Silicon and phosphorus modified ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve problems such as unfavorable shape-selective reaction, and achieve excellent selectivity and good activity stability , the effect of improving the reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

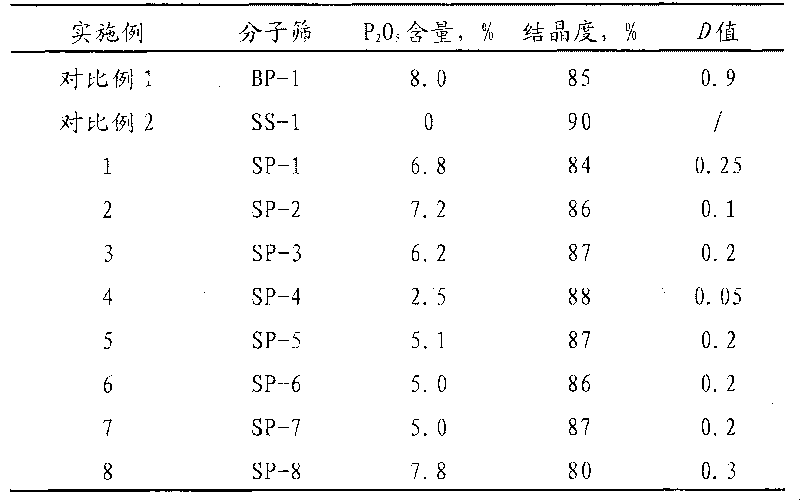

[0038] Weigh 10 grams of BP-1 molecular sieves, mix it with 5.36g ethyl orthosilicate (Beijing Chemical Reagent Company, analytically pure, SiO 2 Content 28%), 3.33g tetrapropylammonium bromide (Guangzhou Dayou fine chemical factory production, analytical purity, 99%) 12ml aqueous solution is mixed, it is placed in the crystallization kettle that contains polytetrafluoroethylene liner, at 150 After static crystallization at ℃ for 20 hours, cool to room temperature. Afterwards, the molecular sieve was dried at 120℃ for 4 hours and calcined at 550℃ for 3 hours to obtain the modified molecular sieve SP-1. The phosphorus content, crystallinity and D value of SP-1 are listed in Table 1.

Embodiment 2

[0040] Take by weighing 10 grams of BP-1 molecular sieves, mix it with 2.53g methyl orthosilicate (Beijing Chemical Reagent Company, analytically pure, 99%), 8.17g tetraethylammonium hydroxide (produced by Guangzhou Dayou Fine Chemical Factory, Tetraethylammonium hydroxide 27% by weight, water 73% by weight) are mixed, it is placed in the crystallization kettle that contains polytetrafluoroethylene liner, is cooled to room temperature after static crystallization at 180 ℃ for 20 hours, afterwards, molecular sieve is in 120 ℃ drying for 4 hours, 550 ℃ calcination for 3 hours to obtain the modified molecular sieve SP-2, the phosphorus content, crystallinity and D value of SP-2 are listed in Table 1.

Embodiment 3

[0042] Take by weighing 10 gram HZSM-5 (2) molecular sieves, it is impregnated in 12ml, in the aqueous solution containing 0.93 gram ammonium dihydrogen phosphate (Beijing Yili Fine Chemicals Co., Ltd., analytically pure, 99%), normal temperature immersion 8 hours, After drying at 120°C and calcining at 550°C for 3 hours, phosphorus-loaded ZSM-5 was obtained.

[0043] Get 10 grams of the above-mentioned molecular sieves loaded with phosphorus, and mix it with 1.428g ethyl orthosilicate (Beijing Chemical Reagent Company, analytically pure, SiO 2 content 28%), 1.815g tetraethylammonium hydroxide (Guangzhou Dayou fine chemical factory production, tetraethylammonium hydroxide 27% by weight, water 73% by weight), 4.42g n-hexane (Beijing Chemical Plant, analytically pure, 95%) were mixed, placed in a crystallization kettle with a polytetrafluoroethylene liner, and cooled to room temperature after static crystallization at 170°C for 20 hours. After that, the molecular sieves were dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com