High-speed bullet train brake disc body and casting method and heat treatment method thereof

A heat treatment method and technology for high-speed trains, applied in brake discs, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of increased yield point and tensile strength, decreased plasticity and impact toughness, and cannot be infinitely solid solution, reaching low Modulus of elasticity and coefficient of thermal expansion, the effect of preventing the generation and propagation of cracks, and improving the microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

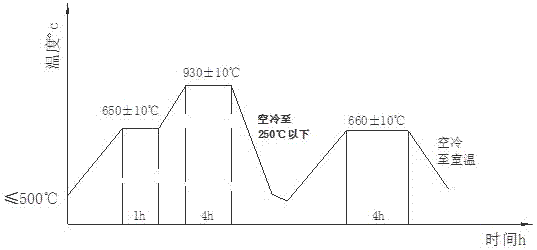

[0041] Embodiment 1: cast and heat treat the brake disc body of high-speed train according to the following steps

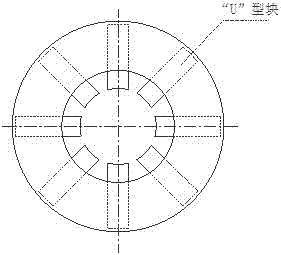

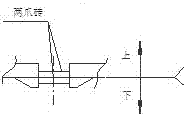

[0042] (1) Structural design of the brake disc body: the brake disc body is cast, and the upper and lower disc surfaces of the disc body are parallel to each other. Linked by "U" blocks; the total outer diameter of the brake disc body is 650mm, leaving a friction surface of 140mm from the outer circle edge, and the rest are processed into holes; the thickness of the upper and lower disc surfaces of the brake disc body Equal, 20mm; the distance between the upper disc surface and the lower disc surface of the brake disc body is 60mm; the length of the "U" block is 200mm, the width is 60mm, and the thickness is 60mm, and the arc of the "U" block is the same radius as the disc body The arc size is the same;

[0043] (2) Material design of the brake disc body: the controlled chemical composition range during furnace melting is as follows: C 0.20, Si 0.40, Mn0.80, P≤0...

Embodiment 2

[0047] Embodiment 2: cast and heat treat the brake disc body of high-speed train according to the following steps

[0048] (1) Structural design of the brake disc body: the brake disc body is cast, and the upper and lower disc surfaces of the disc body are parallel to each other. Linked by "U" blocks; the total outer diameter of the brake disc body is 675mm, the friction surface is 150mm away from the outer circle edge, and the rest are processed into holes; the thickness of the upper and lower disc surfaces of the brake disc body Equal, 22.5mm; the distance between the upper disc surface and the lower disc surface of the brake disc body is 62.5mm; the length of the "U" block is 210mm, the width is 70mm, and the thickness is 62.5mm. The arc of the "U" block and the disc The size of the arc with the same radius is the same;

[0049] (2) Material design of the brake disc body: the controlled chemical composition range during furnace melting is as follows: C 0.25, Si 0.55, Mn1.0...

Embodiment 3

[0053] Embodiment 3: cast and heat treat the brake disc body of high-speed train according to the following steps

[0054] (1) Structural design of the brake disc body: the brake disc body is cast, and the upper and lower disc surfaces of the disc body are parallel to each other. Linked by "U" blocks; the total outer diameter of the brake disc body is 700mm, and the friction surface is 160mm away from the outer circle edge, and the rest are processed into holes; the thickness of the upper and lower disc surfaces of the brake disc body is Equal, 25mm; the distance between the upper disc surface and the lower disc surface of the brake disc body is 65mm; the length of the "U" block is 220mm, the width is 80mm, and the thickness is 65mm. The arc of the "U" block is the same radius as the disc body The arc size is the same;

[0055] (2) Material design of the brake disc body: the controlled chemical composition range during furnace melting is as follows: C 0.30, Si 0.7, Mn1.30, P≤...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com