Hydrogenation catalyst and preparation method thereof, and application of hydrogenation catalyst in catalyzing tetrahydrofurfuryl alcohol hydrogenation to prepare 1,5-pentanediol

A hydrogenation catalyst and catalyst technology, which are applied in chemical instruments and methods, physical/chemical process catalysts, and preparation of oxygen-containing functional groups reduction, etc., can solve the problems of increasing difficulty in ring opening, low cost, poor stability, etc., and achieve improved stability. With the effect of activity, improving electron transfer performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

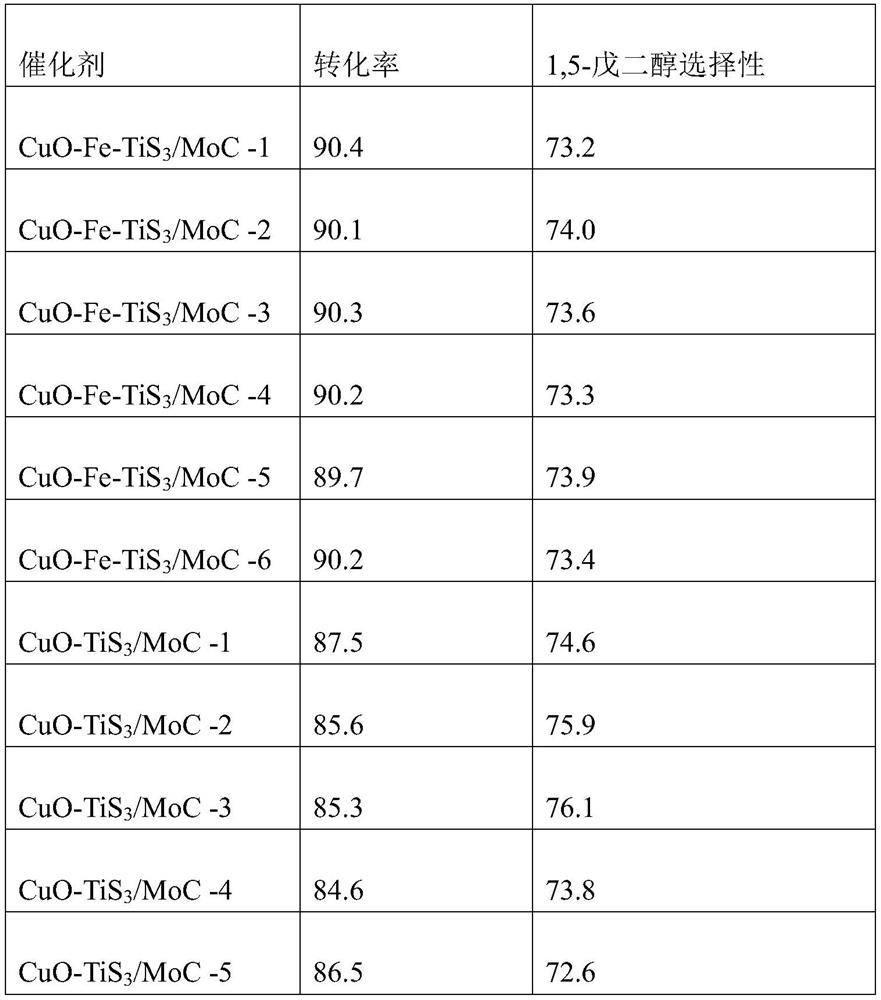

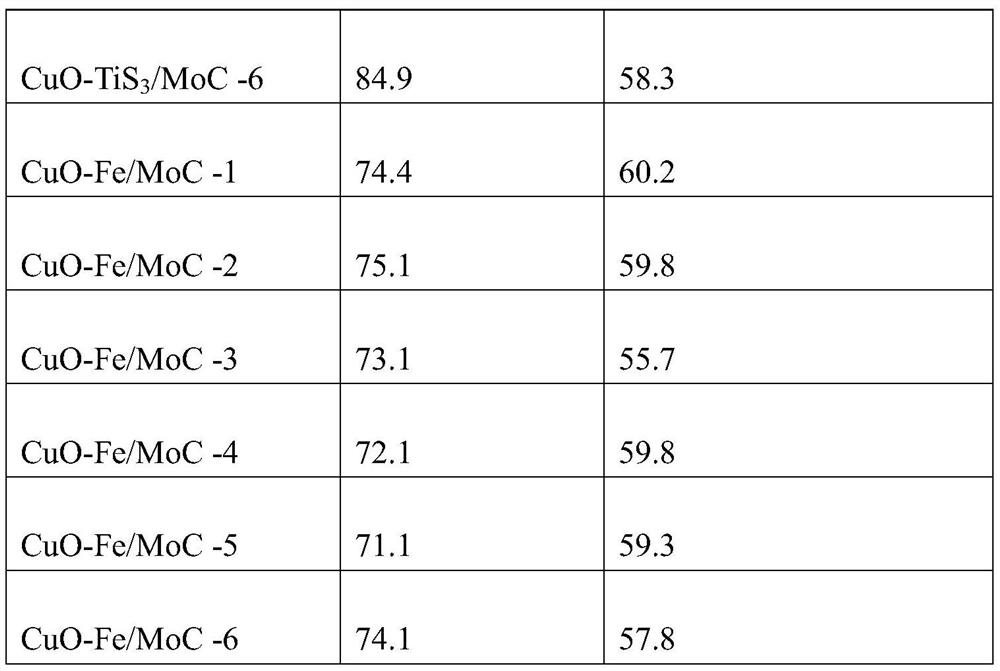

Examples

Embodiment 1

[0036] Catalyst preparation:

[0037] Add 20g of deionized water to the beaker, weigh 4g of anhydrous copper chloride powder, and ultrasonically shake for 3 hours to dissolve it;

[0038] Prepare 20g of ethylenediamine solution with a concentration of 20wt.%, stir and heat to 40°C, slowly pour in the prepared copper chloride solution, observe the uniform color and stir for 2 hours, pour the copper chloride solution into the hydrothermal kettle, add 12g Citric acid is used as a reducing agent, 2MPa hydrogen pressure reduction at 150°C for 8h to obtain a copper oxide mixture, 1.11g of ferrous chloride is added to the mixture, and 2MPa hydrogen pressure reaction at 150°C for 4h;

[0039] Use 1g of deionized water to ultrasonically disperse 0.4g of titanium trisulfide for 2 hours, add it to the copper oxide mixed solution, then add 12g of molybdenum carbide powder to the above mixed solution, mix it uniformly by ultrasonic and impregnate for 1 hour, filter and dry to obtain a powd...

Embodiment 2

[0043] Catalyst preparation:

[0044] Add 20g of deionized water to the beaker, weigh 0.2g of anhydrous copper sulfate powder, and ultrasonically shake for 3 hours to dissolve it;

