A kind of positive electrode material for zinc-bromine flow battery and its preparation and application

A zinc-bromine flow battery, cathode technology, applied in battery electrodes, regenerative fuel cells, circuits, etc., can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

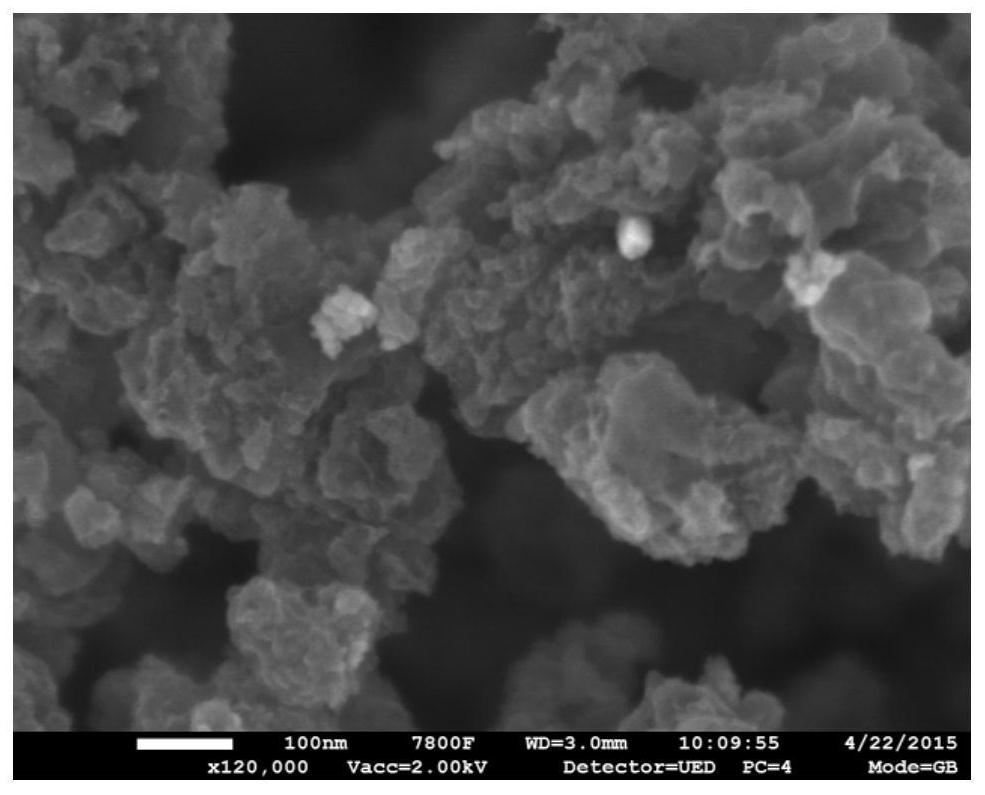

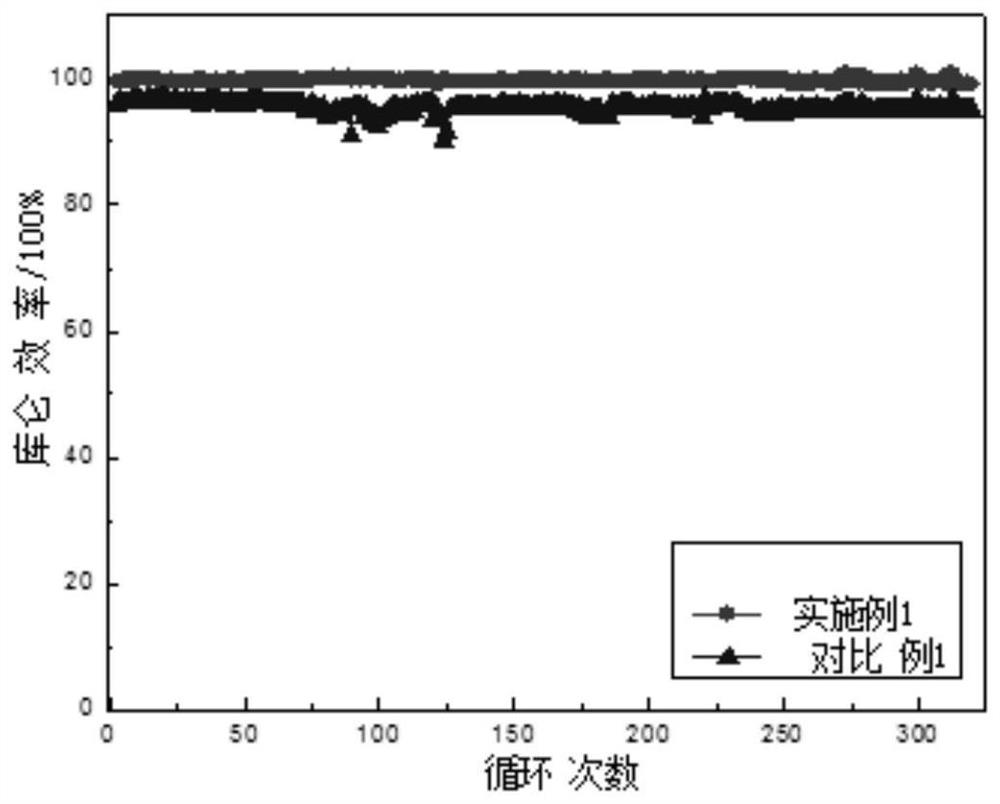

[0030] 2 g of titanium dimethyl dithiocarbamate was placed under nitrogen, and the temperature was increased from room temperature to a sintering temperature of 500 degrees Celsius at a heating rate of 1 degree Celsius per minute. After sintering at 500 degrees Celsius for 1 h, the carbon-coated titanium sulfide was taken out. The material is agglomerated in granular form see figure 1 , the white particles are uncoated titanium sulfide. The prepared carbon-coated titanium disulfide material and the binder nafion were coated on 36cm in a ratio of 9:1. 2 On carbon felt (5mm thickness), the load is 2mg / cm 2 , as the positive electrode;

