Self-crosslinking styrene-acrylic emulsion for non-woven fabrics and preparation method of self-crosslinking styrene-acrylic emulsion

A styrene-acrylic emulsion and self-crosslinking technology, used in textiles, papermaking, fiber processing, etc., can solve problems such as high prices, and achieve the effects of easy control, easy polymerization system, and high resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

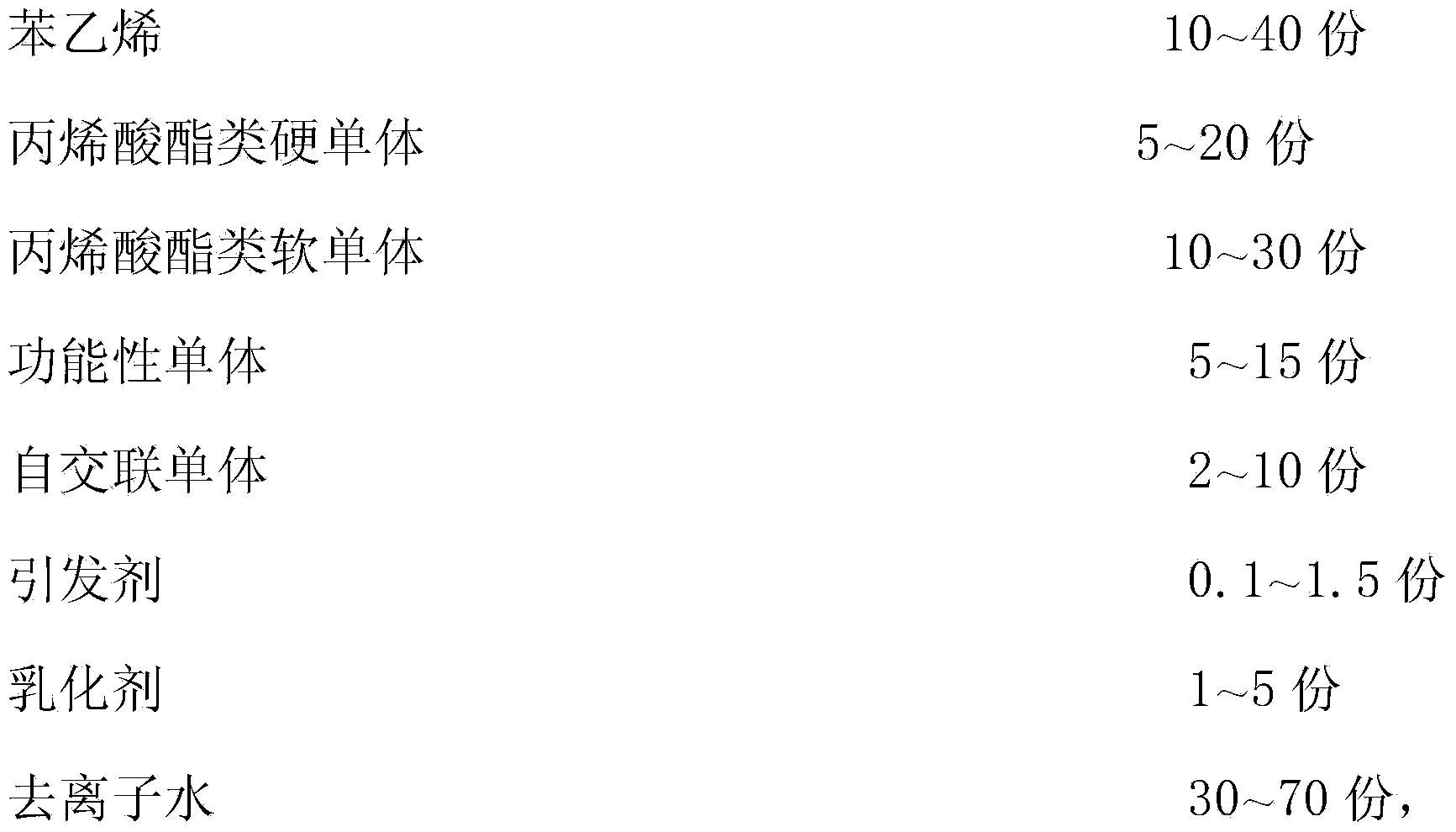

[0024] A kind of raw material formula of self-crosslinking styrene-acrylic emulsion for non-woven fabric is as follows:

[0025]

[0026] Wherein, the emulsion polymerization process is as follows:

[0027] (1) First, completely dissolve 1 / 4 of the emulsifier with 1 / 3 deionized water, then add the mixed monomers in turn, and stir thoroughly to obtain a pre-emulsion.

[0028] (2) Completely dissolve the initiator with 1 / 7 of deionized water to obtain an aqueous solution of the initiator.

[0029] (3) Add the remaining deionized water, the remaining emulsifier, and 1 / 4 of the initiator aqueous solution to the reaction equipment and fully stir and disperse, then raise the temperature to 80°C, then add 10% pre-emulsion, and react for 30 minutes to form a seed emulsion, then Start to drop the remaining pre-emulsion and the remaining initiator aqueous solution at a constant speed at the same time, and control the dripping for 3 hours; after the dropping is completed, raise the t...

