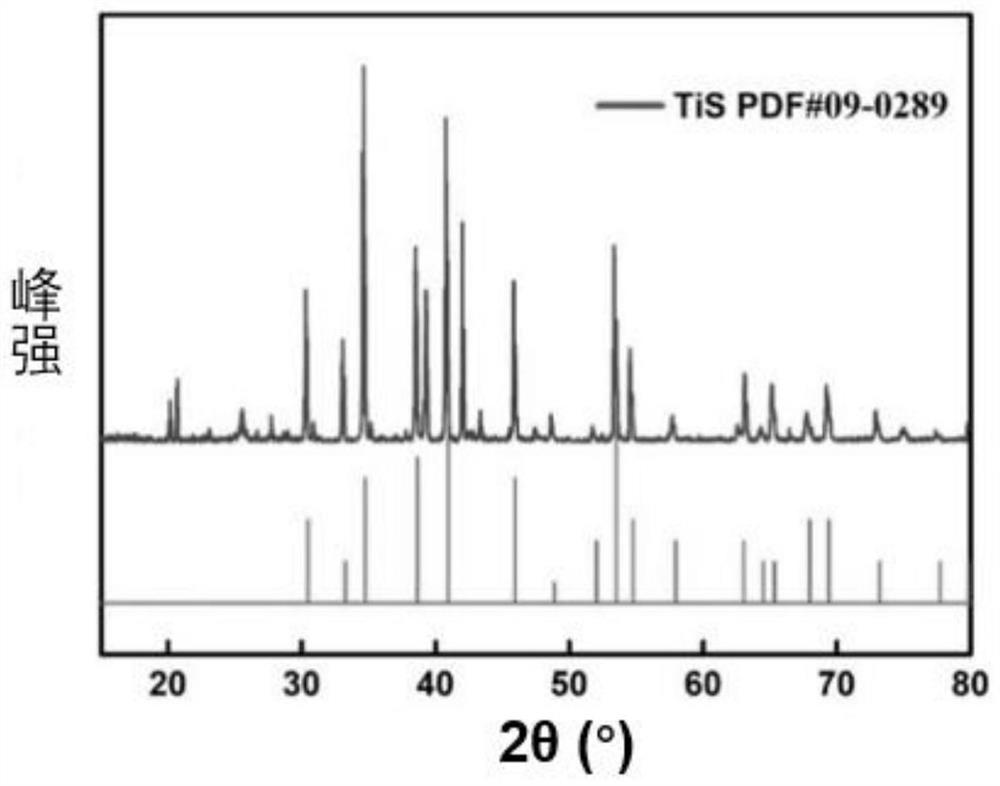

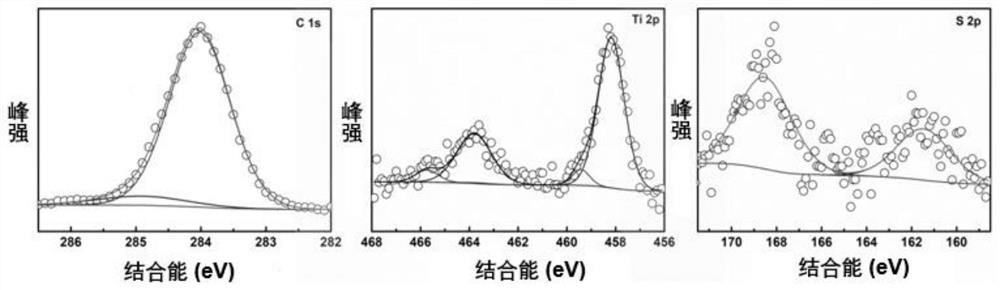

Titanium monosulfide particles and composite material thereof, preparation, application and coating material thereof

A composite material, titanium monosulfide technology, applied in metal material coating process, titanium sulfide, coating and other directions, can solve the problems of complex production process, high cost and high friction coefficient of coating materials, achieve great practical value, preparation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A preparation method of titanium monosulfide particles, comprising the following steps:

[0058] Step (1), screening titanium powder and sulfur powder with a size lower than 50 microns through a sieve, and mixing the screened fine powder or particles in a physical mixer to obtain a mixed powder;

[0059] Step (2), adding the mixed powder into deionized water, ultrasonically vibrating for 36 hours, putting the ultrasonicated liquid into a reaction kettle, reacting at 100 degrees Celsius for 12 hours, and naturally cooling to room temperature;

[0060] Step (3), after the reaction finishes, collect the reaction product, use a centrifuge to separate at 1000rpm, and take out the black solid precipitate;

