A kind of electrolysis-titanium carbon sulfur anode-method for preparing metal titanium

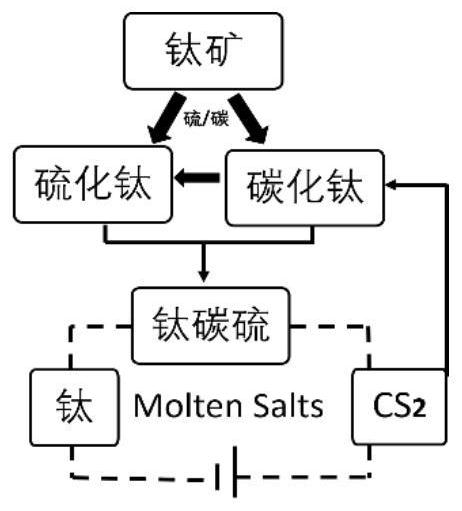

A technology of metal titanium and titanium carbon is applied in the field of molten salt extraction of high-purity titanium metal, which can solve the problems of inability to achieve high-purity titanium, unattainable product quality, and high energy consumption, and achieve high-efficiency comprehensive utilization and high-efficiency recycling. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

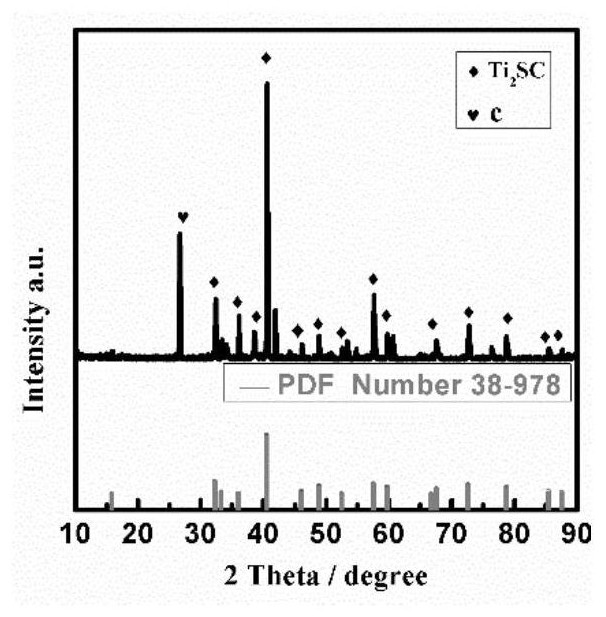

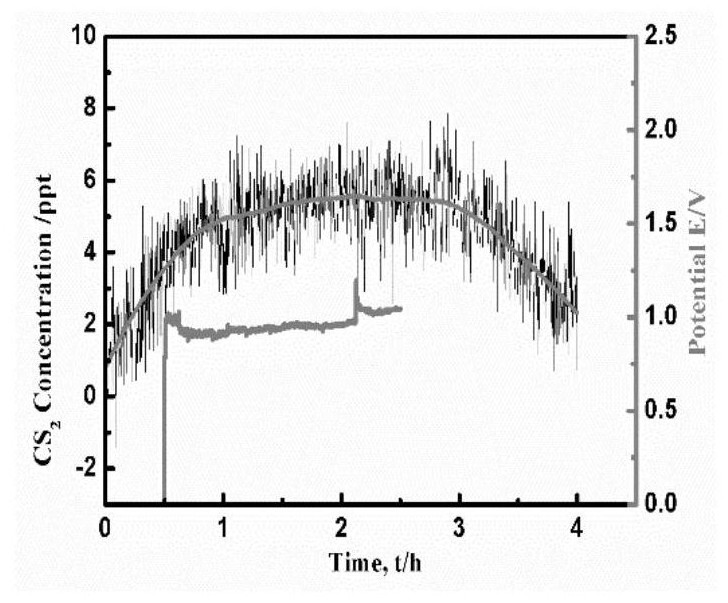

[0058] Titanium dioxide (TiO 2 , 99.5wt%), graphite powder (99.95), sulfur powder (99%) were prepared according to the molar ratio of 1:2:2.1, a total of 100g. Mix and grind in a spherical ball mill for 12 hours, weigh 5g and press it into a small piece with a diameter of 5mm*5mm under a pressure of 10Mpa, and place it in a closed glass tube at one end, and seal it with a high-temperature resistant organic glue to ensure that the glass tube No air leakage at high temperature. Then place the glass tube in a muffle furnace, burn it at 1000°C for 10 hours and then lower the temperature to room temperature, cut the glass tube and take out the TiS 2 Material. Using the titanium disulfide and titanium carbide for SPS sintering at 1450 °C, the final synthesis of Ti 2 CS ceramic material. The XRD diffraction pattern of the synthesized material is shown in the attached figure 2 shown. A corundum crucible containing 150 g of NaCl-KCl eutectic molten salt was used to carry out rel...

Embodiment 2

[0060] First, 500g of titanium concentrate FeTiO 3 Carbon and vulcanization treatment is carried out at 1200°C, and the processed products are FeS and Ti 2 CS mixed powder. Then the mixed powder is soaked in 1mol / L dilute hydrochloric acid, and vacuum filtered, then dried in an oven at 80°C to obtain titanium carbon sulfur ceramic material powder (Ti 2 CS). The anode was vacuum sintered and pressed into Ti 2 CS anode. Use a corundum crucible to hold 150g of NaCl-KCl-TiCl 2 The eutectic molten salt was subjected to relevant electrolysis at 750°C. Wherein the cathode adopts a nickel rod with a diameter of 2mm, and the reference electrode is an AgCl / Ag electrode of NaCl-KCl-AgCl (0.04wt%). The current density is 0.1A / cm 2 The constant current electrolysis for 4h, the gas generated by the anode will pass into the TiO 2 Preparation of TiS by reduction in a high-temperature reactor 2 Or TiS. Then the cathode product was ultrasonically cleaned with distilled water and 1wt% ...

Embodiment 3

[0062] TiS and TiC were prepared with a molar ratio of 1:1, mixed and ground in a star ball mill for 12 hours, and vacuum sintered to prepare Ti 2 CS anode. Use a corundum crucible to hold 150g of CaF 2 -KF-NaF-Na 2 TiF 6 The eutectic molten salt was subjected to relevant electrolysis experiments at 850 °C. Ti fired 2 CS is the anode, the anode current density is 0.5A / cm 2Under constant current electrolysis, the distance between cathode and anode is 5cm. After 4 hours of electrolysis, a titanium powder product is obtained on the cathode nickel rod. The gas generated by the anode is introduced into the Ti 2 In the CO tube furnace (1500°C), the gas generated during the electrolysis process will reduce the Ti 2 CO, to obtain the TiS product. The cathode product is soaked in distilled water and washed and dried with 1 wt% dilute hydrochloric acid. The final product is titanium powder with uniform phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com