Non-linear voltage resistance

A non-linear resistance, voltage technology, applied in the direction of varistor, overvoltage protection resistor, varistor core, etc., can solve the problem that the miniaturization of voltage non-linear resistance cannot be realized, and high temperature sintering above 550 ℃ is required. , the deterioration of voltage characteristics and charging life characteristics, etc., to achieve the effects of good current-voltage characteristics and charging life characteristics, high energy absorption capacity, and low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

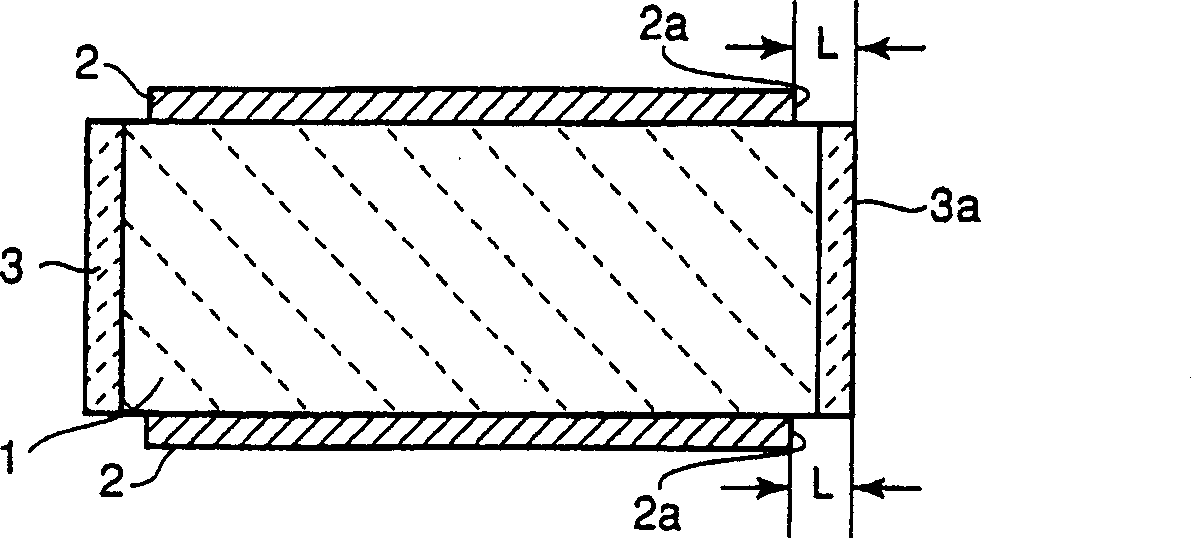

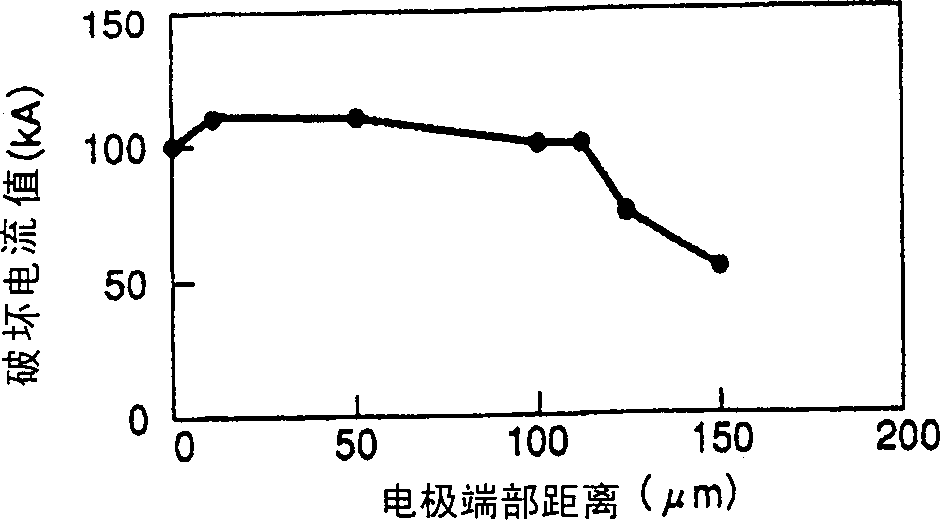

[0078] A voltage non-linear resistor was manufactured by preparing a sintered body, forming a side high-resistance layer, and forming an electrode as described below. Production of sintered body

