Lithium titanium sulfide, lithium niobium sulfide, and lithium titanium niobium sulfide

一种硫化物、锂钛的技术,应用在钛化合物、铌化合物、无机化学等方向,能够解决铌硫化物少、尚无材料开发例、无报告等问题,达到结构稳定化、充电容量优异、充放电电位优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

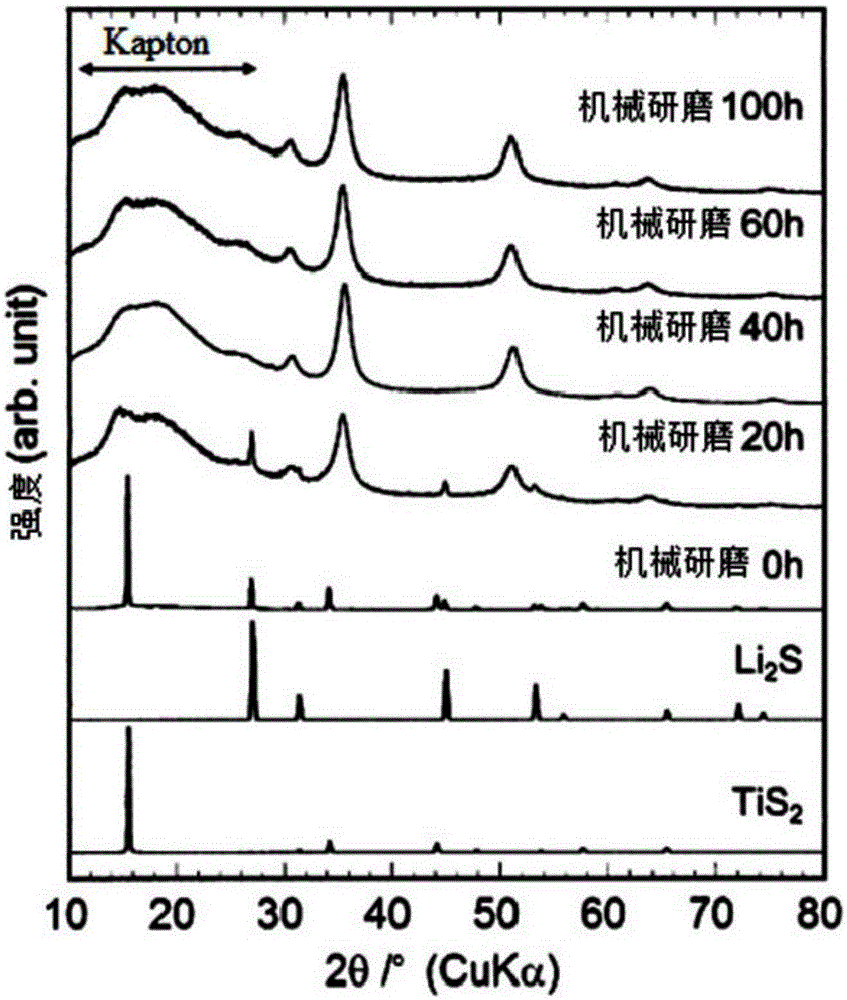

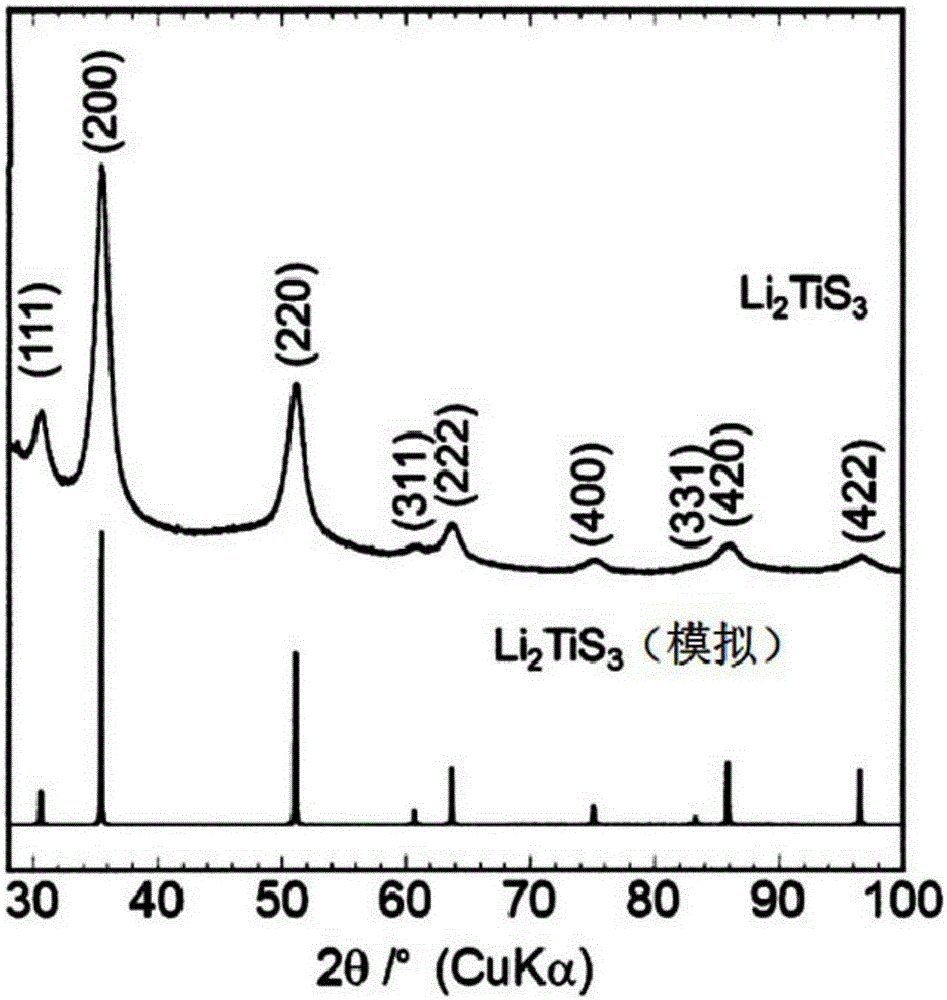

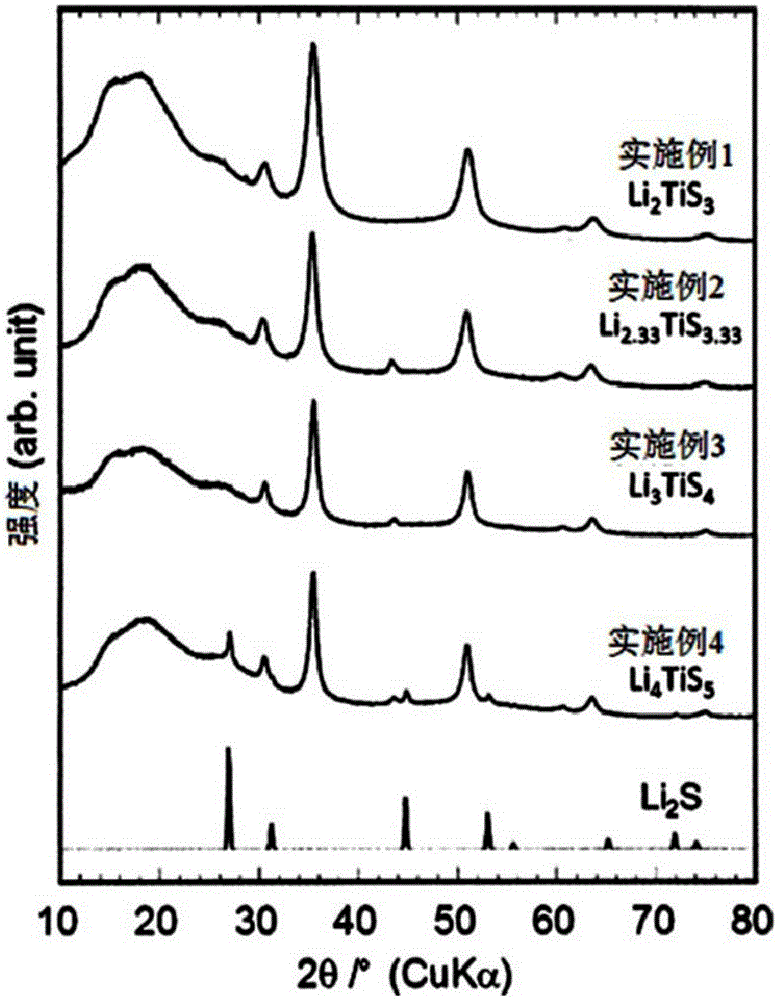

[0223] [Example 1: Li 2 TiS 3 Synthesis of powder]

[0224] Weigh and mix commercially available lithium sulfide (Li 2 S) powder, and titanium disulfide (TiS 2 ) powder, and then use a 45mL container with about 500 zirconia balls with a diameter of 4mm, and perform a mechanical grinding process at 510rpm for 20 to 100 hours with a ball mill (FritschP7, Classicline), thereby obtaining Li 2 TiS 3 powder.

Embodiment 2

[0225] [Example 2: Li 2.33 TiS 3.33 Synthesis of powder]

[0226] Weigh and mix commercially available lithium sulfide (Li 2 S) powder, titanium disulfide (TiS 2 ) powder and sulfur (S) powder, and then use a 45mL container with about 500 zirconia balls with a diameter of 4mm to carry out mechanical grinding at 510rpm for 40 hours with a ball mill (FritschP7, Classicline), thereby obtaining Li 2.33 TiS 3.33 powder.

Embodiment 3

[0227] [Example 3: Li 3 TiS 4 Synthesis of powder]

[0228] Weigh and mix commercially available lithium sulfide (Li 2 S) powder, titanium disulfide (TiS 2 ) powder and sulfur (S) powder, and then use a 45mL container with about 500 zirconia balls with a diameter of 4mm to carry out mechanical grinding at 510rpm for 40 hours with a ball mill (FritschP7, Classicline), thereby obtaining Li 3 TiS 4 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diffraction angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com