Nano-structure coating with ultra-high hardness and manufacturing method thereof

A nanostructure and hardness technology, applied in the field of materials science, can solve the problems of coating hardness, high temperature oxidation resistance that cannot meet high-speed cutting and dry cutting, coating performance, deposition conditions and deposition efficiency, etc., to achieve excellent High temperature oxidation resistance, excellent mechanical properties, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation, characterization and measuring instruments used in the present invention:

[0030] JGP-450 Magnetron Sputtering System, Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences

[0031] D8Advance X-ray diffractometer, Bruker, Germany

[0032] NANOIndenterG200 nanoindenter, Agilent Technologies, USA

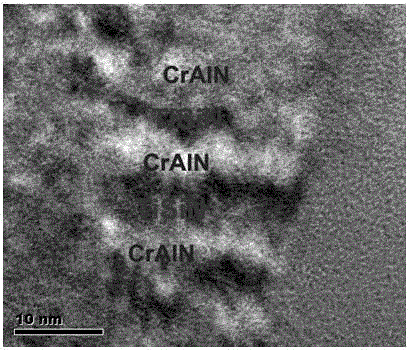

[0033] TecnaiG 2 Model 20 high-resolution transmission electron microscope, FEI, USA

[0034] QuantaFEG450 scanning electron microscope, American FEI company

Embodiment 1

[0036] A method for preparing a nanostructured coating with ultrahigh hardness, comprising the steps of:

[0037] 1) A step for cleaning the substrate:

[0038] First, send the polished substrate into an ultrasonic cleaning machine, and use 15-30kHz ultrasonic waves to clean it in absolute alcohol and acetone for 5-10 minutes; then perform ion cleaning, that is, put the substrate into a vacuum chamber and vacuumize it to 6×10 -4 Ar gas is introduced after the Pa, and the vacuum degree is maintained at 2-4 Pa. The substrate is ion-bombarded with radio frequency (13.56MHz) for 20-50 minutes, and the power is 80-100W; the substrate is ceramic.

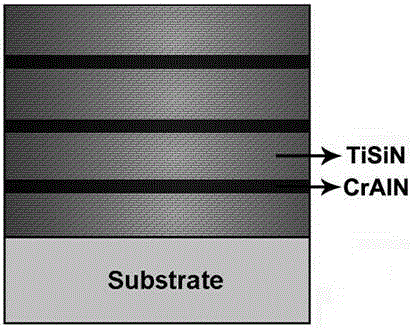

[0039] 2) a step of alternately sputtering TiSiN layers and CrAlN layers;

[0040] TiSi (84atom%:16atom%) composite target and CrAl target (50atom%:50atom%) are used, with a diameter of 75mm; Ar gas flow: 40sccm, N 2 Air flow: 5sccm;

[0041] TiSiN layer sputtering power 350W, time 20s; CrAl layer sputtering power 150W, time 3s;

[0...

Embodiment 2

[0045] A method for preparing a nanostructured coating with ultrahigh hardness, comprising the steps of:

[0046] 1) A step for cleaning the substrate:

[0047] First, send the polished substrate into an ultrasonic cleaning machine, and use 15-30kHz ultrasonic waves to clean it in absolute alcohol and acetone for 5-10 minutes; then perform ion cleaning, that is, put the substrate into a vacuum chamber and vacuumize it to 6×10 -4 Ar gas is introduced after the Pa, and the vacuum degree is maintained at 2-4Pa. The substrate is bombarded with ions for 20-50min by radio frequency (13.56MHz), and the power is 80-100W; the substrate is nickel-chromium alloy.

[0048] 2) a step of alternately sputtering TiSiN layers and CrAlN layers;

[0049] TiSi (84atom%:16atom%) composite target and CrAl target (50atom%:50atom%) are used, with a diameter of 75mm; Ar gas flow: 20sccm, N 2 Air flow: 2sccm;

[0050] TiSiN layer sputtering power 350W, time 20s; CrAl layer sputtering power 150W, ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com