Hyperbranched ionic liquid as well as preparation method and application

A technology of ionic liquids and hyperbranched polymers, applied in the field of hyperbranched polymers, can solve the problems of high water-resistant glass transition temperature, low curing volume shrinkage, and high curing temperature, so as to improve reactivity and compatibility, reduce The effects of curing temperature and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

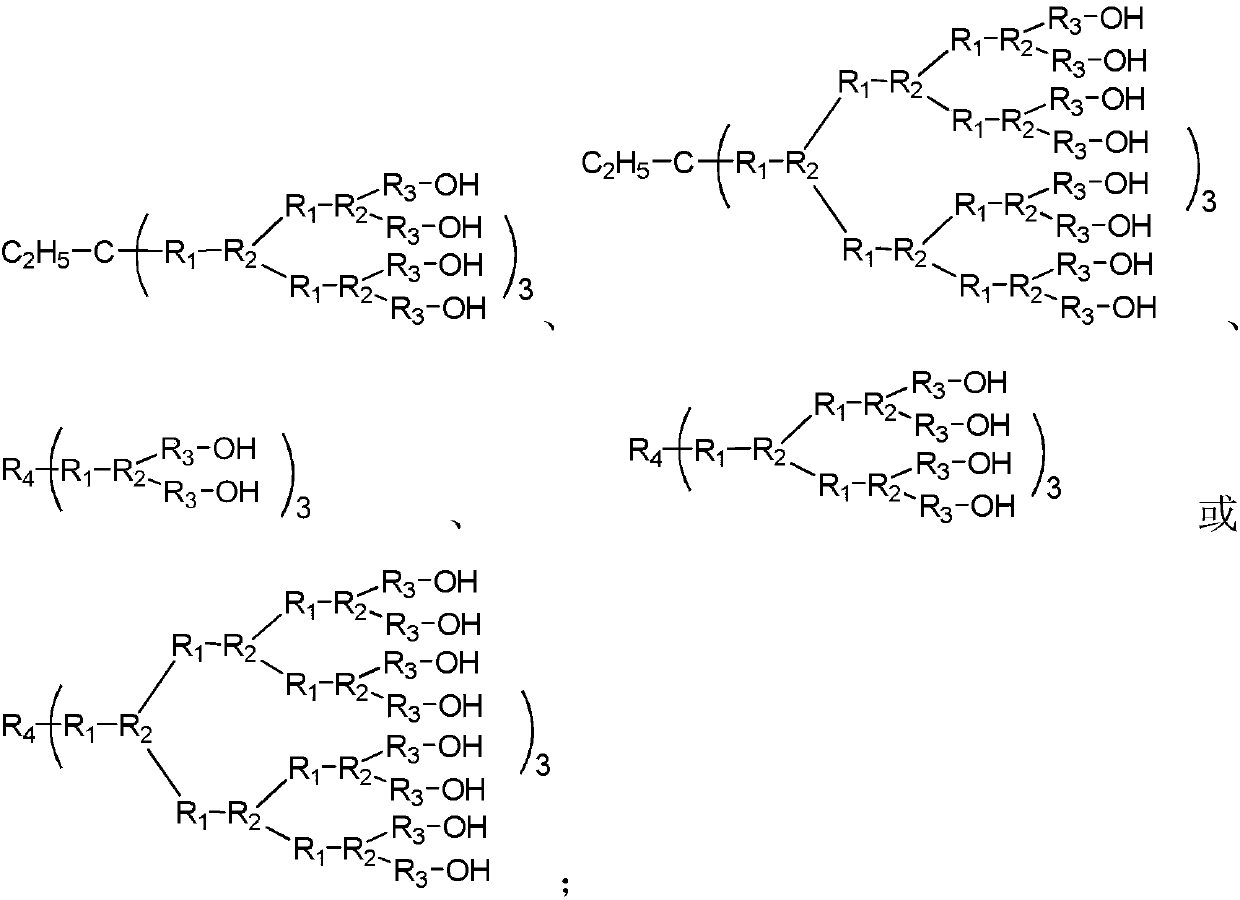

Method used

Image

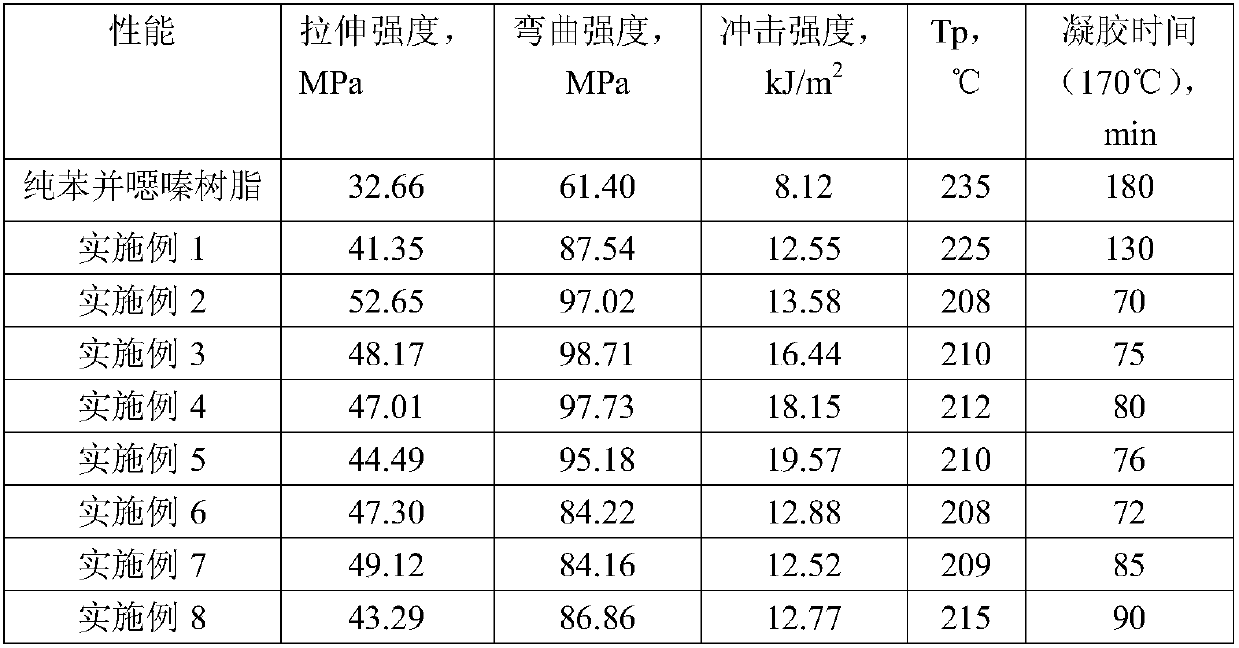

Examples

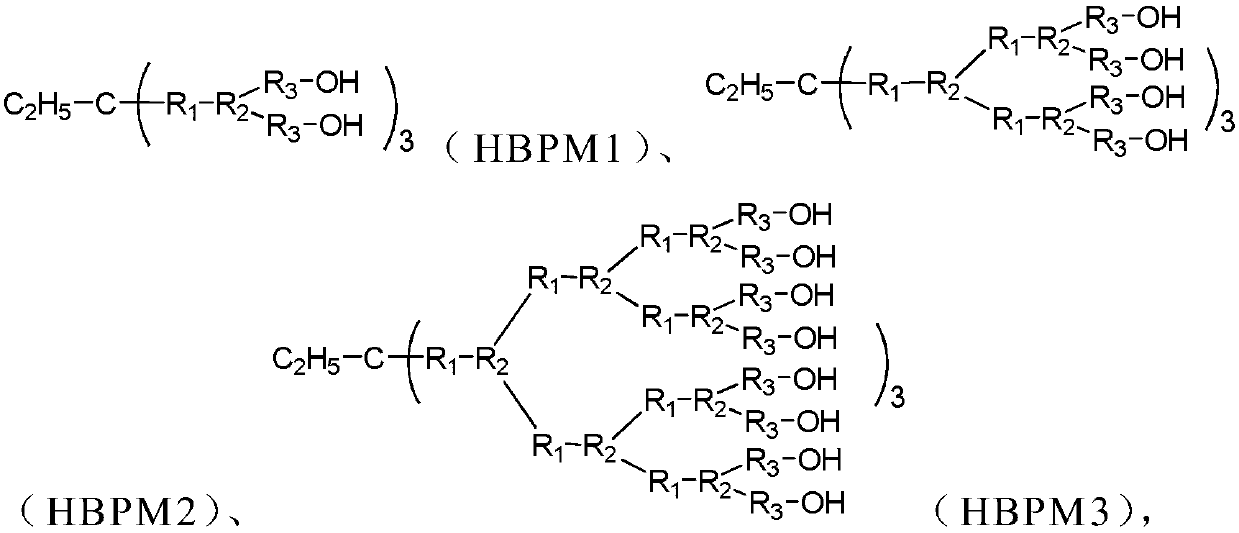

Embodiment 1

[0033] (a) Mix 13.42g of trimethylolpropane, 40.24g of dimethylolpropionic acid and 0.27g of p-toluenesulfonic acid, and stir and react at 170°C for 6h to obtain the first-generation hydroxyl-terminated hyperbranched polyester HBPM- 1. Each mole of HBPM-1 contains 6 moles of hydroxyl groups, and the number average molecular weight is 500 g / mol.

[0034] (b) Mix 48.26g HBPM-1, 76.42g mercaptopropionic acid MPA, 120mL dioxane and 2.49g p-toluenesulfonic acid, stir and react at 80°C for 12h, then wash with 150ml saturated aqueous sodium bicarbonate solution three times To neutrality, the organic