Low-valence titanium sulfide as well as preparation method and application thereof

A low-valence, sulfide technology, used in titanium compounds, chemical instruments and methods, titanium sulfide, etc., to achieve the effects of reducing side reactions, excellent electrochemical performance, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

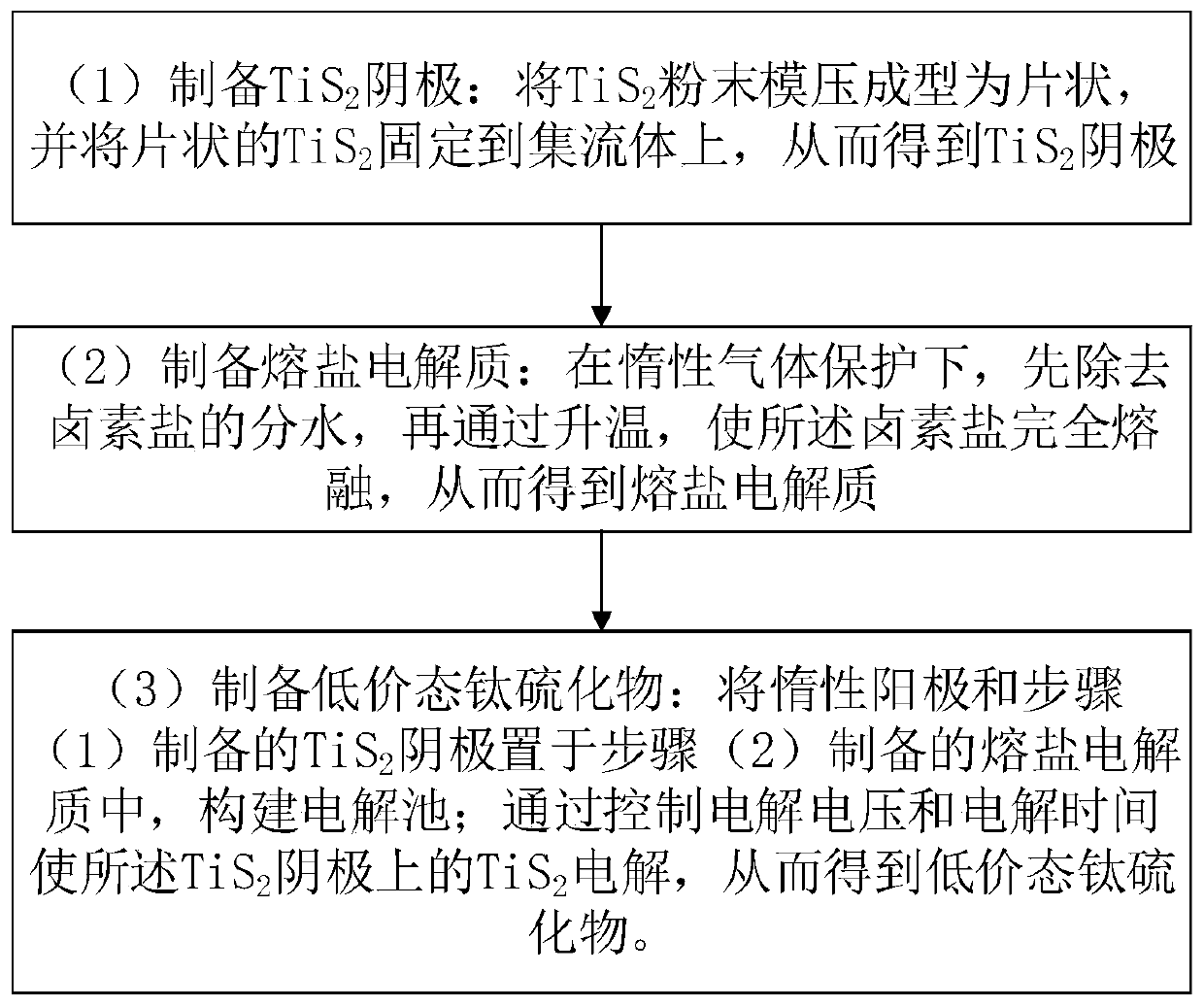

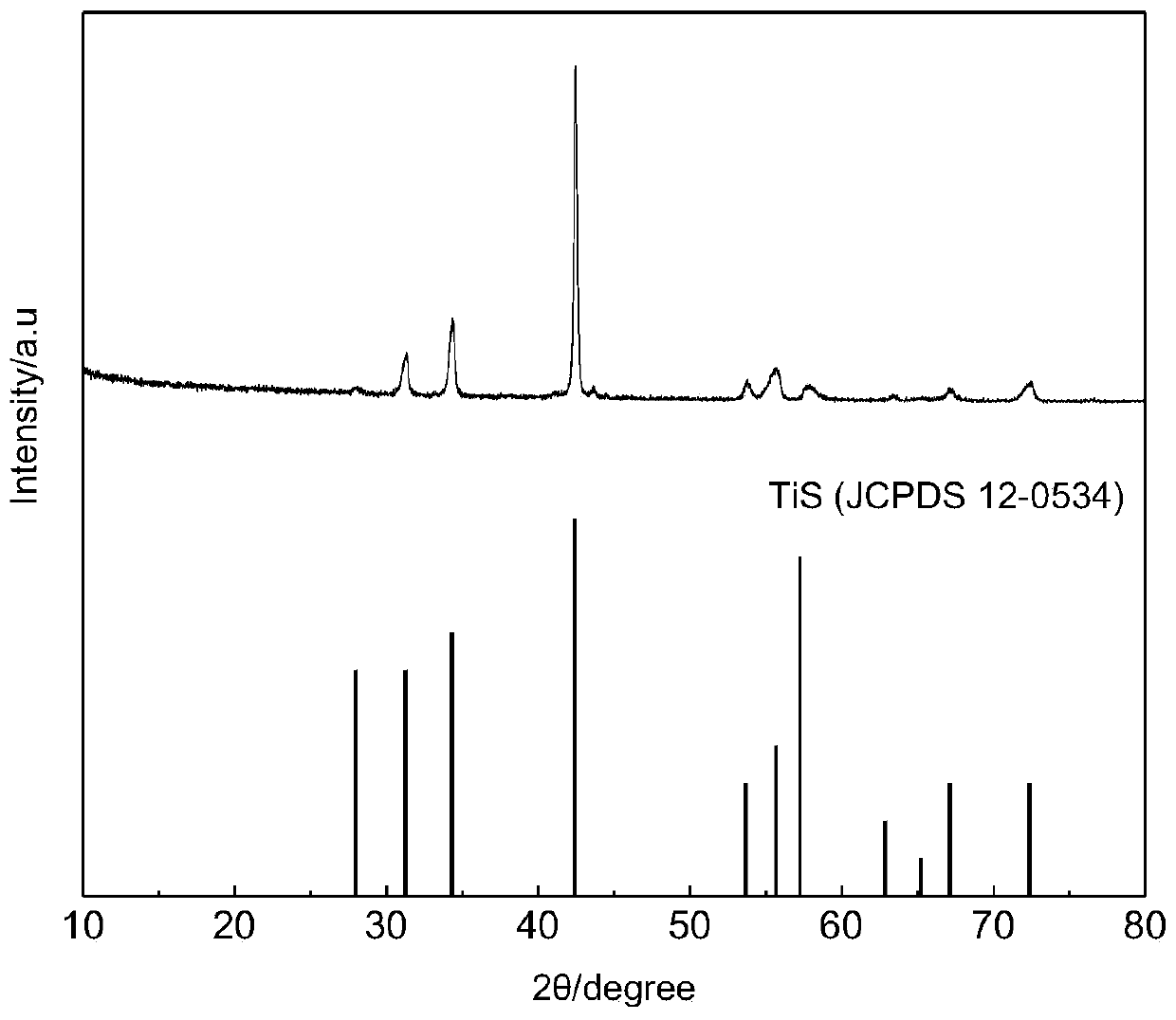

[0040] figure 1 A schematic flow diagram of a preparation method of a low-valent titanium sulfide provided by the present invention, comprising the following steps:

[0041] (1) Preparation of TiS 2 Cathode: TiS 2 powder compression molding into flakes, and flake TiS 2 fixed to the current collector, resulting in TiS 2 cathode;

[0042] Preferably, TiS in step (1) 2 The dosage is 0.3~1.5g, and the molding pressure is 10~30MPa;

[0043] (2) Preparation of molten salt electrolyte: under the protection of an inert gas, first remove the water separation of the halogen salt, and then heat up to completely melt the halogen salt, thereby obtaining a molten salt electrolyte;

[0044] Preferably, the halogen salt in step (2) includes at least one of the following: calcium chloride, potassium chloride, lithium chloride, and sodium chloride, and the melting temperature of the halogen salt is 300-900°C.

[0045] (3) Preparation of low-valent titanium sulfide: the inert anode and th...

Embodiment 1

[0049] This embodiment includes the following steps:

[0050] (1) Add 0.5g of TiS 2 Press the pressure of 20MPa into a flake with a diameter of 10mm, and the flake TiS 2 Wrapped with molybdenum mesh and fixed on molybdenum wire, it is used as electrolysis cathode.

