Resin composition, prepreg, laminated board and laminated board covered with metal foil

A resin composition and prepreg technology, applied in metal layered products, coatings, layered products, etc., can solve the problems of poor mechanical properties of cured products, affect moisture and heat resistance, aggravate warpage, etc., and achieve improvement. Effects of reduced interlayer adhesion and adhesion to metal foil, good heat resistance, and low humidity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

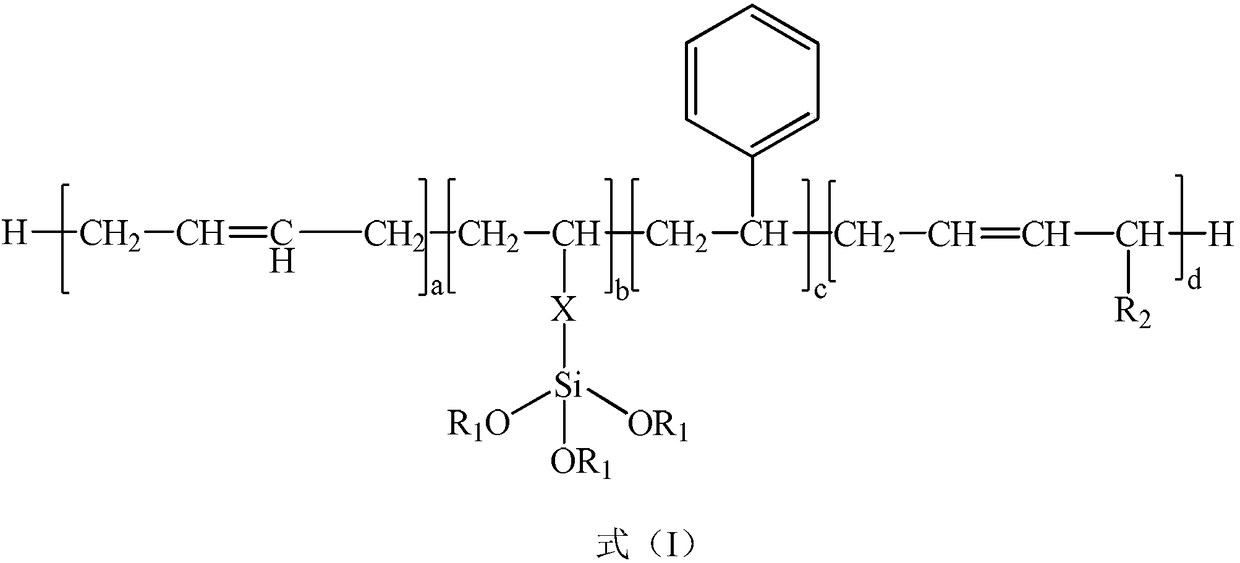

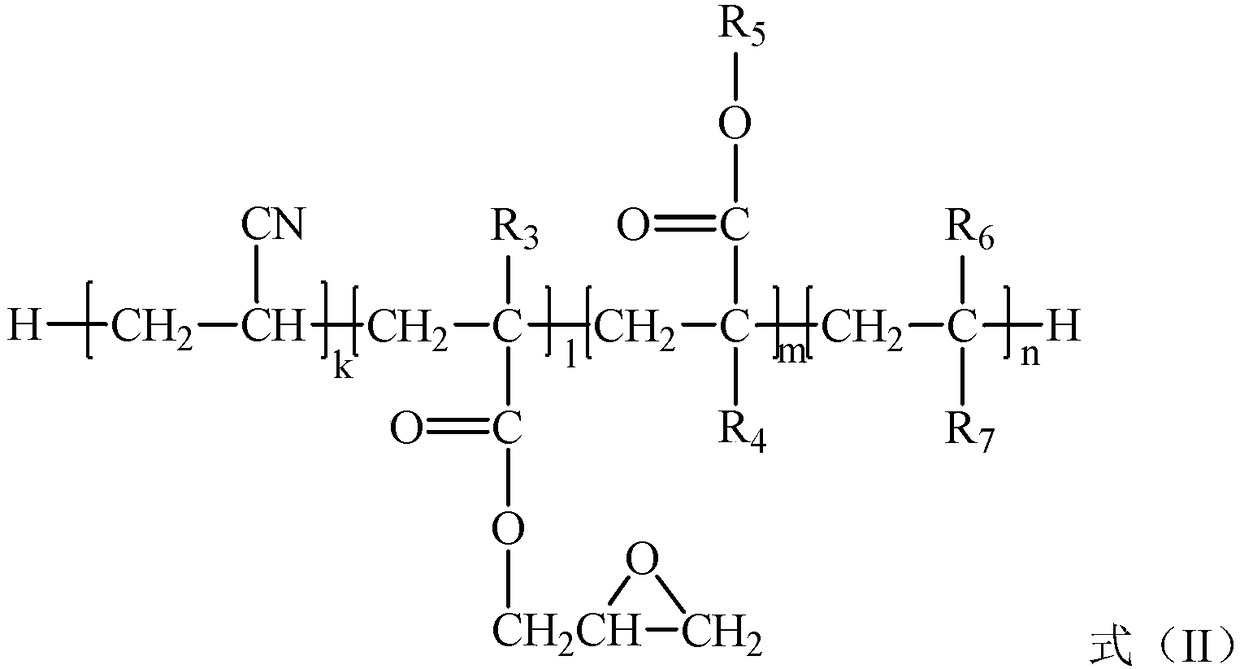

Method used

Image

Examples

Embodiment

[0080] Hereinafter, the present disclosure will be specifically described using examples.

[0081] The examples and the comparative examples are only different in the types of compounding materials used, and the preparation process of the resin composition and the prepreg obtained by using it, laminated board and metal foil-clad laminated board are the same, so no difference will be described.

[0082] (Raw material, see table 1)

[0083] Table 1 Resin Composition Raw Materials Used in Examples and Comparative Examples

[0084]

[0085]

[0086] In the examples of the present invention and the comparative examples, each component is calculated as solid matter.

[0087] (Prepreg)

[0088] Epoxy-modified acrylate resin (A), epoxy resin (D), cyanate resin (E), bismaleimide resin (F), organic metal salt accelerator and imidazole accelerator, according to The mass parts shown in table 2 are combined, dissolved and diluted with dimethylformamide and methyl ethyl ketone, aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com