Preparation method of graphene-modified PVA composite material

A graphene modification and composite material technology, applied in the field of polyvinyl alcohol modification, can solve problems such as widening and inability to process PVA, and achieve the effects of expanding application fields, excellent barrier properties, and excellent degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the described graphene-modified PVA composite material is to use graphene as a modifying agent, carry out pre-plasticizing treatment with starch, PVA, plasticizer and auxiliary agent, and then carry out melting intercalation plasticizing extrusion, A graphene-modified PVA composite material is obtained; the temperature during the melting and intercalation plasticizing extrusion is 155±10° C.

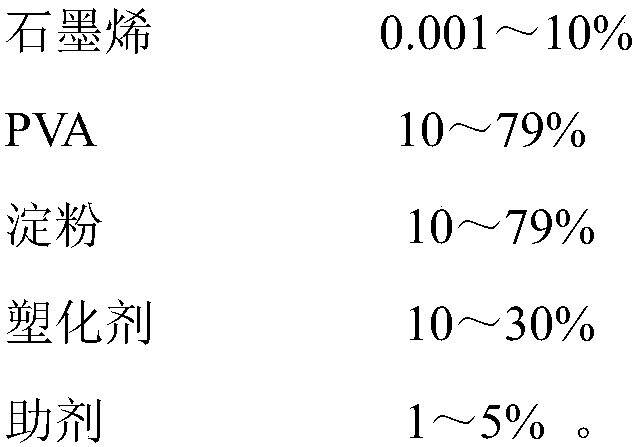

[0035] The weight percentage of used raw material is composed as follows:

[0036]

[0037] The graphene is an oily liquid with a 6-layer benzene ring structure and a sheet diameter of 500 nm.

[0038] The degree of polymerization of the PVA is 500, the degree of alcoholysis is 75%, and the particle size of the powder is 60 mesh.

[0039] The plasticizer is a mixture of glycerol, sodium alginate, ethylenediformamide and triacetin, and the mixing mass ratio is 3:5:1:2.

[0040] The auxiliary agent is a mixture of lubricant, antioxidant and antibacteri...

Embodiment 2

[0046] The preparation method of the described graphene-modified PVA composite material is to use graphene as a modifying agent, carry out pre-plasticizing treatment with starch, PVA, plasticizer and auxiliary agent, and then carry out melting intercalation plasticizing extrusion, A graphene-modified PVA composite material is obtained; the temperature during the melting and intercalation plasticizing extrusion is 205±15° C.

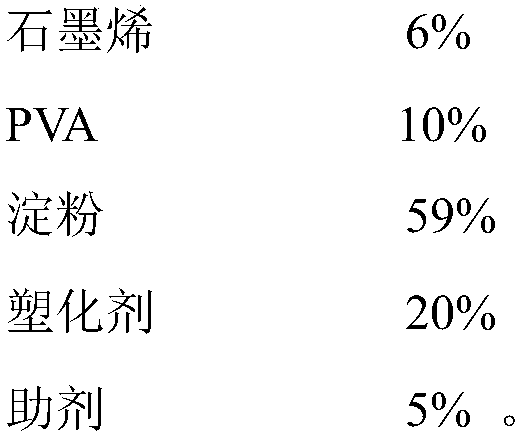

[0047] The weight percentage of used raw material is composed as follows:

[0048]

[0049] The graphene is a powder having a 3-layer benzene ring structure and a sheet diameter of 450 nm.

[0050] The degree of polymerization of the PVA is 3000, the degree of alcoholysis is 99.5%, and the particle size of the powder is 65 mesh.

[0051] The plasticizer is a mixture of polyethylene glycol, triacetin, 1,4-butanediol and deionized water, and the mixing mass ratio is 2:3:6:5.

[0052] The auxiliary agent is a mixture of lubricant, antioxidant and antiba...

Embodiment 3

[0058] The preparation method of the described graphene-modified PVA composite material is to use graphene as a modifying agent, carry out pre-plasticizing treatment with starch, PVA, plasticizer and auxiliary agent, and then carry out melting intercalation plasticizing extrusion, A graphene-modified PVA composite material is obtained; the temperature during the melting and intercalation plasticizing extrusion is 180±10° C.

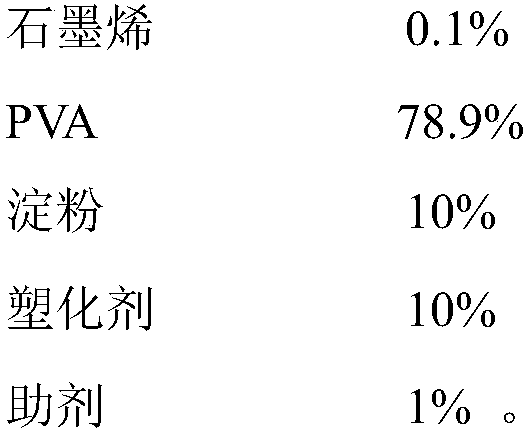

[0059] The weight percentage of used raw material is composed as follows:

[0060]

[0061] The graphene is an aqueous liquid having a 5-layer benzene ring structure and a sheet diameter of 300 nm.

[0062] The degree of polymerization of the PVA is 2000, the degree of alcoholysis is 82.5%, and the particle size of the powder is 60 mesh.

[0063] The plasticizer is a mixture of hexylene glycol, sodium alginate, ethylene diformamide, ethyl acetate and 1,4-butanediol, and the mixing mass ratio is 1:2:1:5:6.

[0064] The auxiliary agent is a mixture of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

| Powder particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com