Application of a Supported Single-Atom Noble Metal Catalyst in the Esterification of Unsaturated Hydrocarbon Carboxymethyl

A noble metal catalyst, supported technology, applied in the direction of carbon monoxide or formate reaction preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the disadvantages of homogeneous catalysts, not very economical and environmentally friendly, difficult catalysts Problems such as recovery and separation, to achieve high activity and selectivity, easy separation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

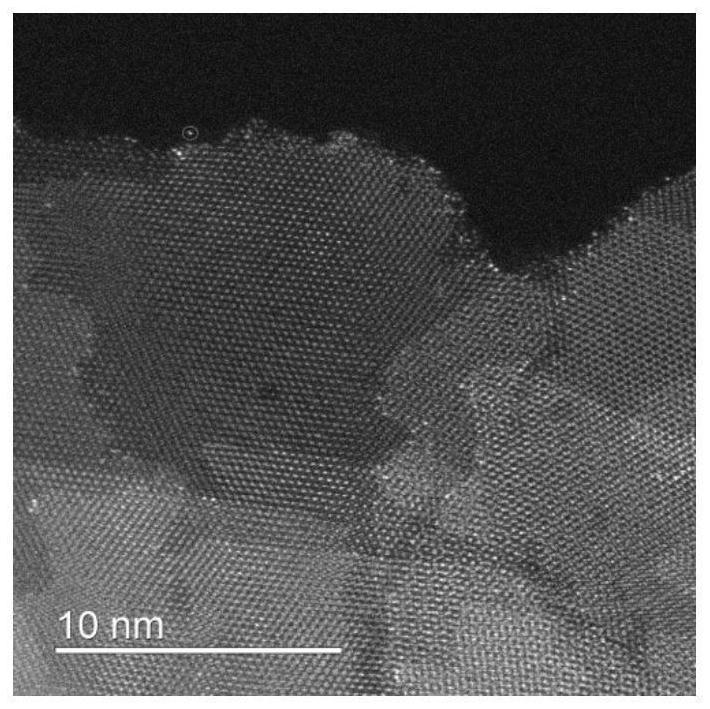

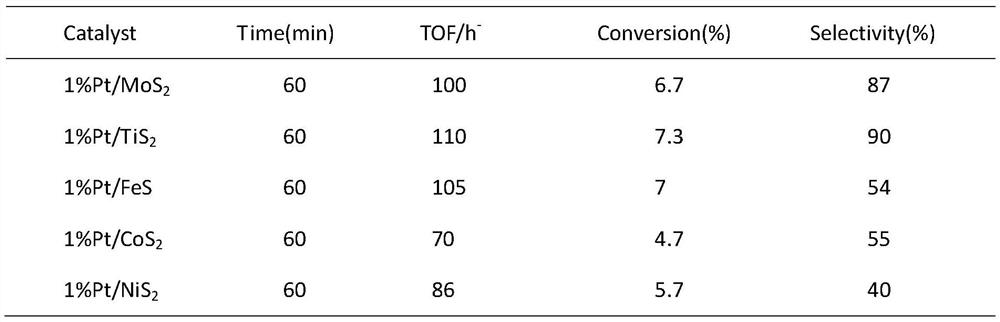

[0029] Example 1: Dissolve 0.027g of chloroplatinic acid in 5g of deionized water, add 0.5g of ethylenediamine organic reagent, stir for 1h, then add 1g of molybdenum sulfide, stir for 2h, filter and wash, place in an oven at 120°C, Dry for 12 hours to obtain a supported highly dispersed platinum-based catalyst precursor, then place the precursor in a quartz tube, and treat it at 500° C. for 120 minutes under Ar conditions to obtain a 1% Pt / MoS2 catalyst, which is then used in a desiccator. It can be seen by spherical aberration electron microscopy that the active components are dispersed on the carrier in the form of single atoms.

Embodiment 2

[0030] Example 2: Dissolve 0.015g of ruthenium chloride in 20g of deionized water, add 0.5g of 25% ammonia water, stir for 3h, then add 1g of molybdenum disulfide, stir for 5h, filter and wash, place in an oven at 60°C, Dry for 8 hours to obtain a supported highly dispersed ruthenium-based catalyst precursor, then place the precursor in a quartz tube, and treat it at 600° C. for 100 minutes under He conditions to obtain a 1% Ru / MoS2 catalyst, which is then used in a desiccator. It can be seen by spherical aberration electron microscopy that the active components are dispersed on the carrier in the form of single atoms.

Embodiment 3

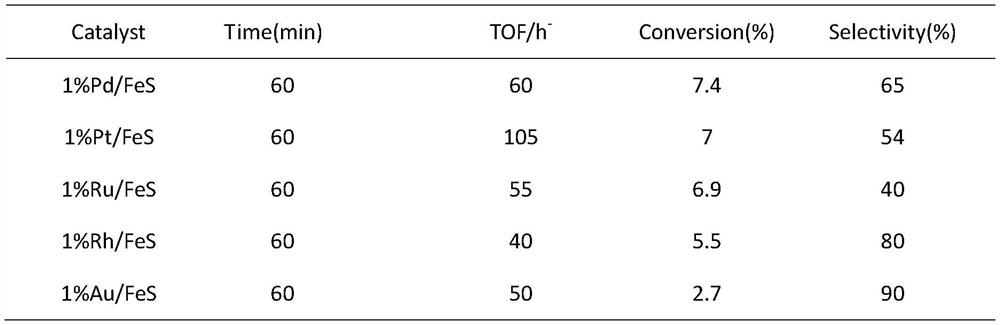

[0031] Example 3: Dissolve 0.027g of chloroplatinic acid in 5g of deionized water, add 0.5g of ethylenediamine organic reagent, stir for 1h, then add 1g of iron sulfide, stir for 2h, filter and wash, place in an oven at 120°C, Dry for 12 hours to obtain a supported highly dispersed platinum-based catalyst precursor, then place the precursor in a quartz tube, and treat it at 500° C. for 120 minutes under Ar conditions to obtain a 1% Pt / FeS catalyst, which is then placed in a desiccator for use. It can be seen by spherical aberration electron microscopy that the active components are dispersed on the carrier in the form of single atoms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com