A kind of vanadium-titanium sulfide catalyst and its preparation method and application

A technology of titanium catalyst and vanadium sulfide, which is applied in the field of vanadium-titanium sulfide catalyst and its preparation, can solve the problems of decreased selectivity, narrow operating temperature window, complex catalyst components, etc., and achieve the effect of improving low-temperature activity and wide operating temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

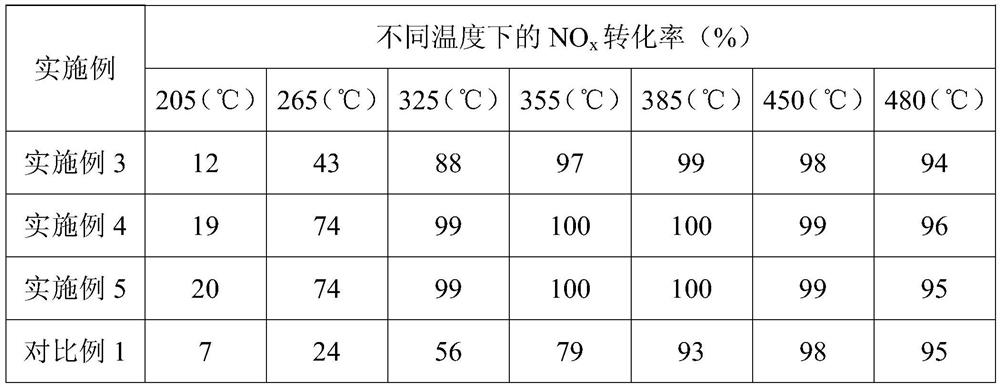

Examples

Embodiment 1

[0035] The vanadium-titanium sulfide catalyst of the present embodiment is made of sulfided TiO 2 is the carrier and the V loaded on the carrier 2 o 5 The active component consists of sulfurized TiO 2 The mass of the carrier is 100%, V 2 o 5 The mass of active ingredient is 1%.

[0036] The preparation method of described vanadium titanium sulfide catalyst comprises the steps:

[0037] 1) Dissolve ammonium sulfate in water, add TiO to the ammonium sulfate solution 2 The carrier was stirred ultrasonically for 1h, wherein ammonium sulfate and TiO 2 The mass ratio of the carrier is 8%, evaporated to dryness by a rotary evaporator at 60°C, dried in an oven at 100°C, and roasted in a muffle furnace at 300°C for 3 hours in an air atmosphere to obtain sulfide TiO 2 carrier;

[0038] 2) In the presence of oxalic acid, the sulfurized TiO obtained in step 1) 2 The carrier was added into the ammonium metavanadate solution and stirred ultrasonically for 1 hour, evaporated to dryn...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that V 2 o 5 The quality of active component is 3%, and all the other are identical with embodiment 1.

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is that ammonium sulfate and TiO 2 The mass ratio of the carrier is 8%, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com