Method for preparing metallic titanium through vulcanization and electrolysis of titanium and iron composite ore and carbon

A technology of metal titanium and titanium sulfide, applied in the direction of electrolysis components, electrolysis process, metal material coating process, etc., can solve the problems of excessive carbon content of carbon products, excessive carbon, high cost, etc., achieve high electrolysis efficiency, less intermediate products, The effect of efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

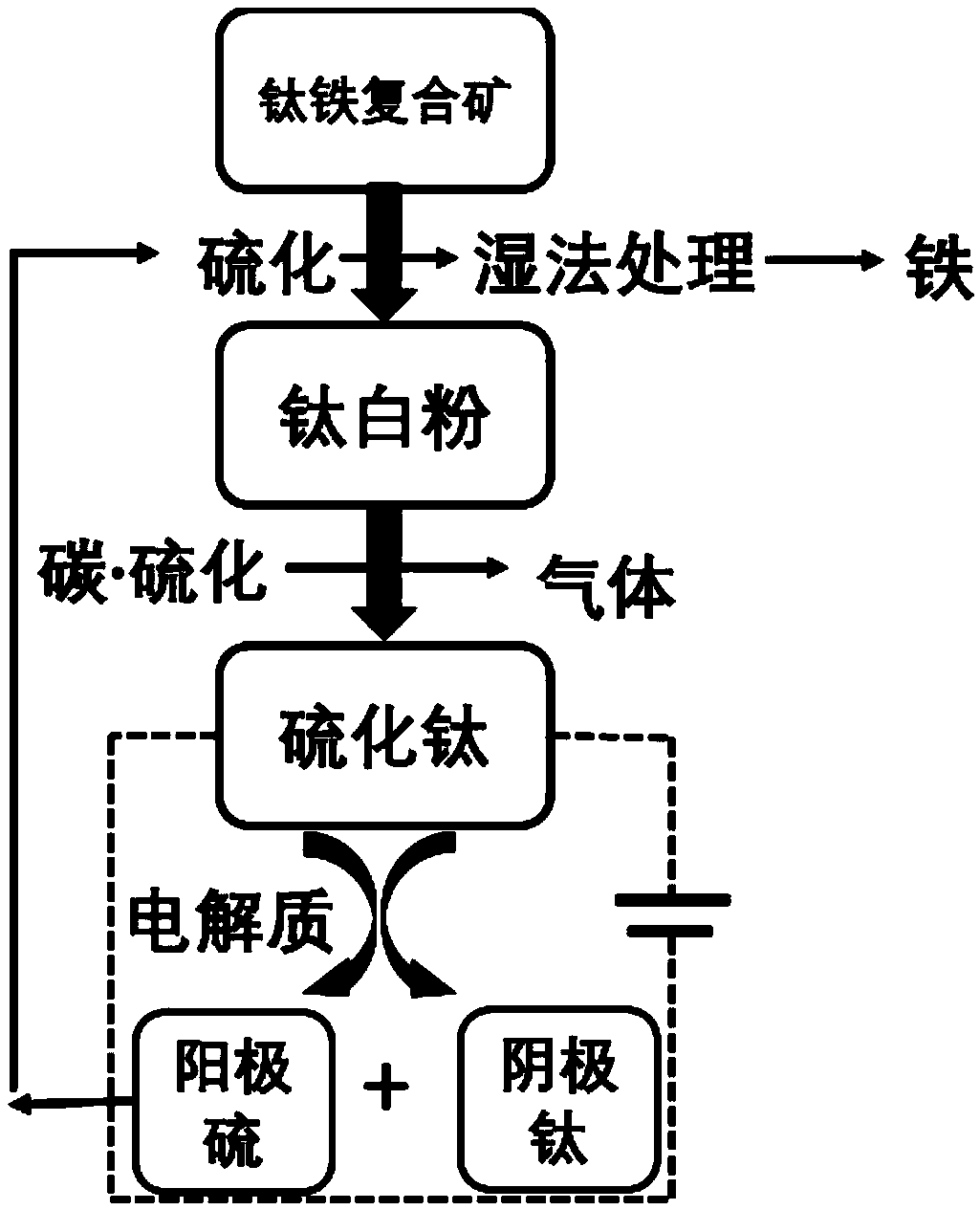

[0043] (1) Low-cost preparation and synthesis of titanium sulfide (TiS) with metal conductivity 2 , TiS, Ti 2 S, Ti 3 S, Ti 6 S and Ti 4 S 5 wait);

[0044] (2) The titanium sulfide can be prepared by processing titanium-containing concentrates, which effectively solves the problem of stacking and discarding titanium-containing ores such as vanadium-titanium magnetite;

[0045] (3) Titanium sulfide is used as a soluble anode. During the electrolysis process, titanium is dissolved in the electrolyte in the form of ions, and sulfur is discharged from the anode in the form of sulfur gas for recycling, effectively realizing the efficient and comprehensive utilization of resources and energy;

[0046] (4) Due to the weak affinity between titanium and sulfur, metal titanium can be obtained at a high rate without re-contamination;

[0047] (5) Direct electrolysis in the electrolyte can deposit metal titanium with low oxygen content at the cathode.

