Resin composition, prepreg, laminated board and metal foil-coated laminated board

A resin composition and prepreg technology, applied in the field of prepreg, laminate and metal foil-clad laminate, can solve the problems of inapplicability, different warpage requirements, cracking of welding parts, etc. The effect of low heat resistance and moisture and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] Hereinafter, the present disclosure will be specifically described using examples.

[0068]

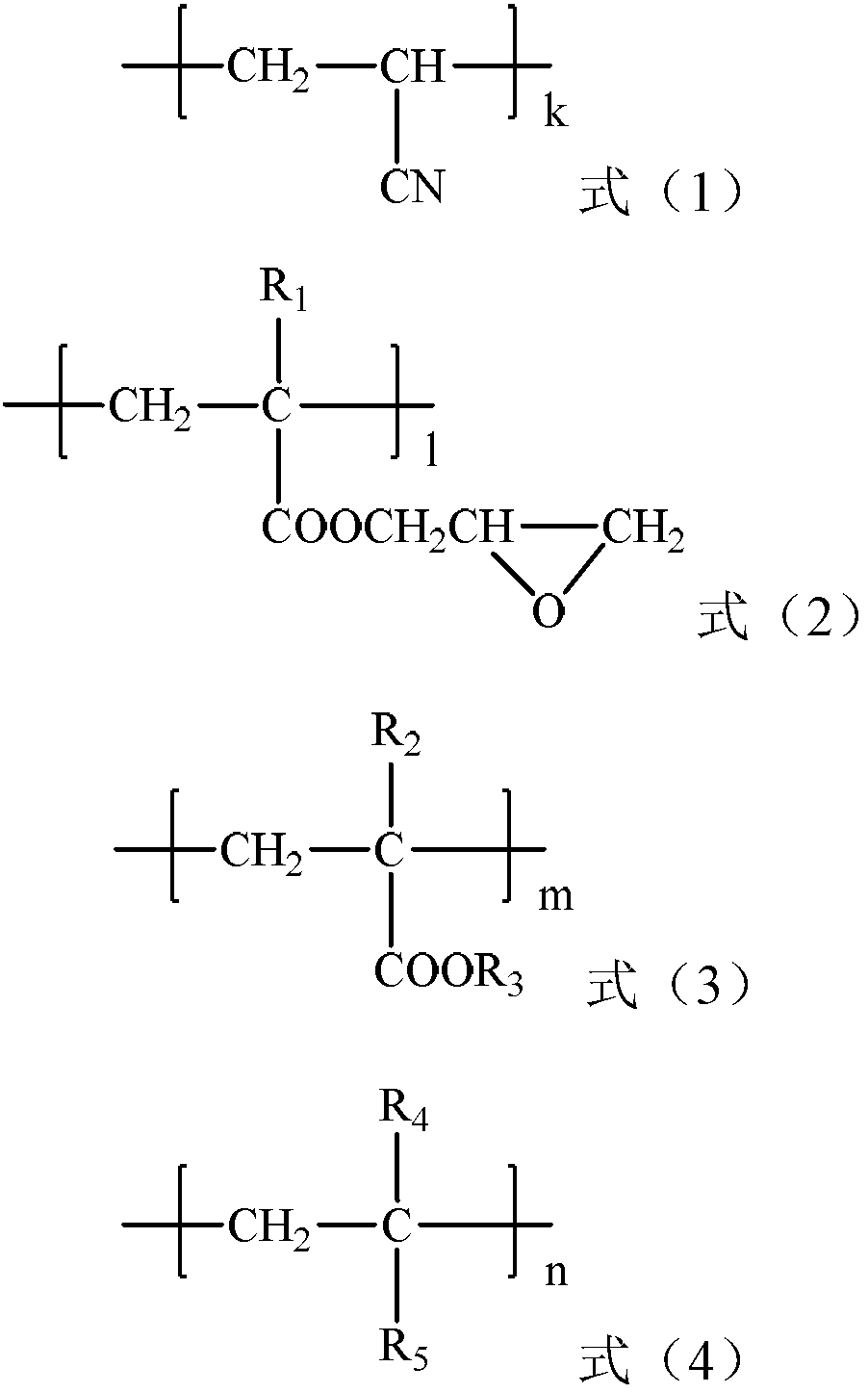

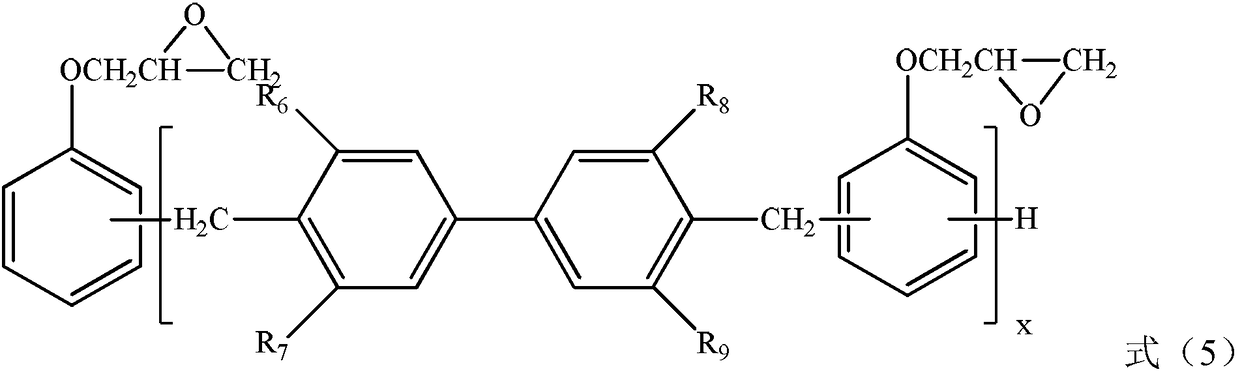

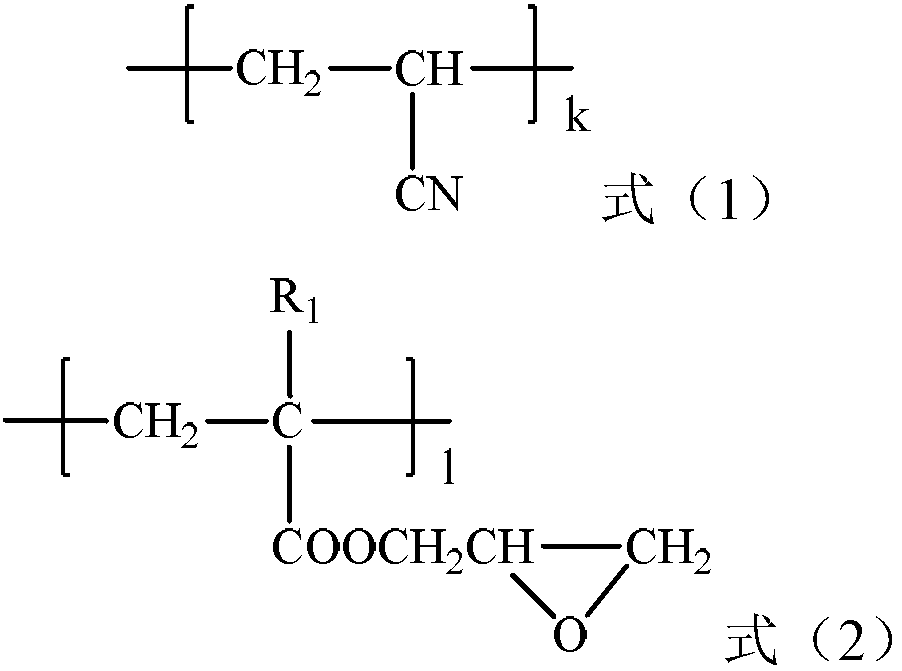

[0069] Epoxy resin (A1): biphenyl aralkylene type epoxy resin ("NC-3000-H" manufactured by Nippon Kayaku Co., Ltd., structure represented by formula (5))

[0070] Epoxy resin (A2): naphthyl type epoxy resin ("HP-6000" manufactured by DIC Corporation, structure represented by formula (6))

[0071]

[0072] R in formula (6) 10 is a hydrogen atom, methyl or ethyl.

[0073] Epoxy resin (A3): bisphenol A epoxy resin ("828US" manufactured by Mitsubishi Chemical Corporation)

[0074] Cyanate resin (B1): Bisphenol A type cyanate resin ("BA-3000S" manufactured by Lonza Corporation)

[0075] Cyanate resin (B2): phenolic cyanate resin ("PT-30S" manufactured by Lonza Corporation)

[0076] Bismaleimide resin (C1): bis(3-ethyl-5-methyl-4-bismaleimidophenyl)methane ("TY-2002" manufactured by Tianyi Chemical Co., Ltd.)

[0077] Bismaleimide resin (C2): diphenylmethane type bismaleimi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com