A low-skin-effect large-diameter cable

A technology with skin effect and large wire diameter, which is applied in the power field, can solve the problems of high cable cost, poor corrosion resistance, high cost of use, etc., and achieves improved carrying capacity and operating efficiency, good heat resistance and heat dissipation performance, and over-current The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

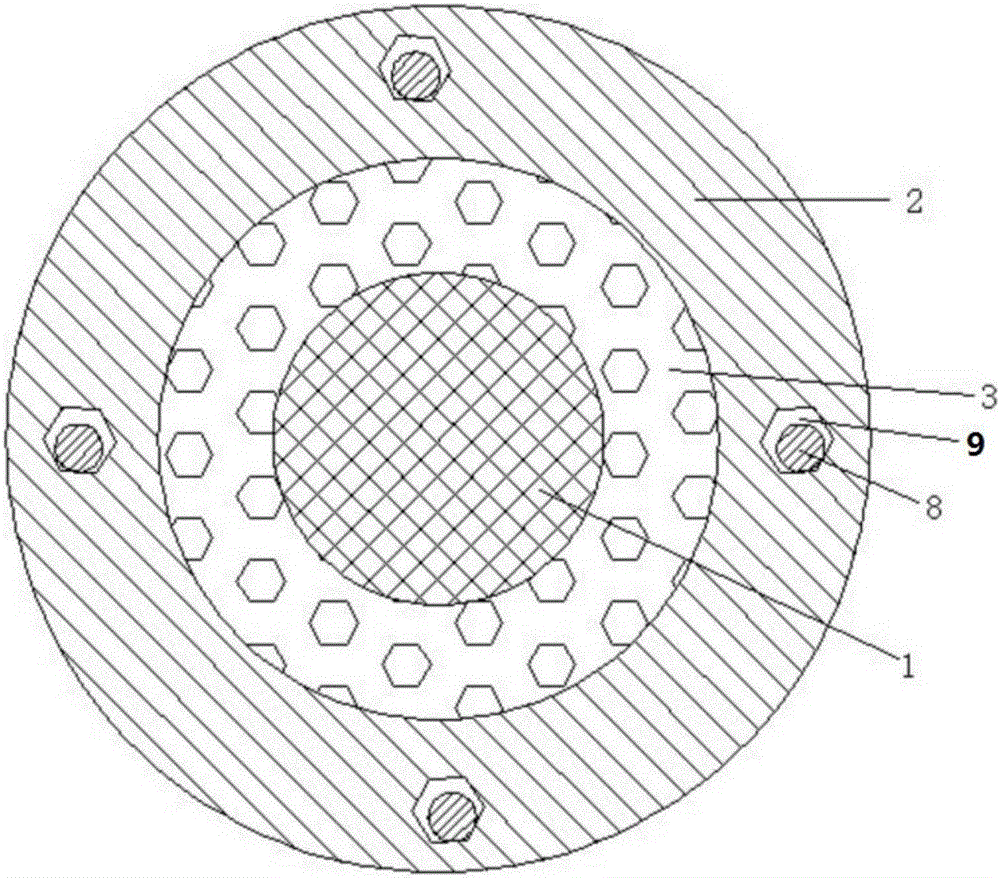

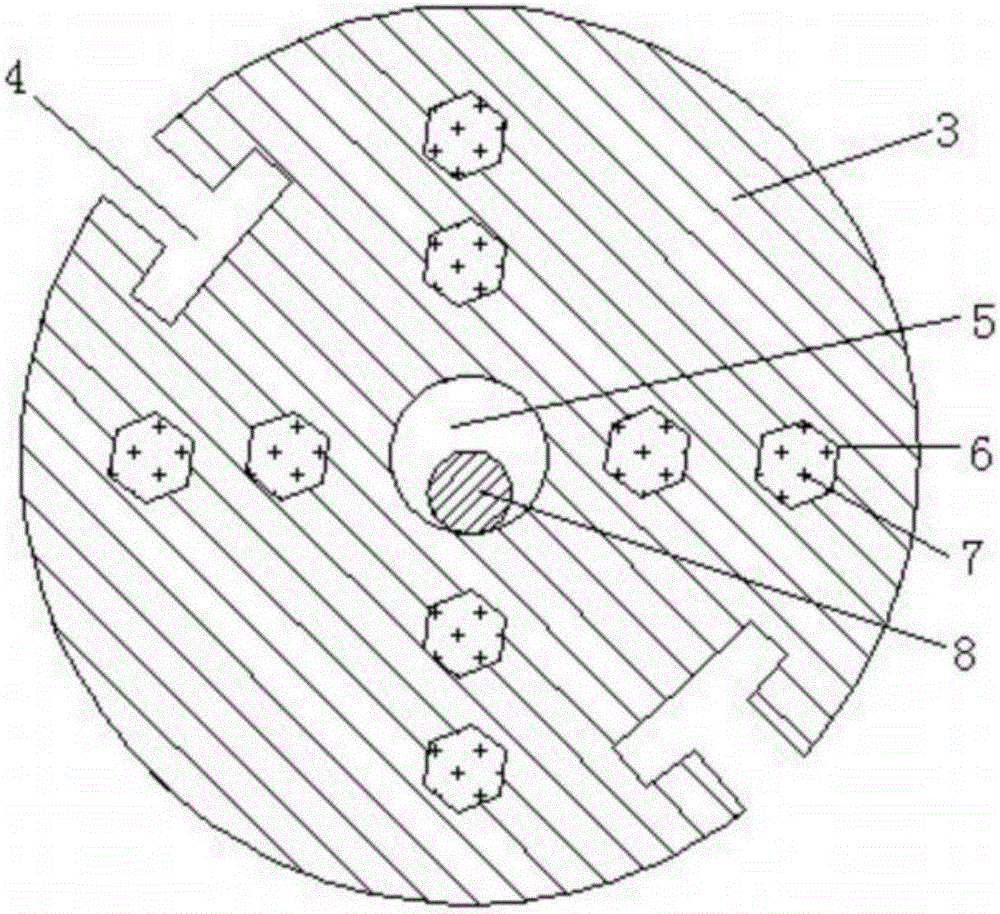

[0013] like figure 1 and 2 The low-skin effect large-diameter cable is composed of a cable core 1 and an insulating layer 2, the insulating layer 2 is coated on the outer surface of the cable core 1, and an elastic buffer layer is additionally provided between the insulating layer 2 and the cable core 1 3. The outer surface of the cable core 1 is evenly distributed with "T"-shaped heat dissipation grooves 4, and the inner center is provided with a reinforcement hole 5 with a circular cross section, and with the center of the reinforcement hole 5 as the center, at least two layers of the first heat sink are distributed in a ring shape. Load holes 6, 4 in each layer, insulating ceramic powder 7 is set in the first load drop hole 6, elastic tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com