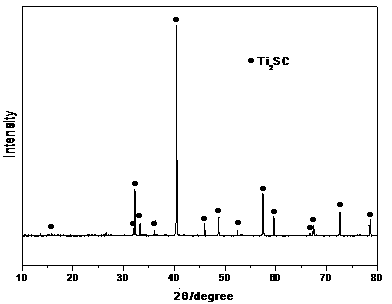

Novel method for synthesizing Ti2SC ceramic by microwave heating

A microwave synthesis and microwave heating technology is applied in the field of microwave synthesis of Ti2SC ceramic materials and microwave synthesis of inorganic ceramic materials, and achieves the effects of low equipment requirements, lower reaction temperature and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using titanium powder, titanium disulfide powder and graphite powder as raw materials, according to Ti:TiS 2 :C=(2.5~3):3:(1.0~1.2):2 The molar ratio is weighed, the powder is mixed evenly, pressed into a disc, and then the disc is heated in the cavity of the microwave heating device, and the reaction Under the protection of argon gas (argon gas flow rate 60~100ml / min), the sintering time is 15 minutes, and the sintering temperature is 800°C, and Ti can be prepared. 2 SC material.

Embodiment 2

[0019] Using titanium powder, titanium disulfide powder and graphite powder as raw materials, according to Ti:TiS 2 :C=(2.5~3):3:(1.0~1.2):2 The molar ratio is weighed, the powder is mixed evenly, pressed into a disc, and then the disc is heated in a microwave heating device, and the reaction is carried out under argon Ti 2 SC material.

Embodiment 3

[0021] Using titanium powder, titanium disulfide powder and graphite powder as raw materials, according to Ti:TiS 2 :C=(2.5~3):3:(1.0~1.2):2 The molar ratio is weighed, the powder is mixed evenly, pressed into a disc, and then the disc is heated in a microwave heating device, and the reaction is carried out under argon Under the protection of gas (argon gas flow rate 60~100ml / min), the sintering power is 1100°C, and the sintering time is 8 minutes, and Ti 2 SC material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com