[0045] Prepare 20g of EDTA-2Na solution with a concentration of 2wt.%, stir and heat to 40°C, slowly pour into the prepared copper sulfate solution, observe the uniform color and stir for 2h, pour the copper sulfate solution into the hydrothermal kettle, add 2g of citric acid As a reducing agent, 4MPa hydrogen pressure reduction at 120°C for 10h to obtain a copper oxide mixture, add 0.1g cobalt chloride to the mixture, and react with 4MPa hydrogen pressure at 120°C for 8h;

[0046] Ultrasonic disperse 0.013g of titanium trisulfide with 0.1g of deionized water for 2 hours, add it to the copper oxide mixed solution, then add 2g of molybdenum carbide powder to the above mixed solution, mix it uniformly by ultrasonic and impregnate for 1.5 hours, filter and dry to obtain powder, the obtained The powde...

Embodiment 3

[0048] Catalyst preparation:

[0049] Add 20g of deionized water into the beaker, weigh 2.0g of anhydrous copper sulfate powder, and ultrasonically shake for 5 hours to dissolve it;

[0050] Prepare 20g of polyvinylpyrrolidone (K30, M=8000) solution with a concentration of 5wt.%, stir and heat to 40°C, slowly pour into the prepared copper sulfate solution, observe the uniform color and stir for 2h, pour the copper sulfate solution into the hot water In the kettle, add 8.0g oxalic acid as a reducing agent, reduce under 3MPa hydrogen pressure at 140°C for 10h to obtain a copper oxide mixture, add 0.4g potassium dichromate to the mixture, and react under 3MPa hydrogen pressure at 140°C for 20h;

[0051] Use 1g of deionized water to ultrasonically disperse 0.15g of titanium trisulfide for 2 hours, add it to the copper oxide mixed solution, then add 10g of molybdenum carbide powder to the above mixed solution and mix it uniformly for 1.5 hours, then filter and dry to obtain a powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com