[0031] The negative electrode is 36cm 2 Carbon felt (5mm thickness) with nafion membrane as the diaphragm. Both positive and negative electrolytes were 60 ml of 2 mol / L zinc bromide solution. Through the circulation pipeline, it circulates between the liquid storage tank and the positive and negative electrodes of the battery. The battery ...

Embodiment 2

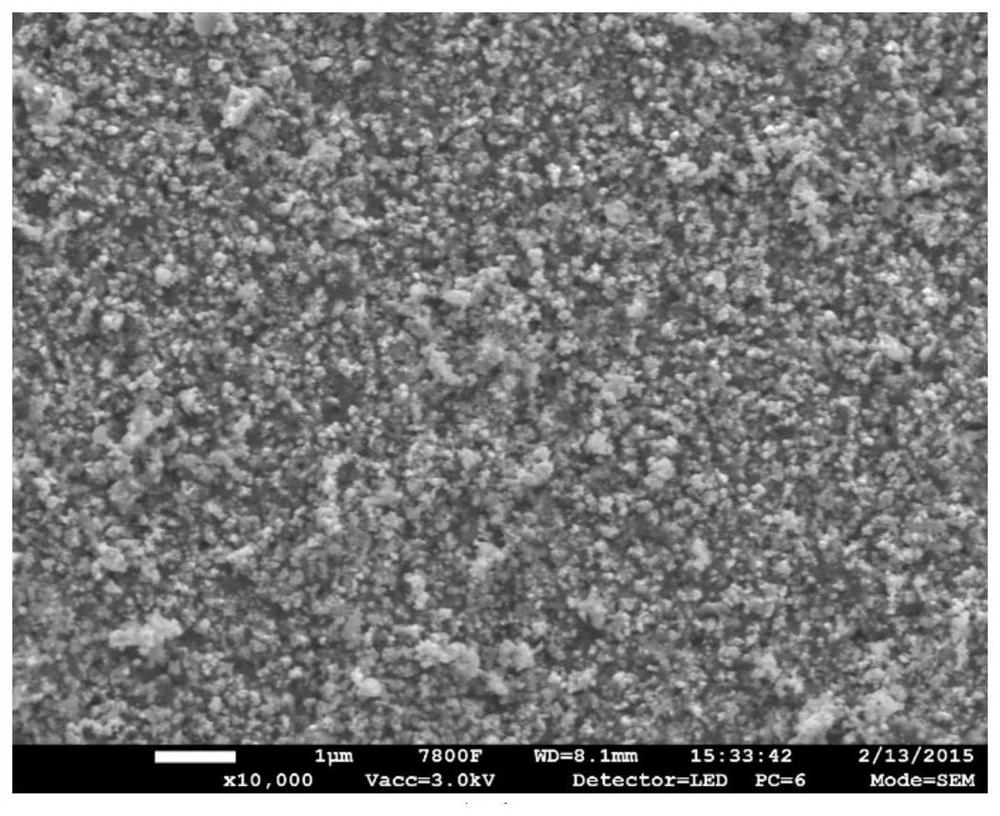

[0036] 2 g of titanium diethyldithiocarbamate was placed under nitrogen to heat up from room temperature to a sintering temperature of 700 degrees Celsius, and the heating rate was 10 degrees Celsius / min. After sintering at 700 degrees Celsius for 2 hours, the carbon-coated titanium sulfide was taken out. Material is agglomerated in granular form, see Figure 4 .

Embodiment 3

[0038] 2 g of titanium diethyldithiocarbamate was placed under nitrogen to heat up from room temperature to a sintering temperature of 1000 degrees Celsius, and the heating rate was 5 degrees Celsius / min. After sintering at 1000 degrees Celsius for 4 hours, the carbon-coated titanium sulfide was obtained. The material is agglomerated in granular form see Figure 5 , it can be clearly seen from the figure that the bright white is titanium sulfide, and the titanium sulfide is embedded in the carbon skeleton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com