Embodiment 2

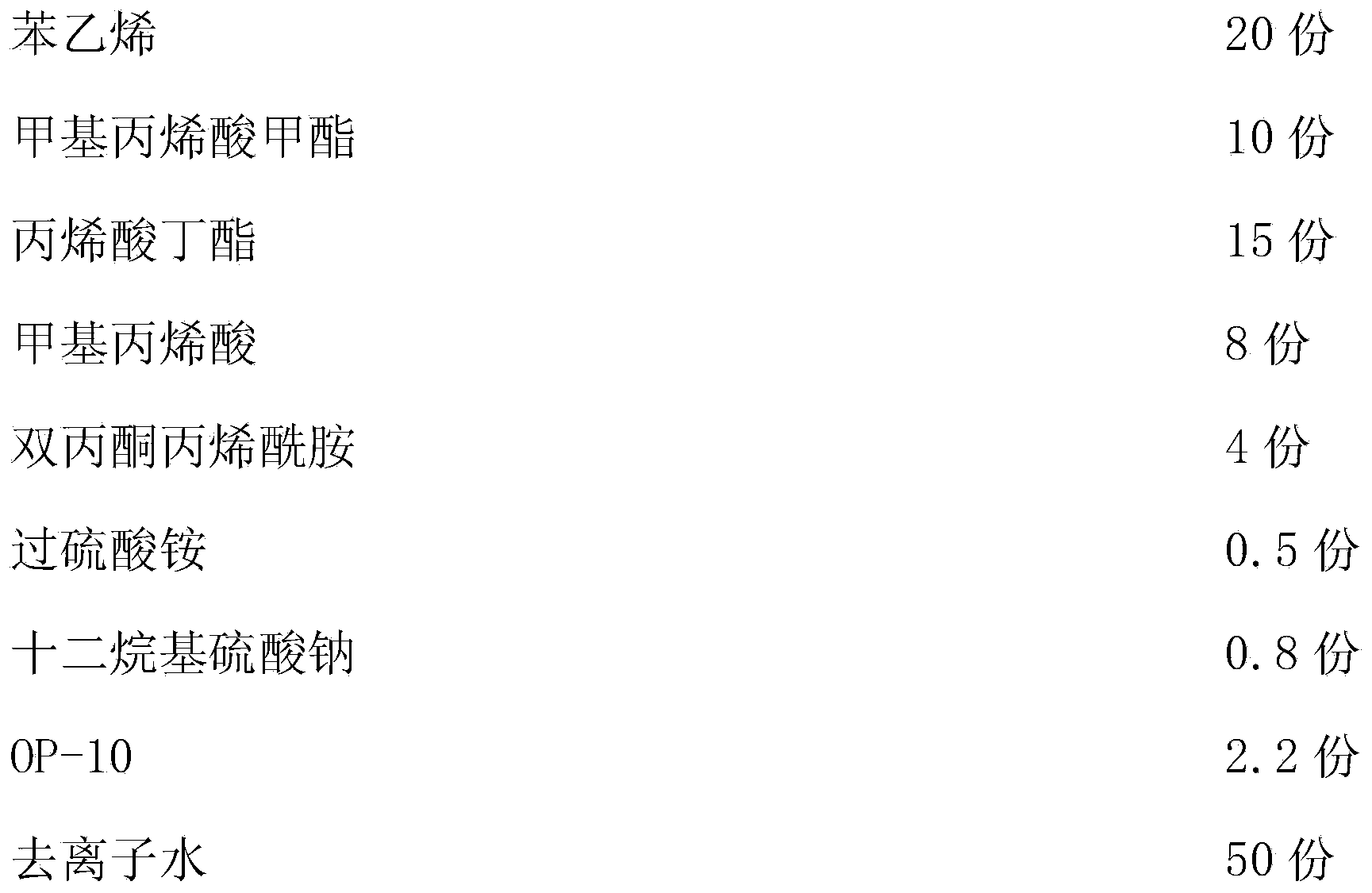

[0031] A kind of raw material formula of self-crosslinking styrene-acrylic emulsion for non-woven fabric is as follows:

[0032]

[0033] Wherein, the emulsion polymerization process is as follows:

[0034] (1) First, completely dissolve 1 / 4 of the emulsifier with 1 / 3 deionized water, then add the mixed monomers in turn, and stir thoroughly to obtain a pre-emulsion.

[0035] (2) Completely dissolve the initiator with 1 / 7 of deionized water to obtain an aqueous solution of the initiator.

[0036] (3) Add the remaining deionized water, the remaining emulsifier, and 1 / 4 of the initiator aqueous solution to the reaction equipment and fully stir and disperse, then raise the temperature to 80°C, then add 10% pre-emulsion, and react for 30 minutes to form a seed emulsion, then Start to drop the remaining pre-emulsion and the remaining initiator aqueous solution at a constant speed at the same time, and control the dripping for 3 hours; after the dropping is completed, raise the t...

