Optical glasses of the dense barium flint position

A kind of optical glass and glass technology, applied in the field of optical glass, can solve the problems of inability to obtain optical position, small ZrO2 content, harmful crystallization stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

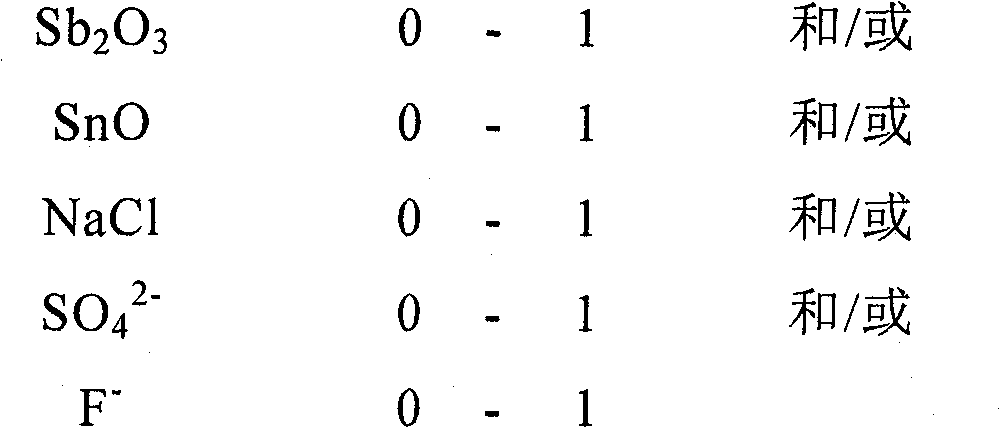

[0103] Tables 2 and 3 show 12 examples of preferred compositional ranges. The glasses described in these examples were prepared as follows:

[0104] The raw material of the oxide, preferably the corresponding carbonate, is weighed, and one or more clarifying agents such as e.g. Sb 2 o 3 and mix well. The batch was melted at 1250° C. in a discontinuously operating melting plant, subsequently refined (1350° C.) and homogenized. The glass can be cast at a casting temperature of about 900°C and processed into the desired shape. In high volume continuously operating melting plants, the temperature can be reduced by at least 100 K and the material can be processed in a near net shape hot molding process such as precision pressing.

