Heat-resistant ceramic edible vessel capable of being burnt over open flame and production method thereof

A heat-resistant, ceramic technology that is applied in applications, household appliances, and other household appliances. It can solve the problems of limiting the scope of application and not being able to burn directly on an open flame, achieving good dispersion, shortening sintering time, and chemical stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A heat-resistant ceramic pot that can be burned on an open flame, the body of which includes the following mineral components by weight percentage: 35% kaolin, 32% spodumene, 9% lithium china stone, 7.5% carbon-free silicon whiskers, bentonite 5%, cooked talc 3.5% and clay 8%.

[0023] The kaolin contains Al by weight percentage 2 o 3 35% and SiO 2 52%.

[0024] The spodumene contains Li by weight percentage 2 O 6%, Al 2 o 3 22% and SiO 2 68%.

[0025] The lithium china stone contains Li by weight percentage 2 O 1.6%, Al 2 o 3 18% and SiO 2 70%.

[0026] Described carbon-free silicon whisker contains SiO by weight percentage 2 99.9%, its particle size is 25um, aspect ratio is 30.

[0027] Described bentonite contains SiO by weight percentage 2 73%, Al 2 o 3 16% and MgO 1.5%.

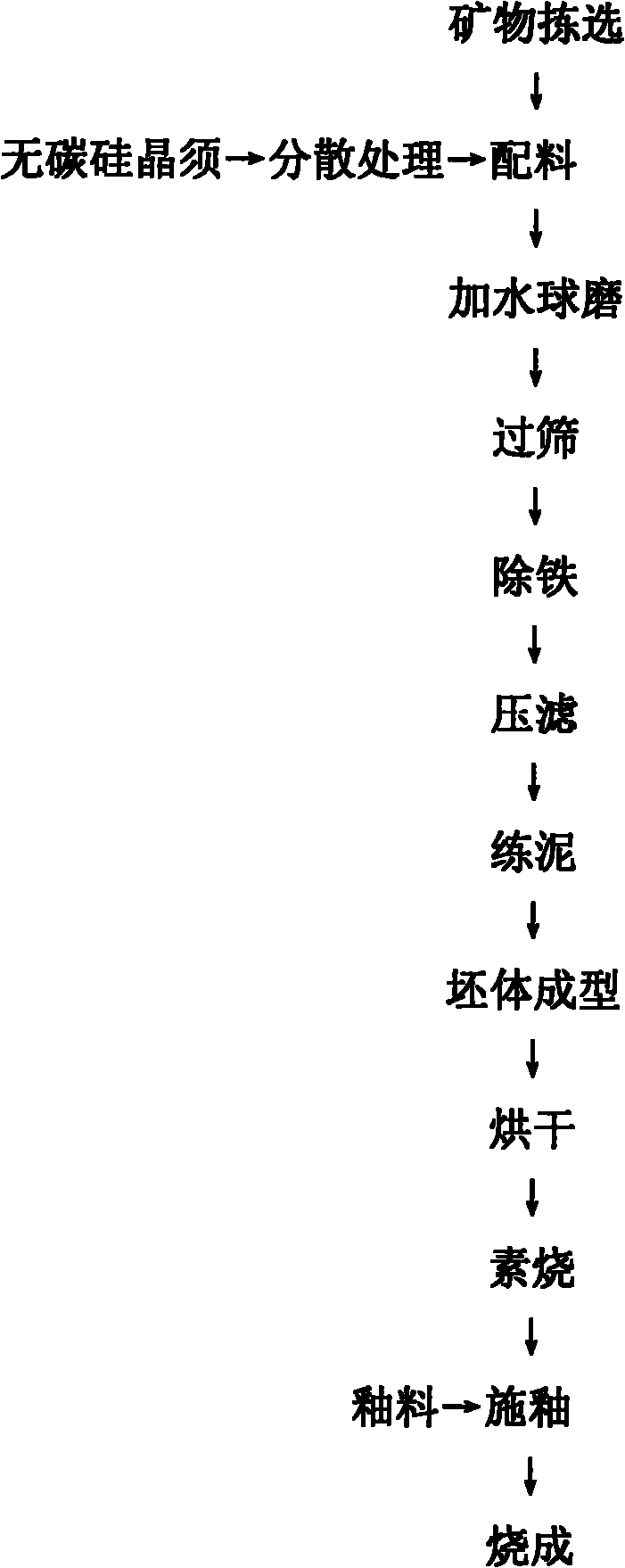

[0028] The production method of heat-resistant ceramic pot of the present invention comprises the following steps:

[0029] Adopt the method of mechanical low-speed bal...

Embodiment 2

[0034] A heat-resistant ceramic pot that can be burned on an open flame, the body of which includes the following mineral components by weight percentage: kaolin 40%, spodumene 26%, lithium china stone 8-10%, carbon-free silicon whisker 10% , bentonite 3%, cooked talc 5% and clay 6%.

[0035] The kaolin contains Al by weight percentage 2 o 3 36% and SiO 2 50%.

[0036] The spodumene contains Li by weight percentage 2 O 5%, Al 2 o 3 24% and SiO 2 65%.

[0037] The lithium china stone contains Li by weight percentage 2 O 2.2%, Al 2 o 3 20% and SiO 2 68%.

[0038] Described carbon-free silicon whisker contains SiO by weight percentage 2 99.5%, its particle size is 50um, aspect ratio is 20.

[0039] Described bentonite contains SiO by weight percentage 2 71%, Al 2 o 3 18% and MgO 1%.

[0040] The production method of heat-resistant ceramic kettle of the present invention comprises the following steps:

[0041] Adopt the method of mechanical low-speed ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com