Embodiment 3

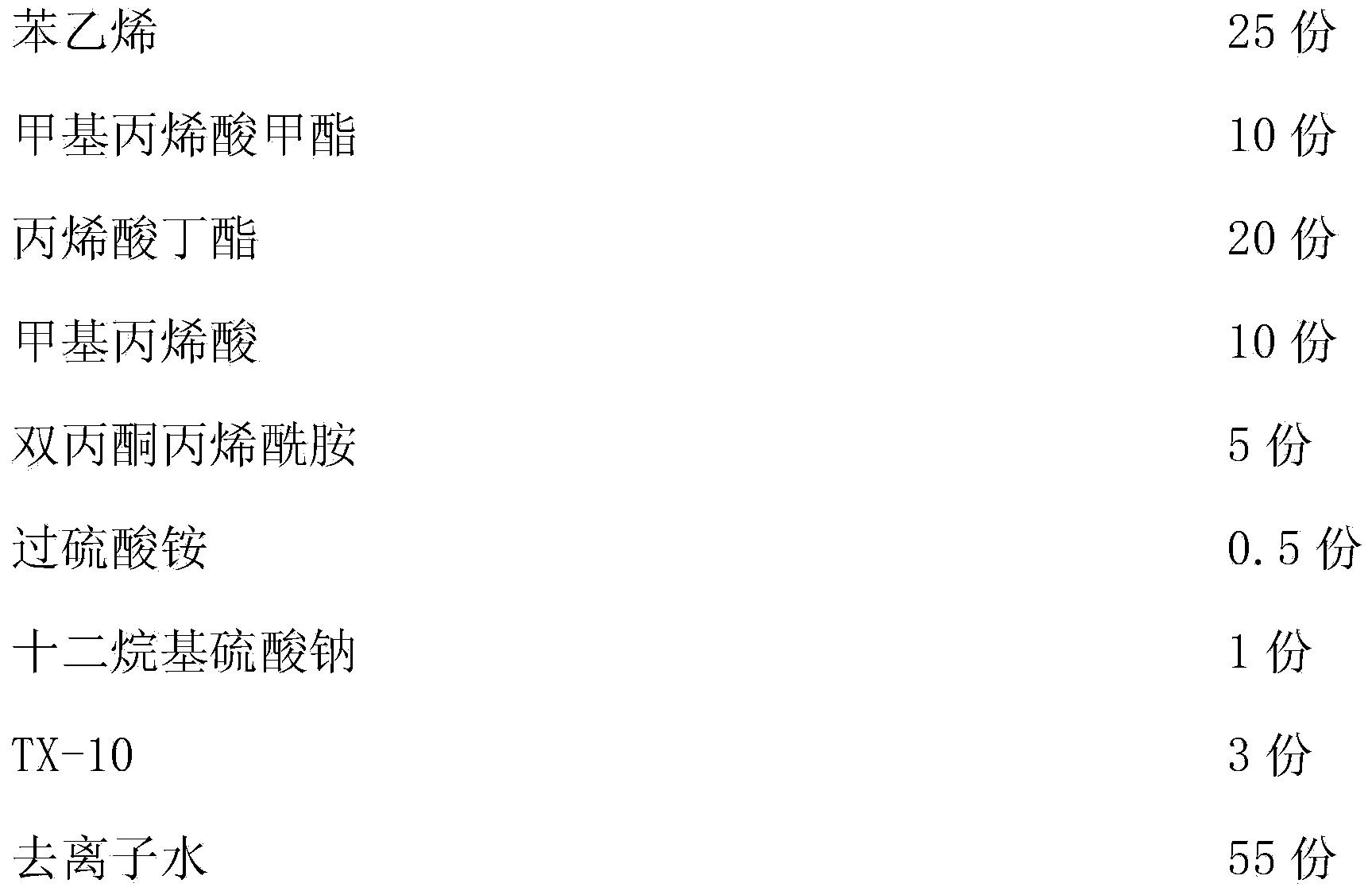

[0038] A kind of raw material formula of self-crosslinking styrene-acrylic emulsion for non-woven fabric is as follows:

[0039]

[0040]

[0041] Wherein, the emulsion polymerization process is as follows:

[0042] (1) First, completely dissolve 1 / 4 emulsifier with 1 / 3 deionized water, then add mixed monomers in turn, and stir thoroughly to obtain a pre-emulsion.

[0043] (2) Completely dissolve the initiator with 1 / 8 deionized water to obtain an aqueous solution of the initiator.

[0044] (3) Add the remaining deionized water, remaining emulsifier, and 1 / 5 initiator aqueous solution to the reaction equipment and fully stir and disperse, then raise the temperature to 75°C, then add 5% pre-emulsion, react for 15 minutes to form a seed emulsion, and then start At the same time, slowly drop in the remaining pre-emulsion and the remaining initiator aqueous solution at a uniform speed, and control the dripping for 2 hours; after the dropping is completed, raise the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com