[0079] In zinc oxide (ZnO) as the main component, bismuth oxide (Bi 2 o 3 ), manganese oxide (MnO 2 ), each 1 mol% of cobalt oxide (Co 2 o 3 ), nickel oxide (NiO), antimony trioxide (Sb 2 o 3), mixing the raw materials with water and organic binders in a mixing device to prepare a mixed slurry. Next, after spraying and granulating the mixed slurry with a spray dryer, a predetermined weight of the granulated powder is put into a metal mold and pressurized with a predetermined pressure to form, for example, a disc with a diameter of 50 mm. Then, it is heat-treated in air at 400-500°C to degrease, and then sintered at 1200°C to make a disk-shaped sintered body. Formation of side high resistance layer

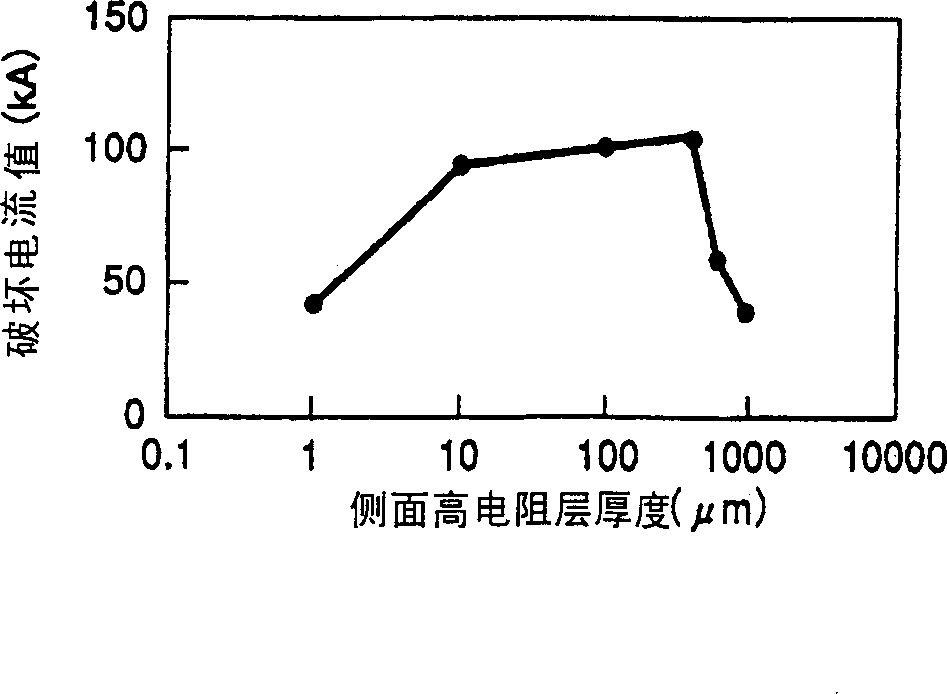

[0080] First, mix bismuth-based glass powder with an organic binder and wate...

Embodiment 2

[0096] A voltage non-linear resistor was manufactured by forming a side high-resistance layer and forming an electrode as described below. Formation of side high resistance layer

[0097] First, mix bismuth-based glass powder with organic binder and water to prepare 16 kinds of mixed pastes. The bismuth-based glass powder contains Bi as a main component and contains Zn, B, Si, Al, and Ba in predetermined amounts as oxides.

[0098] In addition, in the bismuth-based glass of a specific composition composed of the above-mentioned components, a predetermined amount of cordierite (Mg 2 Al 4 Si 5 o 18 ) filler and mullite (Al 6 Si 2 o 13 ) filler, the mixture was mixed with an organic binder and water, and prepared into 10 kinds of mixed slurry.

[0099] Next, each of the above-mentioned mixed slurries was applied to the side surfaces of the same disk-shaped sintered body as in Example 1, and fired to form side high-resistance layers. electrode formation

[0100] The surf...

Embodiment 3

[0113] A voltage non-linear resistor was manufactured by forming a side high-resistance layer and forming an electrode as described below. Formation of side high resistance layer

[0114] First, the following four types of mixed slurries for forming side high-resistance layers were prepared.

[0115] (1) Bismuth-based glass powder is mixed with an organic binder and water to prepare a first mixed slurry. The composition of the bismuth-based glass powder is mainly composed of Bi, containing Zn, B, Si, Al, Ba, and its content is calculated as ZnO=10wt%, B 2 o 3 =5wt%, SiO 2 =1.0wt%, Al 2 o 3 = 1.0 wt%, BaO = 1.0 wt%.

[0116] (2) Add 10wt% cordierite (Mg 2 Al 4 Si 5 o 18 ) filler, the mixture is mixed with an organic binder and water to prepare a second mixed slurry. The composition of the above-mentioned bismuth-based glass powder is mainly composed of Bi, containing Zn, B, Si, Al, Ba, and its content is calculated as ZnO=10wt%, B 2 o 3 =5wt%, SiO 2 =1.0wt%, Al 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com