Process for synthesizing biphase nanometer fuel battery cathode material

A fuel cell cathode and synthesis method technology, which is applied to fuel cell parts, battery electrodes, chemical instruments and methods, etc., can solve the problems of thermal expansion coefficients not close, chemical incompatibility, etc., achieve performance improvement, and simple synthesis method , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

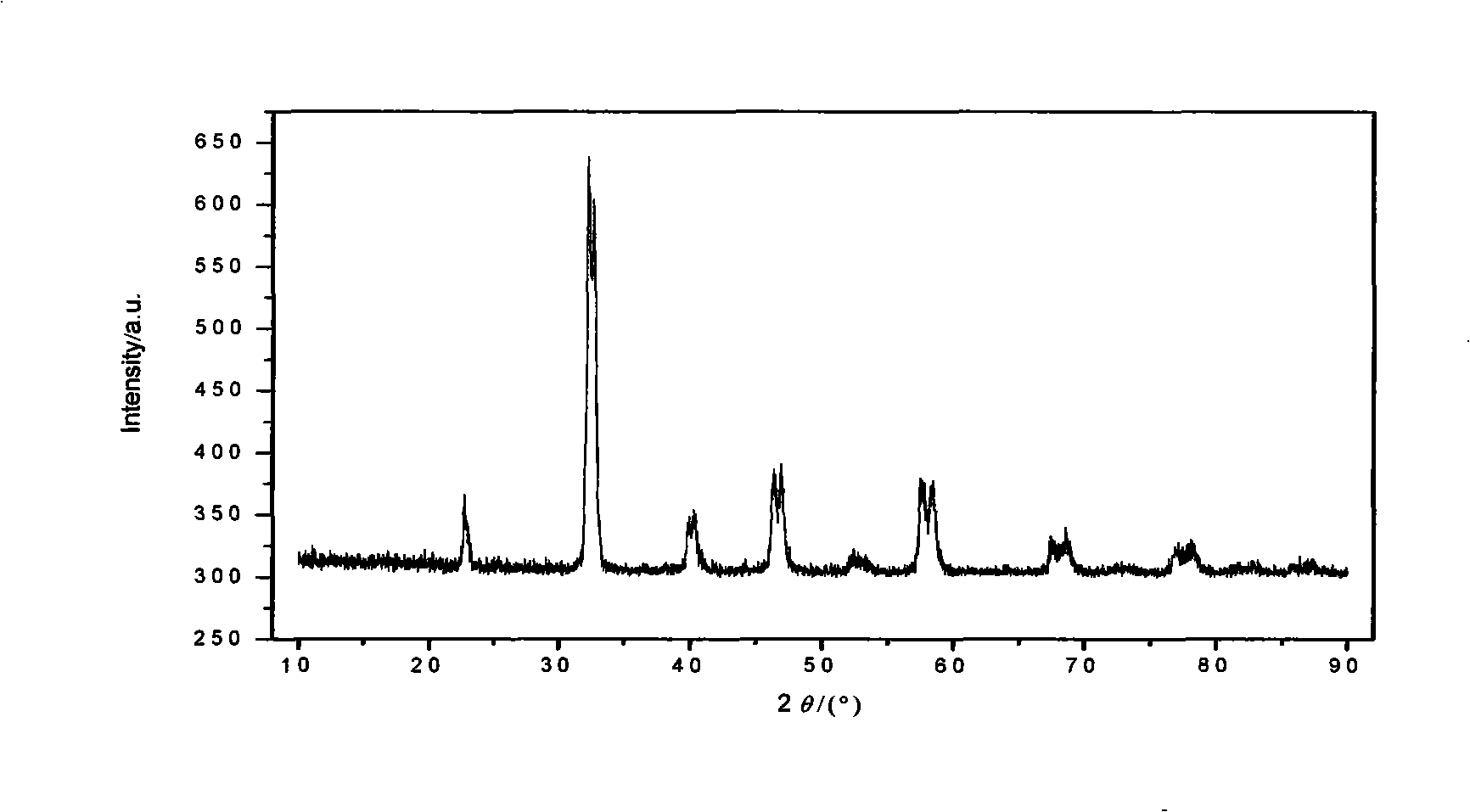

[0026] Combine lanthanum nitrate, strontium nitrate, iron nitrate, cobalt nitrate, etc. according to La 0.6 Sr 0.4 Co 0.2 Fe 0.8 O 3 The stoichiometric ratio is mixed into a solution, and the quantitative EDTA is dissolved into the ammonia aqueous solution according to the synthesis requirements to form a clear solution, and an appropriate amount of ethylene glycol is added. All the above solutions are mixed and heated and stirred at 70°C with a constant temperature magnetic stirrer. Keep the pH of the solution at 9 until a sol is formed. Dry the sol in a drying oven at 170°C for 8 hours to obtain a dry gel. Manually grind the gel to make the precursor particles have a certain surface size. In a resistance furnace at 900°C After heating for 2 hours to obtain the nanomaterials, such as image 3 XRD pattern shown.

Embodiment 2

[0028] Combine lanthanum nitrate, strontium nitrate, iron nitrate, cobalt nitrate, etc. according to La 0.6 Sr 0.4 Co 0.2 Fe 0.8 O 3 The stoichiometric solution is mixed with the solution with citric acid as the complexing agent. The amount ratio of citric acid to all metal ions is 1.1. Add appropriate amount of ethylene glycol and heat and stir at 80°C with a constant temperature magnetic stirrer. The pH of the solution is 9 until a sol is formed. The sol is dried in a drying oven at 170°C for 8 hours to obtain a dry gel. The dry gel is mechanically ball-milled to make the particles have a certain specific surface size and heated at 900°C in a resistance furnace 2 Hours to obtain the nanomaterial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com