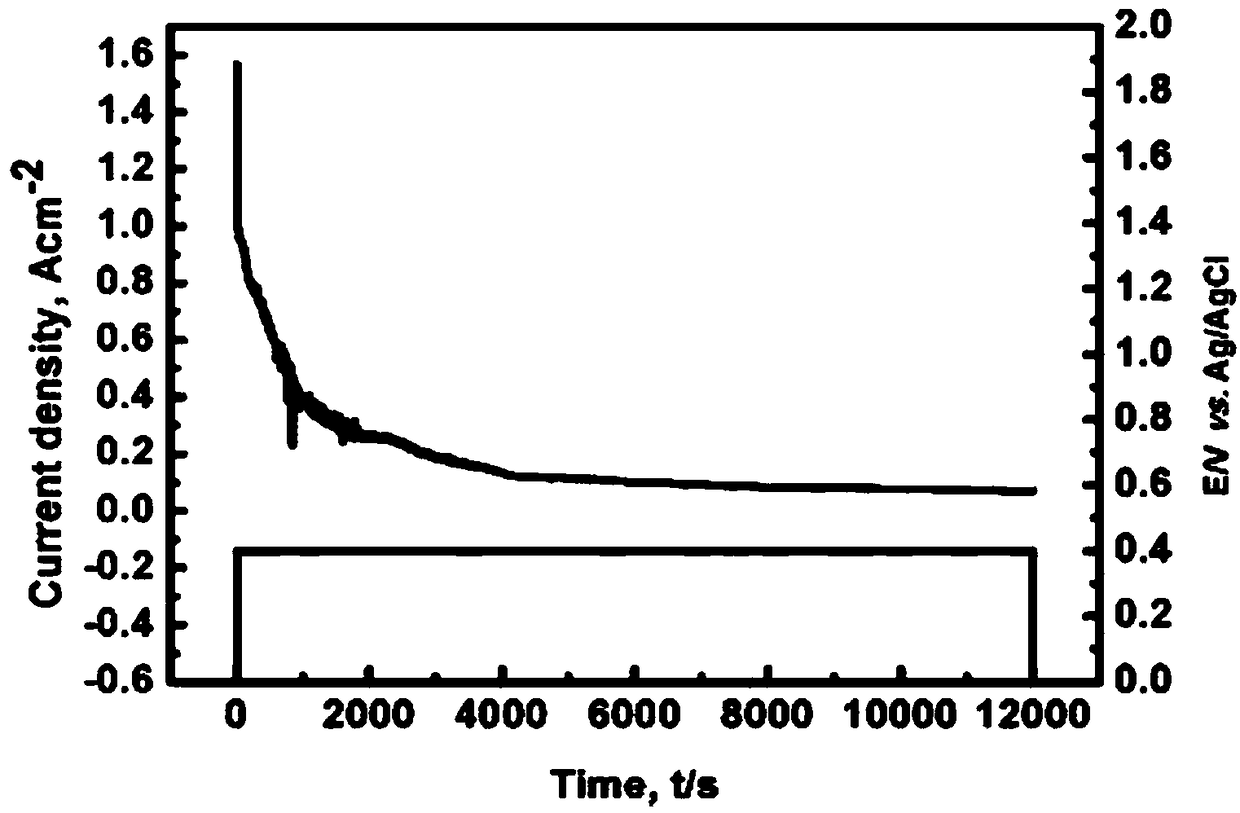

[0048] In S2, the cathode i...

specific Embodiment 1

[0051] Titanium dioxide (TiO 2 , 99.5wt%), graphite powder (99.95), sulfur powder (99%) were prepared according to the molar ratio of 1:2:2.1, a total of 100g.

[0052] Mix and grind in a spherical ball mill for 12 hours, weigh 5g and press it into a small piece with a diameter of 5mm*5mm under a pressure of 10Mpa, and place it in a closed glass tube at one end, and seal it with high-temperature resistant organic glue to ensure that the glass tube No air leakage at high temperature.