layer was dried with anhydrous magnesium sulfate, filtered, and the organic solvent was distilled off under reduced pressure to obtain the first-generation mercapto-terminated hyperbranched polyester THBPM-1, with a number average molecular weight of 1100 g / mol.

[0035] (c) After mixing 50.57g THBPM-1, 80.44g 1-allyl-3-methylimidazolium hexafluorophosphate AMIMPF6 and 2.62g photoinitiato...

Embodiment 2

[0037] (a) Mix 13.42g trimethylolpropane, 120.72g dimethylolpropionic acid and 0.67g p-toluenesulfonic acid evenly, and carry out stirring reaction at 180°C for 5h to obtain the second generation hydroxyl-terminated hyperbranched polyester HBPM- 2. Each mole of HBPM-2 contains 12 moles of hydroxyl groups, and the number average molecular weight is 1100 g / mol.

[0038] (b) Mix 117.93g HBPM-2, 152.84g mercaptopropionic acid MPA, 250mL dioxane and 5.42g p-toluenesulfonic acid, stir and react at 90°C for 10h, then wash with 150ml saturated aqueous sodium bicarbonate solution three times To neutrality, the organic layer was dried with anhydrous magnesium sulfate, filtered, and the organic solvent was distilled off under reduced pressure to obtain the second-generation mercapto-terminated hyperbranched polyester THBPM-2, with a number average molecular weight of 2200 g / mol.