[0051] (2) Weigh 150g of lithium chloride molten salt and place it in a graphite crucible with a diameter of 400mm and a depth of 20cm, and heat it at 120°C, 250°C and 450°C for 5h to remove water, and then at a speed of 3°C / min The temperature is raised to 700°C until lithium chloride is completely melted, and as a molten salt electrolyte for electrolysis, the whole process is completed under the protection of an argon atmosphere.

[0052] (3) In order to remove impurities in the molten salt electrolyte, before the electrolysis experiment starts, the molten lithium chloride prepared by step (2) is Electrolyte, electrolysis at 2.6V for 10h. Then replace the molybdenum wire cathode with TiS 2 Cathode, continue ...

Embodiment 2

[0058] This embodiment includes the following steps:

[0059] (1) Add 0.5g of TiS 2 Press the pressure of 20MPa into a flake with a diameter of 10mm, and the flake TiS 2 Wrapped with molybdenum mesh and fixed on molybdenum wire as electrolysis cathode;

[0060] (2) Weigh 150g of lithium chloride molten salt and place it in a graphite crucible with a diameter of 400mm and a depth of 20cm, and heat it at 120°C, 250°C and 450°C for 5h to remove water, and then at a speed of 3°C / min Raise the temperature to 700°C until the lithium chloride is completely melted, as the molten electrolyte for electrolysis, and the whole process is completed under the protection of an argon atmosphere.

[0061] (3) In order to remove impurities in the molten salt electrolyte, before the electrolysis experiment starts, the molten lithium chloride prepared by step (2) is Electrolyte, electrolysis at 2.6V for 10h. Then replace the molybdenum wire cathode with TiS 2 Cathode, continue to prepare the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com