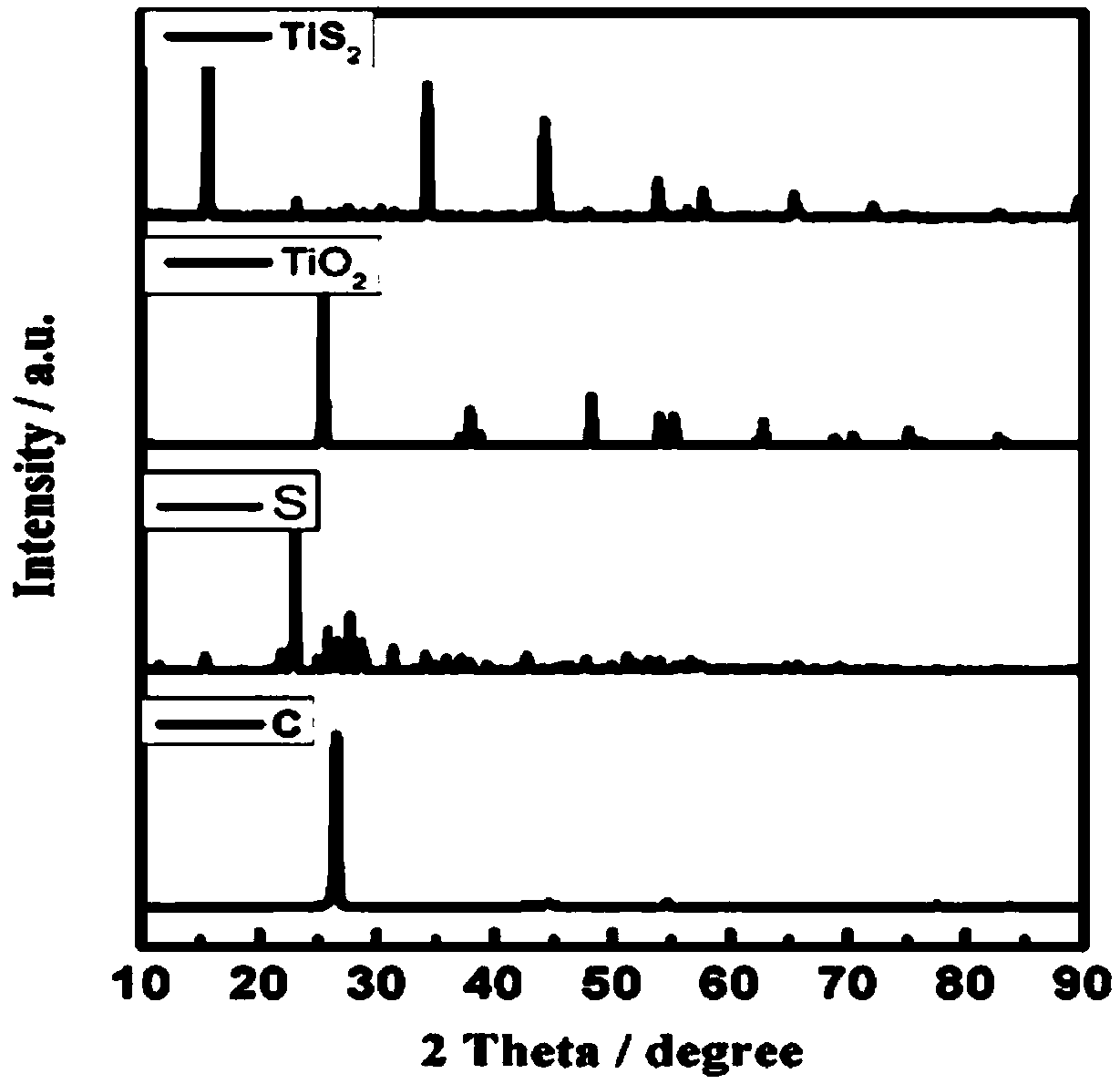

[0053] Then place the glass tube in a muffle furnace, burn it at 1000 °C for 10 h, then lower the temperature to room temperature, cut the glass tube and take out the synthesized TiS 2 Material. Synthesized TiS 2 The XRD diffraction pattern of the material is attached figure 2 shown.

[0054] Then use vacuum high temperature (1100°C) to treat TiS 2 The material is sintered to obtain a cylindrical anode with a diameter of 10mm*15mm.

specific Embodiment 2

[0057] For 500g of titanium concentrate FeTiO 3 Sulfurization treatment is carried out at 1200°C, and the processed products are FeS and TiO 2 Mix powder.

[0058] The mixed powder was soaked in 1mol / L dilute hydrochloric acid, vacuum filtered, and then dried in an oven at 80°C to obtain titanium dioxide (TiO 2 ).

[0059] Titanium dioxide (TiO 2 , 99.5wt%), graphite powder (99.95), sulfur powder (99%) were prepared according to the molar ratio of 1:2:2.2, a total of 10g.

[0060] Mix and grind in a spherical ball mill for 12 hours, weigh 2 g and press it into a small piece with a diameter of 5mm*5mm under a pressure of 10Mpa, and place it in a closed glass tube at one end, and seal it with high-temperature resistant organic glue to ensure that the glass tube In a sealed state, there is no air leakage under high temperature.

[0061] Then place the glass tube in a muffle furnace, burn it at 1000°C for 10 h and then lower the temperature to room temperature, cut the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com