[0039](c) After mixing 55.93g THBPM-2, 80.44g 1-allyl-3-methylimidazolium hexafluorophosphate AMIMPF6 and 2....

Embodiment 3

[0041] (a) Mix 13.42g trimethylolpropane, 120.72g dimethylol propionic acid and 0.67g p-toluenesulfonic acid evenly, and carry out stirring reaction at 190°C for 4h to obtain the second generation hydroxyl-terminated hyperbranched polyester HBPM- 2. Each mole of HBPM-2 contains 12 moles of hydroxyl groups, and the number average molecular weight is 1100 g / mol.

[0042] (b) Mix 117.93g HBPM-2, 152.84g mercaptopropionic acid MPA, 250mL dioxane and 5.42g p-toluenesulfonic acid, stir and react at 100°C for 8h, then wash with 150ml saturated aqueous sodium bicarbonate solution three times To neutrality, the organic layer was dried with anhydrous magnesium sulfate, filtered, and the organic solvent was distilled off under reduced pressure to obtain the second-generation mercapto-terminated hyperbranched polyester THBPM-2, with a number average molecular weight of 2200 g / mol.

[0043] (c) After mixing 55.93g THBPM-2, 93.07g 1-allyl-3-butylimidazole hexafluorophosphate ABIMPF6 and 2.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com