Gas-phase cerium titanium sulfide supported tin oxide catalyst and preparation method and application thereof

A tin oxide and catalyst technology, which is applied in the field of gas-phase cerium sulfide titanium-supported tin oxide catalyst and its preparation, can solve the problems of poor mechanical strength and small specific surface area, and achieve good thermal stability, large specific surface area, and simple and quick operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

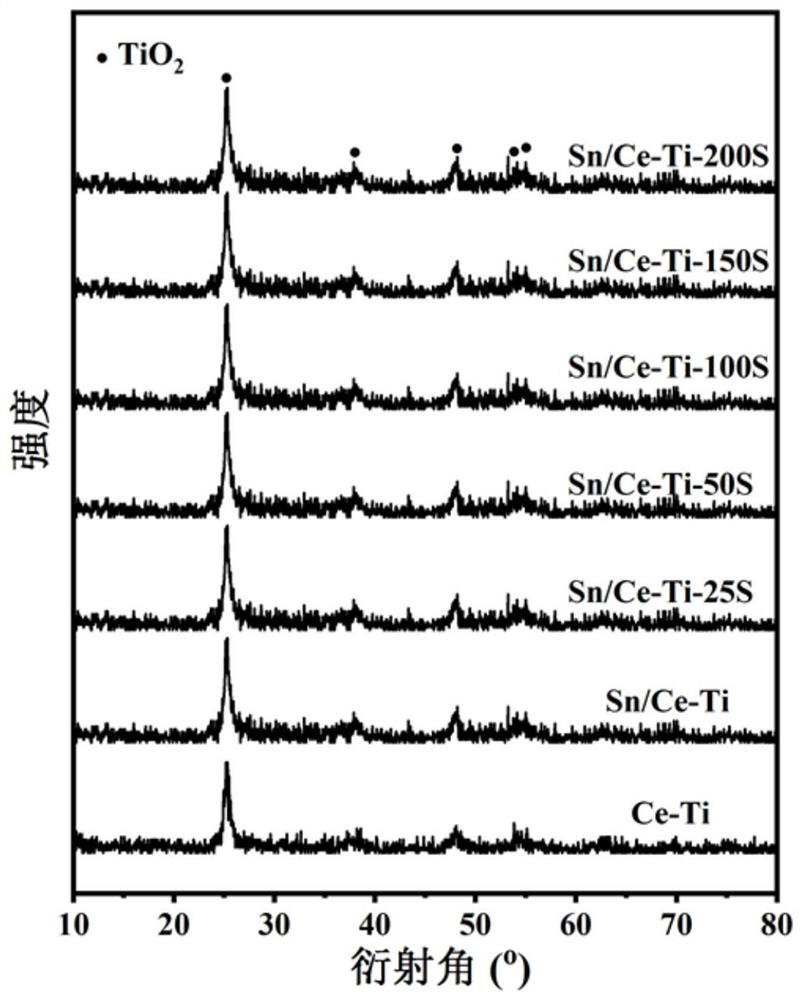

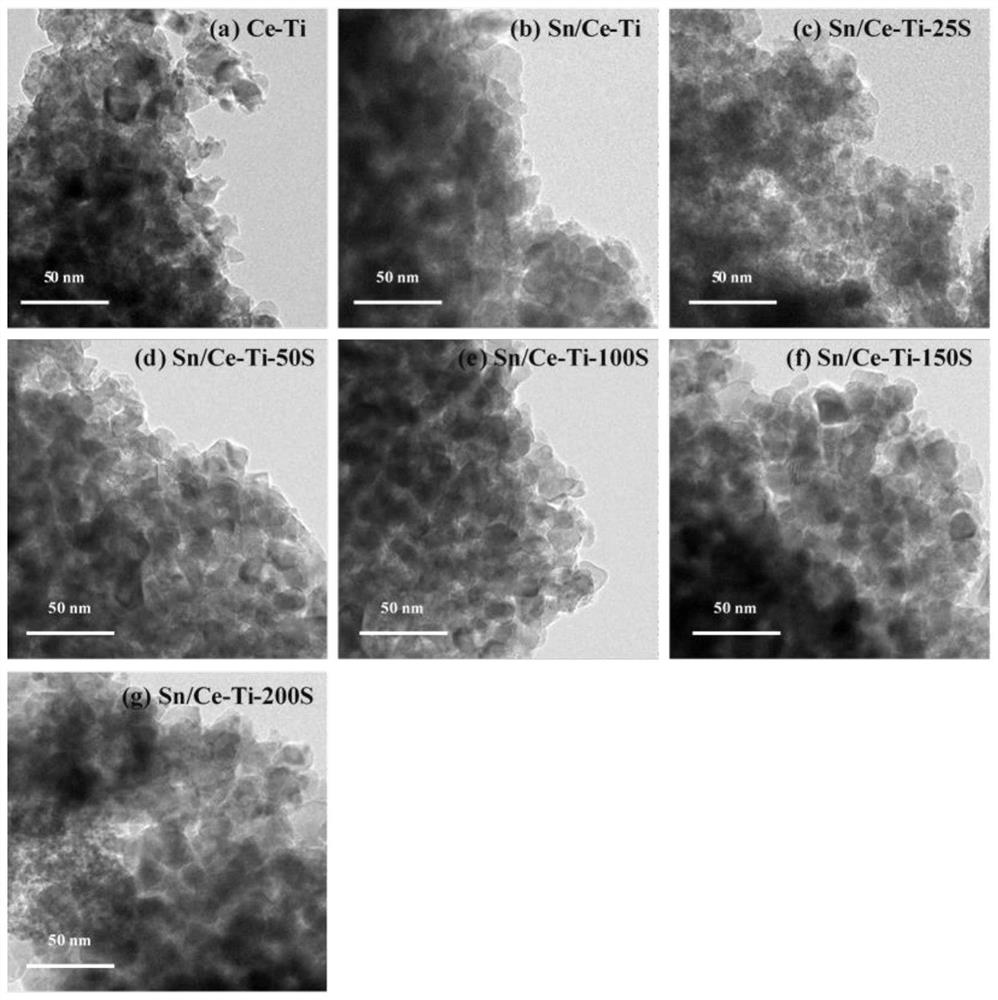

[0033] Preparation of Ce-Ti Solid Solution Support

[0034] Dissolve 9.02g of titanium sulfate and 0.82g of cerium nitrate in 200mL of ultrapure water, stir magnetically at room temperature for 30min to mix evenly, then add 25wt.% ammonia water drop by drop, adjust to pH = 10, stir and age in a constant temperature oil bath at 90°C for 3h , filter the obtained precipitate with suction, fully wash with ultrapure water until pH = 7, dry in an electric blast drying oven at 80°C for 12 hours, cool, grind, and heat up to 550°C in an air atmosphere at a heating rate of 2°C / min Calcined for 5h to obtain Ce-Ti solid solution carrier.

[0035] Preparation of Sn / Ce-Ti Catalyst

[0036] Add 1g Ce-Ti solid solution support to 28.25mL 0.02mol L -1 In the tin chloride solution, stir magnetically for 30 minutes to make it fully mixed, stir in a constant temperature oil bath at 90°C until the solution is evaporated to dryness, dry in an electric blast drying oven at 80°C for 12 hours, cool,...

