Preparation method of surface-modified titanium sulfide battery negative electrode material

A technology of titanium carbon sulfide and battery negative electrode, which is applied in the field of preparation of surface-modified titanium carbon sulfide battery negative electrode materials, can solve the problems of restricting lithium storage potential, unfavorable lithium ion deintercalation, etc., and achieve lower diffusion energy barrier, low cost, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

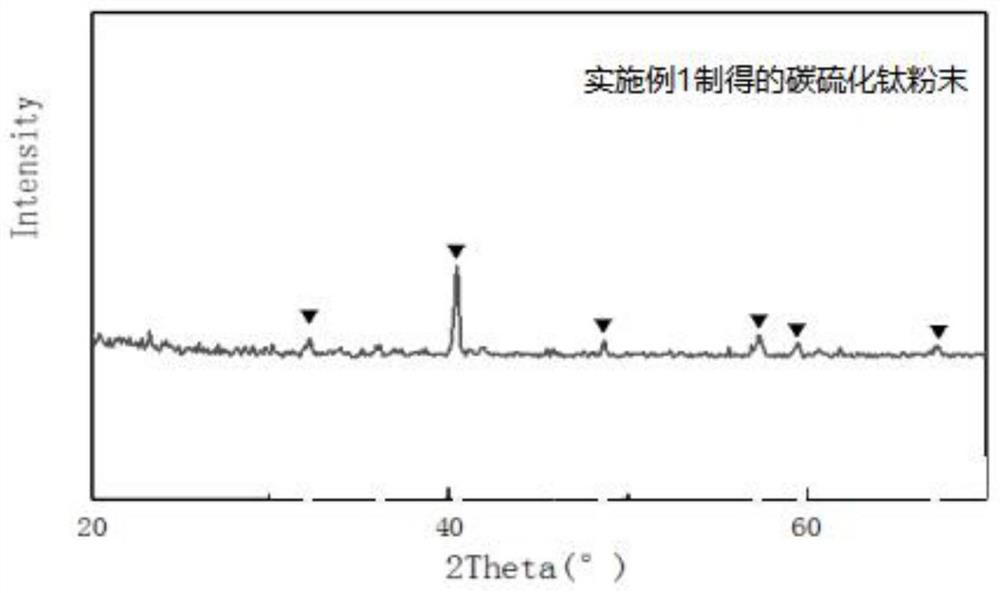

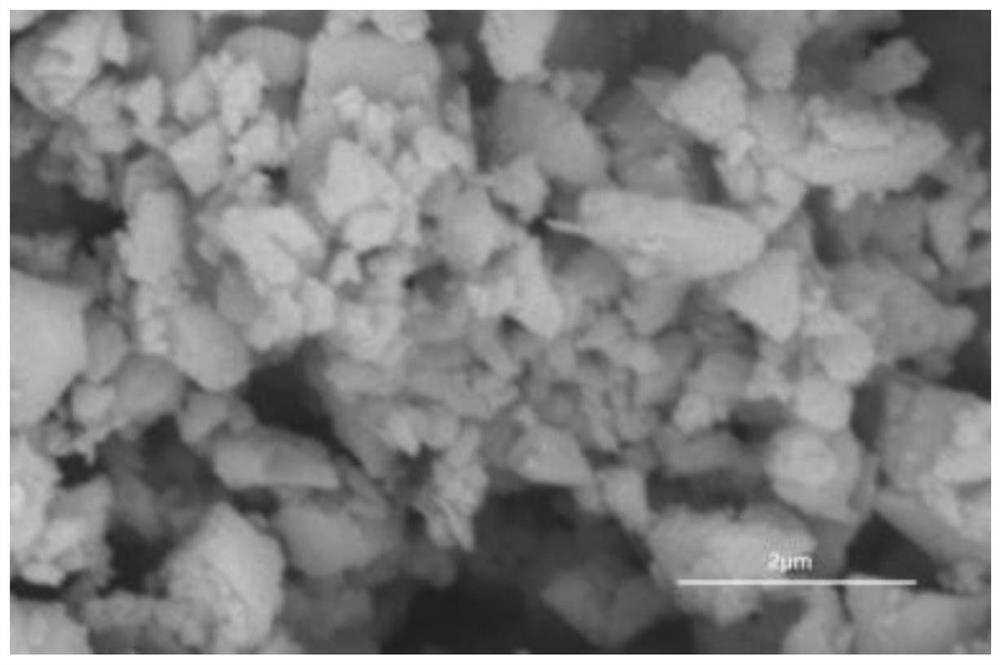

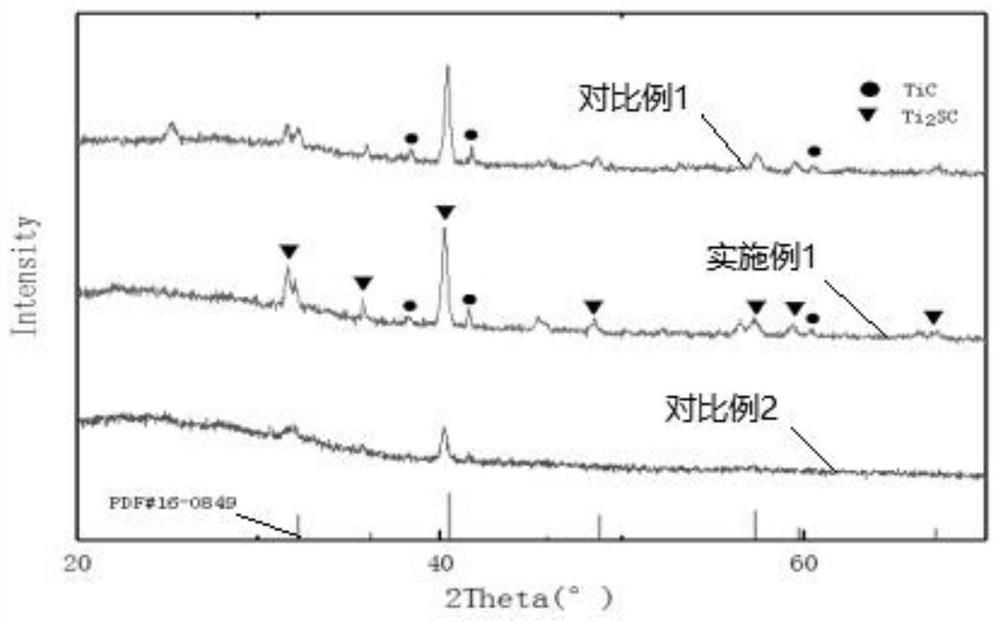

Embodiment 1

[0028] A method for preparing a surface-modified titanium carbon sulfide battery negative electrode material, comprising the steps of:

[0029] (1) Put titanium powder, sulfur powder and graphite powder into the ball mill tank at a molar ratio of 2:1:1, and control the ball-material ratio in the tank to 4:1, and the mass ratio of small, medium and large steel balls to 3:4: 3. Pass argon as the protective gas, conduct ball milling, control the relative humidity ≤ 60%, set the parameters to 300r / min, and ball milling time to 3h, to obtain the mixed powder;

[0030] (2) Add the mixed powder into the self-propagating synthesis reaction kettle, pass argon as the protective gas, and keep the pressure in the reaction kettle at 0.26MPa after three times of gas washing, turn on the low-pressure ignition, and carry out the high-temperature self-propagating reaction (100°C, 5min), obtain block sample;

[0031] (3) Roughly crush the bulk sample and put it into the ball mill tank. Control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com