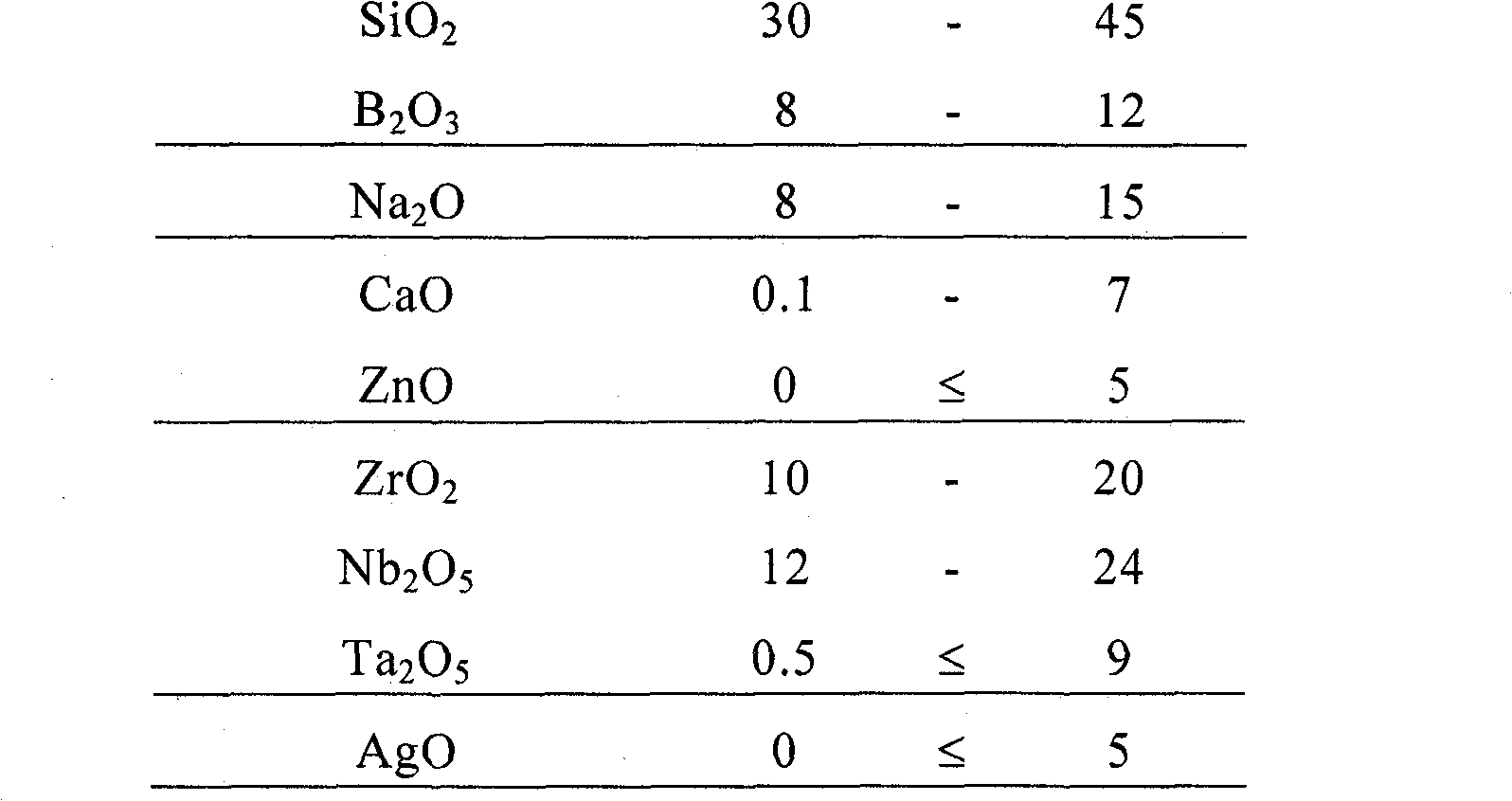

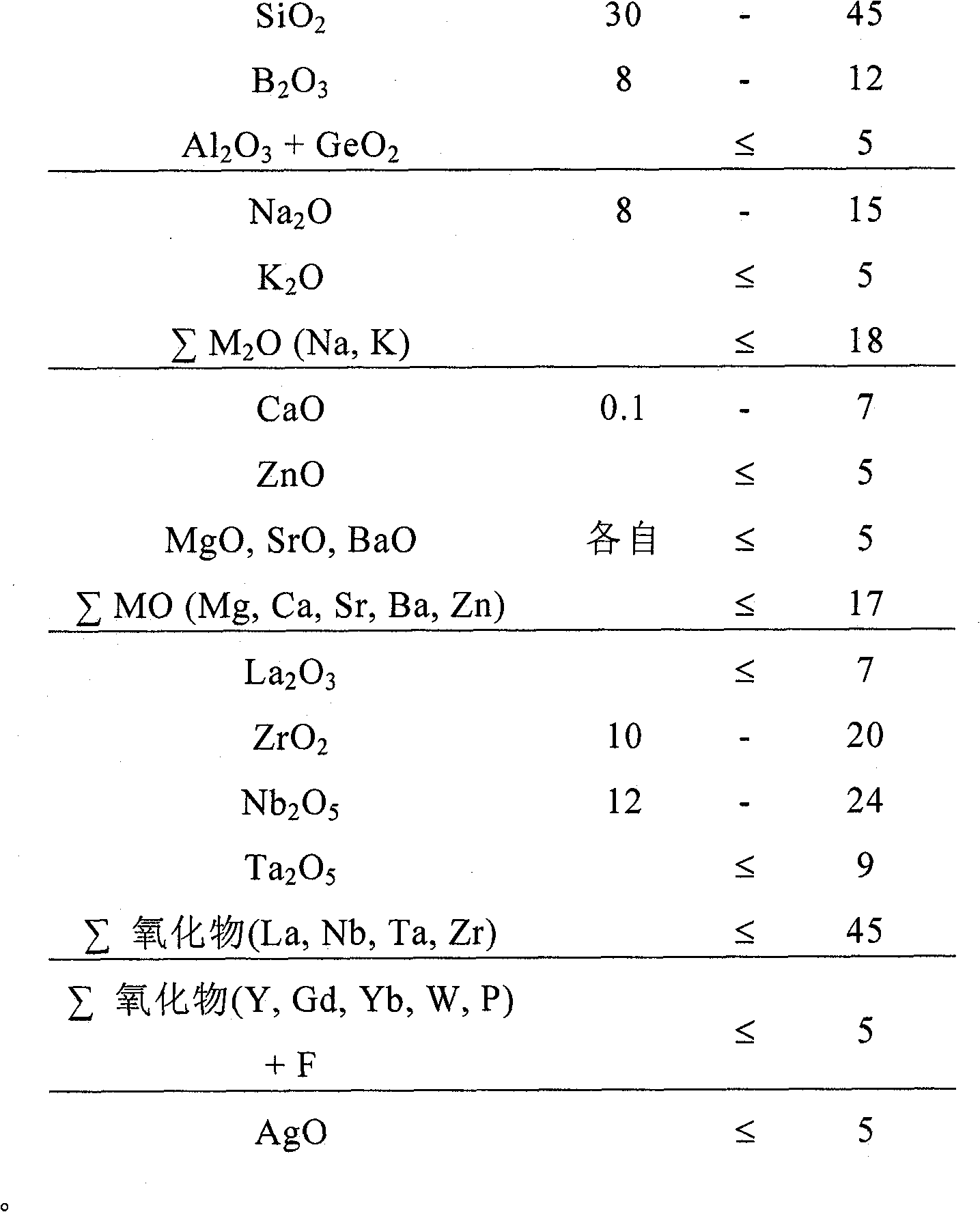

[0105] Table 1

[0106] Melting examples, based on 100kg of glass:

[0107]

[0108] As in Example 1, the properties of the glass obtained are given in Table 2. Close to the measurements described therein, the glass exhibits excellent chemical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com