Embodiment 2

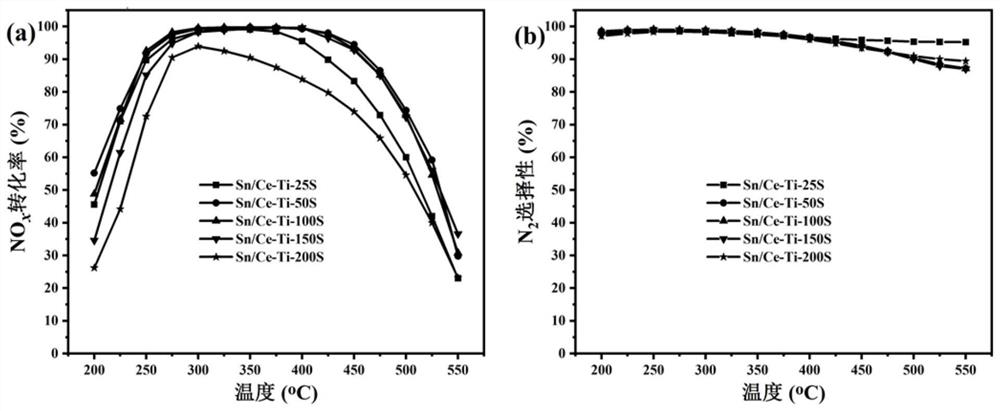

[0040] Preparation of Sn / Ce-Ti-50S Catalyst

[0041] The method of implementation 1 was used to prepare Ce-Ti solid solution carrier and Sn / Ce-Ti catalyst in sequence.

[0042] The prepared Sn / Ce-Ti catalyst was immobilized in the quartz tube in the heating furnace area of the SCR catalytic reaction platform, under N 2 Under the atmosphere, the temperature was raised from room temperature to 200 °C at a rate of 10 °C / min, and kept for 30 min, and the N 2 . Feed 50ppm SO 2 30min, close SO 2 , into N 2 1h, down to room temperature, the Sn / Ce-Ti-50S catalyst is obtained.

Embodiment 3

[0044] Preparation of Sn / Ce-Ti-100S Catalyst

[0045] The method of implementation 1 was used to prepare Ce-Ti solid solution carrier and Sn / Ce-Ti catalyst in sequence.

[0046] The Sn / Ce-Ti catalyst was immobilized in the quartz tube in the heating furnace area of the SCR catalytic reaction platform, under N 2 Under the atmosphere, the temperature was raised from room temperature to 200 °C at a rate of 10 °C / min, and kept for 30 min, and the N 2 . Feed 100ppm SO 2 30min, close SO 2 , into N 2 1h, down to room temperature, the Sn / Ce-Ti-100S catalyst is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com