Ceramsite sand used for casting and preparation method thereof

A technology of ceramsite sand and polytetrafluoroethylene, applied in the field of foundry materials, can solve the problems of polluted environment, bad grain shape of silica sand and high thermal expansion rate of silica sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

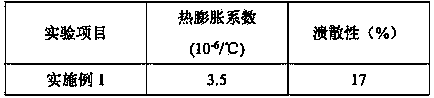

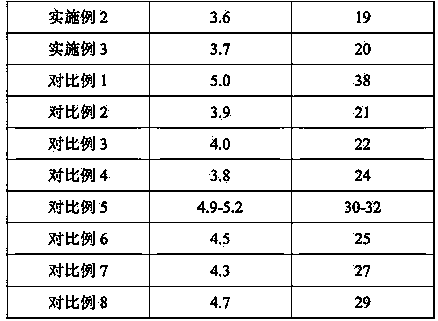

Examples

preparation example Construction

[0026] A kind of preparation method of above-mentioned casting ceramsite sand, comprises the following steps:

[0027] a. Grinding the raw materials into a powder with a particle size of 500-800 meshes by pulverizing and ball milling, and stirring and mixing according to the parts by weight of the formula to obtain a powder mixture;

[0028] b. Add the powder mixture into the ball making device, spray the pre-prepared aqueous solution into the ball making device with a sprayer, and make the powder mixture into balls with a particle size of 30-60 mesh and a water content of 1.5% Granular semi-finished products;

[0029] c. Dry the pelletized semi-finished product until its water content is 0.2%, and then place it in a sintering rotary kiln for sintering at a sintering temperature of 1550-1700°C and a sintering time of 3.5-5.0 hours;

[0030] d. After the roasting is completed, crush and sieve through a 30-60 mesh sieve to obtain the ceramsite sand.

Embodiment 1

[0032] A kind of ceramsite sand for foundry, comprises following raw material: 30 mass parts of aluminum oxide, 60 mass parts of silicon dioxide, 5 mass parts of boron oxide, 4 parts of polytetrafluoroethylene, 8 parts of calcium lignosulfonate, zirconia Fiber 2 servings. The polytetrafluoroethylene has a weight average molecular weight of 5 million. The length of the zirconia fibers is 3-8 μm. A kind of preparation method of above-mentioned casting ceramsite sand, comprises the following steps:

[0033] a. Grinding the raw materials into a powder with a particle size of 650 meshes by means of pulverization and ball milling, and stirring and mixing according to the parts by weight of the formula to obtain a powder mixture;

[0034] b. Add the powder mixture into the ball making device, spray the pre-prepared aqueous solution into the ball making device with a sprayer, and make the powder mixture into a spherical semi-finished product with a particle size of 50 mesh and a wat...

Embodiment 2

[0038] A kind of ceramsite sand for casting, comprising following raw materials: 40 parts by mass of aluminum oxide, 55 parts by mass of silicon dioxide, 10 parts by mass of boron oxide, 3 parts of polytetrafluoroethylene, 10 parts of calcium lignosulfonate, zirconia Fiber 1 serving. The polytetrafluoroethylene has a weight average molecular weight of 1 million. The length of the zirconia fibers is 3-8 μm.

[0039] A kind of preparation method of above-mentioned casting ceramsite sand, comprises the following steps:

[0040] a. Grinding the raw materials into a powder with a particle size of 500 meshes by means of pulverization and ball milling, and stirring and mixing according to the parts by weight of the formula to obtain a powder mixture;

[0041] b. Add the powder mixture into the ball making device, spray the pre-prepared aqueous solution into the ball making device with a sprayer, and make the powder mixture into a spherical semi-finished product with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com