. of electrical components, and can solve the problems of difficult and unobtainable electroplating solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0117] Hereinafter, the present invention will be explained in more detail with experimental examples. As long as the gist of the present invention is not exceeded, the present invention is not limited to the following experimental examples.

[0118]In order to judge the effects of the electroplating solution, electroplating method, electroplating film, and welding method related to the present invention, the electroplating film electroplated by the electric power electroplating method of the present invention is used to use the electroplating solution of the present invention. Appearance, melting point, experimental determination. In particular, using this electroplated film, soldering is performed by the soldering method according to the embodiment of the present invention in the reflow soldering method. Experiment and measure the bonding strength and solder wettability of this electroplated film. The electroplating solution containing tin, silver, and copper according to the em...

Embodiment 1a

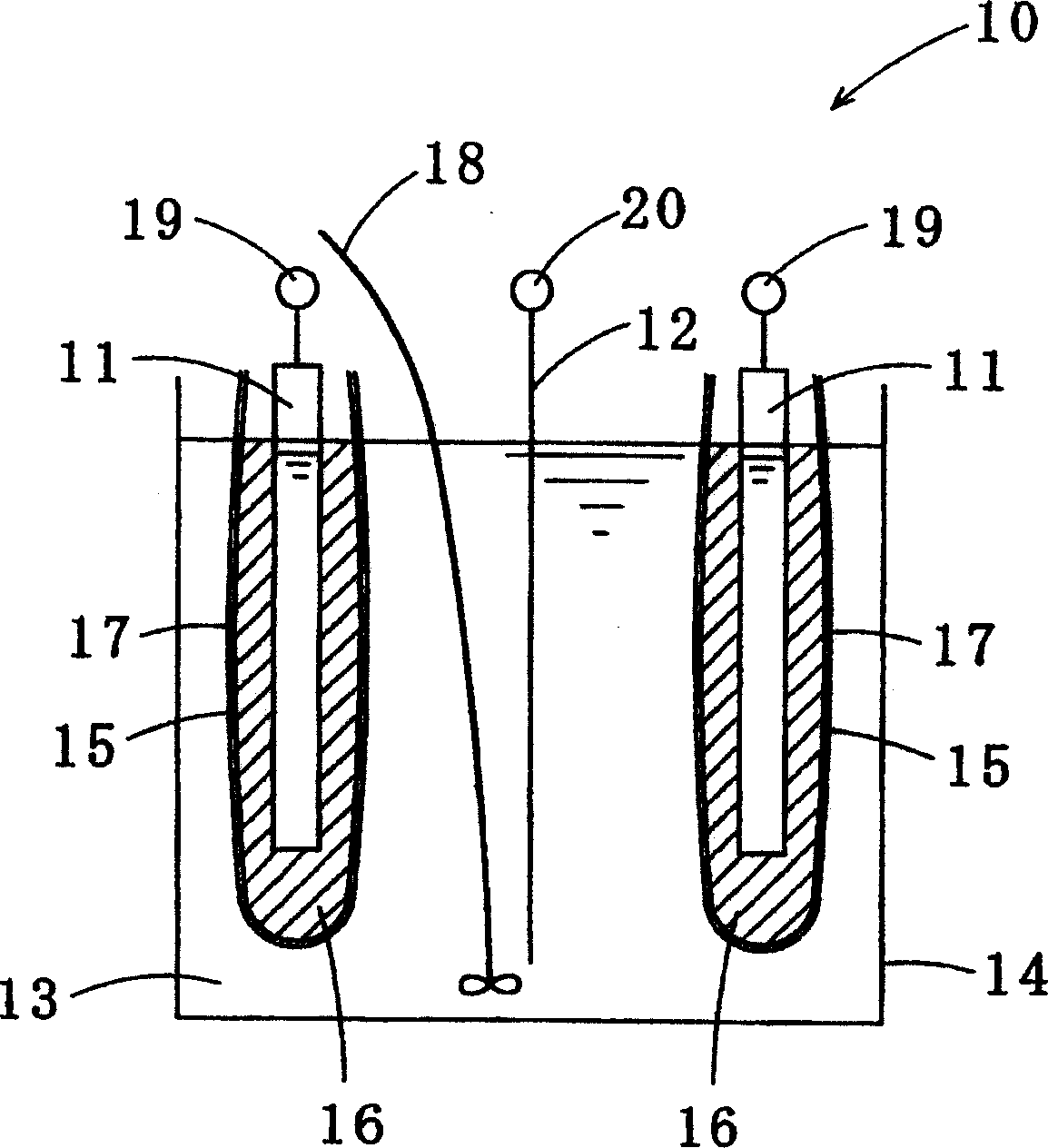

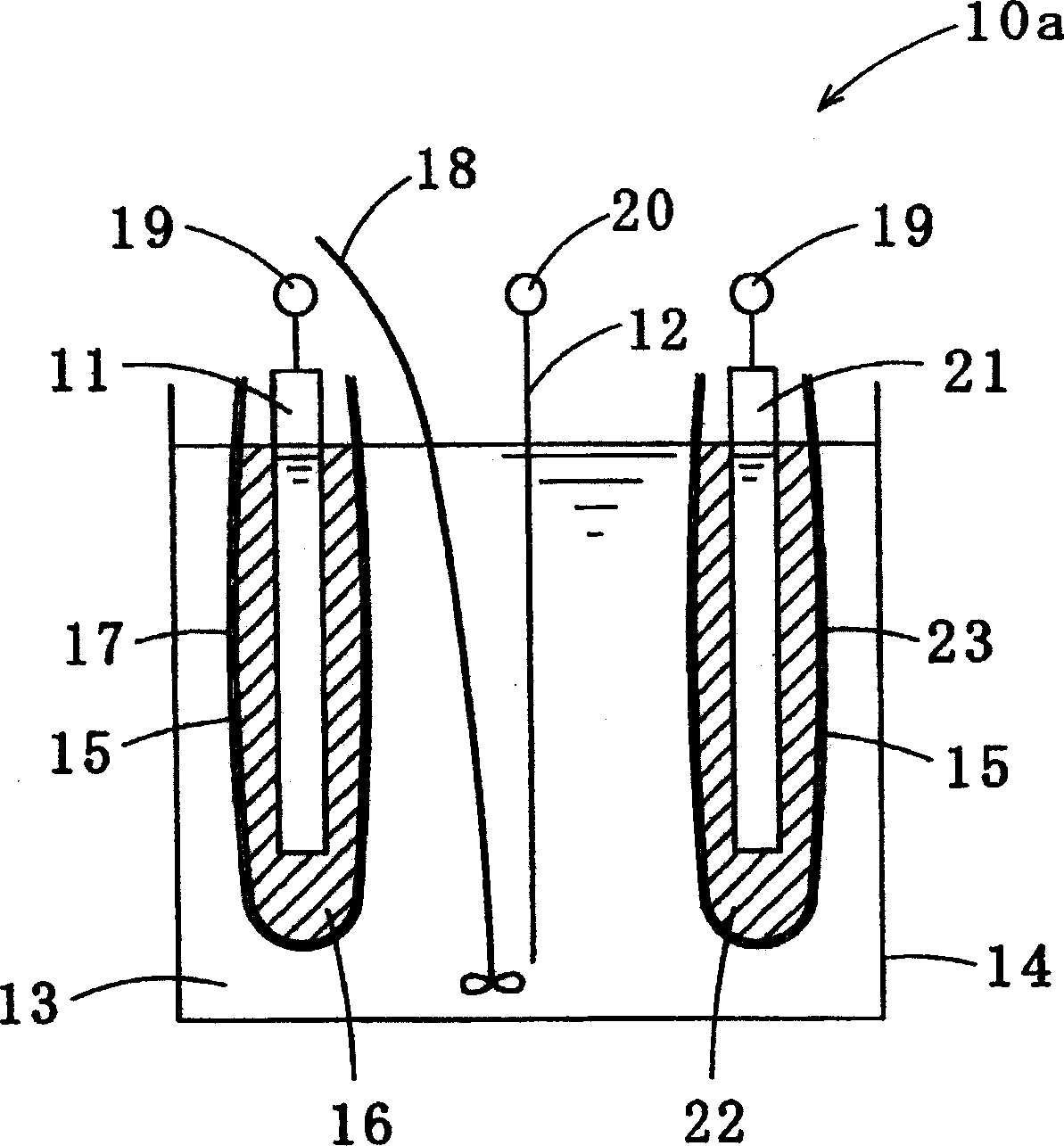

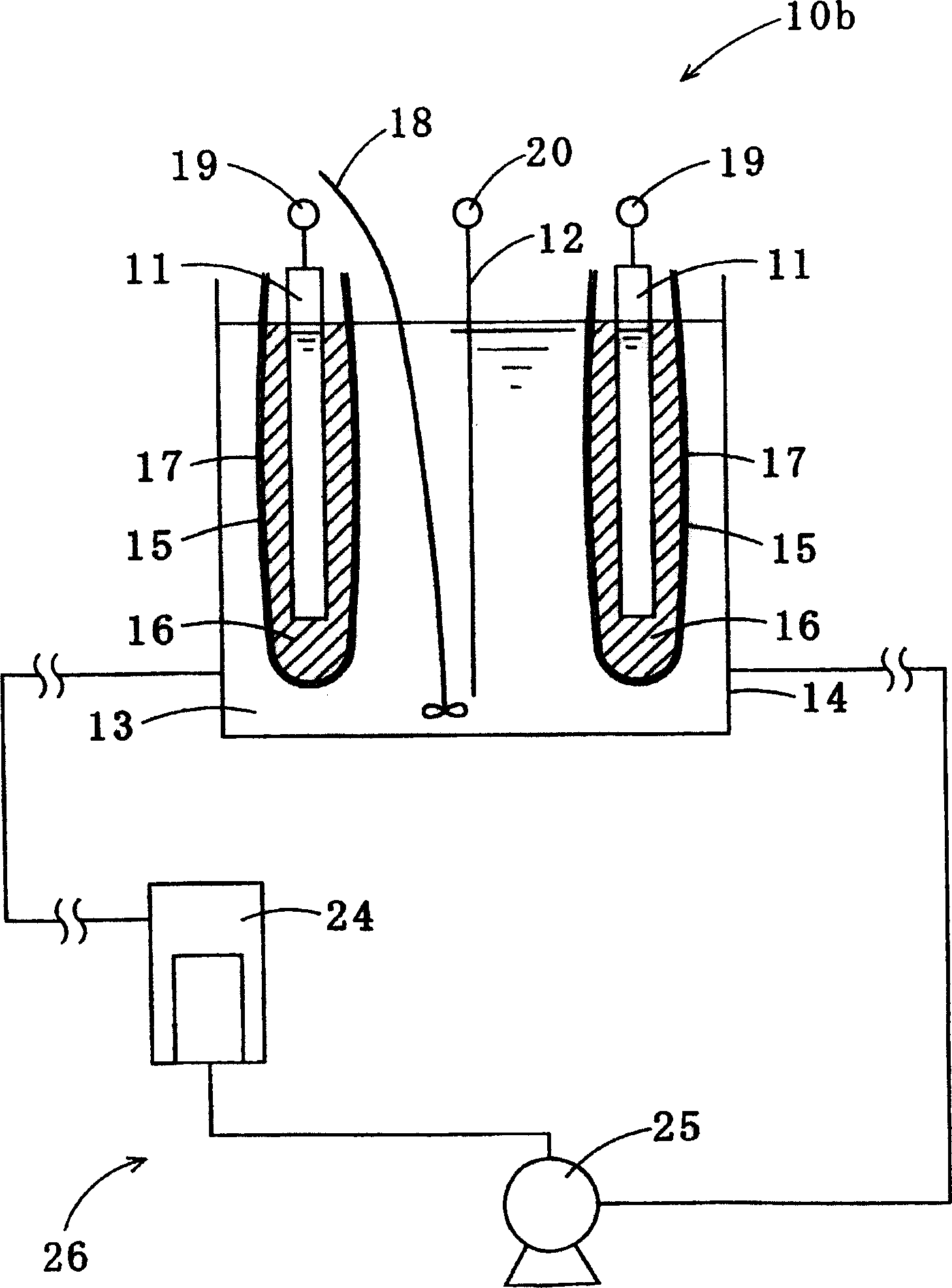

[0130] Using the electroplating solution a shown in Table 1, electroplating was performed using the following electrolytic plating method of the present invention to produce an electroplated film.

[0131] Put 500ml of electroplating solution a in a beaker, prepare 2 pure Sn cuboid ingots as soluble anodes, draw out 2 wires from the ten sides of the rectifier, and fix them on the ingots with clips. Lead a wire from one side of the rectifier, and fix it on the plated object as well. (0.3 dm 2 The current density of 42 alloy test piece (Ni42wt%, Fe58wt%)) is 5.8A / dm 2 , True current waveform, 18℃, electroplating for 216 seconds. On the 42-degree alloy test piece, a semi-bright electroplated film with a good film thickness of 8 μm was obtained. The 42 alloy test piece with electroplating film was rinsed thoroughly with tap water, then rinsed with pure water, and then dried.

[0132] In the obtained electroplated film, the metal content, appearance, bonding strength, solder wettabilit...

experiment example 1b

[0149] In addition to the 0.3 dm in Experimental Example 1a 2 0.3 dm for 42 alloy test piece 2 Except that the copper test piece was replaced, the other was electroplated in the same manner as in Experimental Example 1a.

[0150] The results of Experimental Example 1b are shown in Table 4. The Cu content and the silver content in the coating film were not measured, but the composition is considered to be substantially the same as that of Experimental Example 1a.

[0151] The bonding strength with the copper-clad test substrate made of glass epoxy is very good, and the other test results are almost the same as those of Experimental Example 1a, the appearance is acceptable, and the melting point is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com