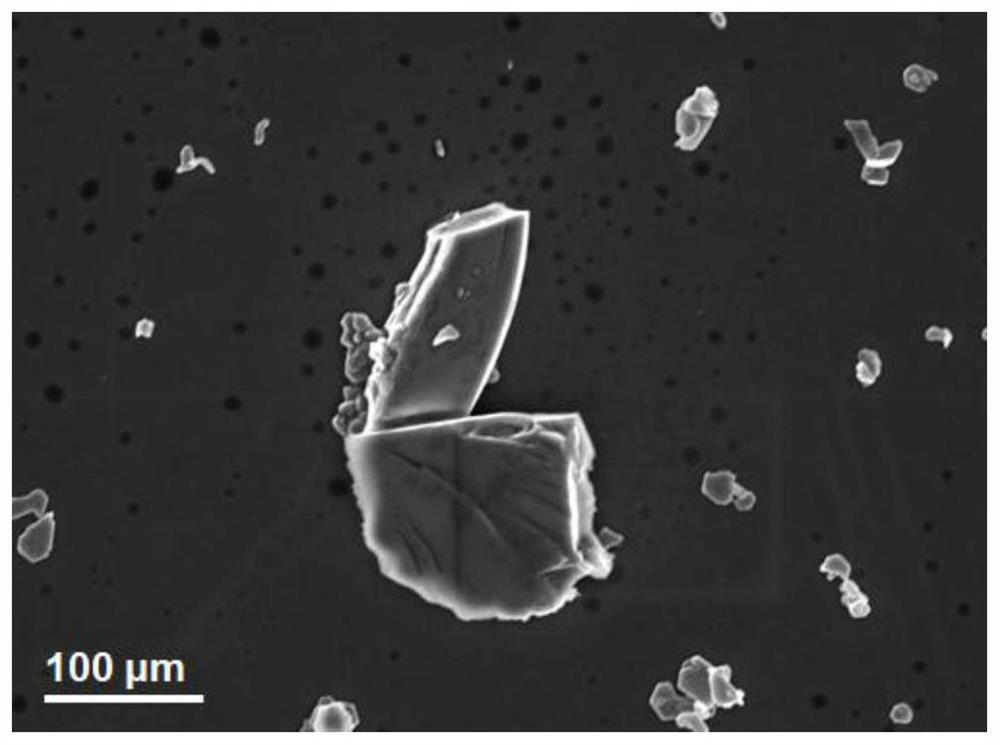

[0061] Step (4), reacting the black solid precipitate with 1mol / L hydrofluoric acid to remove oxide and nitride impurities, and hydrofluoric acid also etches the oxide and nitride impurities between the layered structure of the black solid precipitate The layered structur...

Embodiment 2

[0074] A preparation method of titanium monosulfide loaded zirconia composite material:

[0075] Step (1), mixing titanium powder and sulfur powder, and using a screening machine to select fine powder or particles with a size lower than 50 microns to obtain a mixed powder;

[0076] Step (2), adding the mixed powder into deionized water, ultrasonically vibrating for 38 hours, putting the ultrasonicated liquid into a reaction kettle, reacting at 100 degrees Celsius for 16 hours, and naturally cooling to room temperature;

[0077] Step (3), after the reaction finishes, collect the reaction product, use a centrifuge to separate at 1200rpm, and take out the black solid precipitate;

[0078] Step (4), black solid is reacted with 4mol / L hydrofluoric acid to remove impurities such as oxides and nitrides, and the reacted black solid is cleaned and dried to finally obtain black solid which is pure titanium monosulfide ( TiS) material;

[0079] Wherein, the mass ratio of titanium powde...

Embodiment 3

[0086] A preparation method of titanium monosulfide particles, comprising the following steps:

[0087] Step (1), mixing titanium powder and sulfur powder, and selecting fine powder or particles with a size lower than 50 microns by using a screening machine;

[0088] Step (2), adding the mixed powder into deionized water, ultrasonically vibrating for 42 hours, putting the ultrasonicated liquid into a reaction kettle, reacting at 130 degrees Celsius for 16 hours, and naturally cooling to room temperature;

[0089] Step (3), after the reaction finishes, collect the reaction product, use a centrifuge to separate at 1500rpm, and take out the black solid precipitate;

[0090] Step (4), black solid precipitate is reacted with the hydrofluoric acid of 10mol / L, removes oxide and nitride impurity, and hydrofluoric acid also engraves oxide and nitride impurity between black solid precipitate layered structure etched away to highlight the layered structure, and then the black solid afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com