A kind of preparation method of two-dimensional material

A two-dimensional material and raw material technology, applied in the field of nanomaterials, can solve the problems of molybdenum sulfide sheets with reduced catalytic performance and photoelectric performance, molybdenum sulfide nanosheets with functional groups, etc., to achieve easy large-scale production, improve comprehensive economic benefits, highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

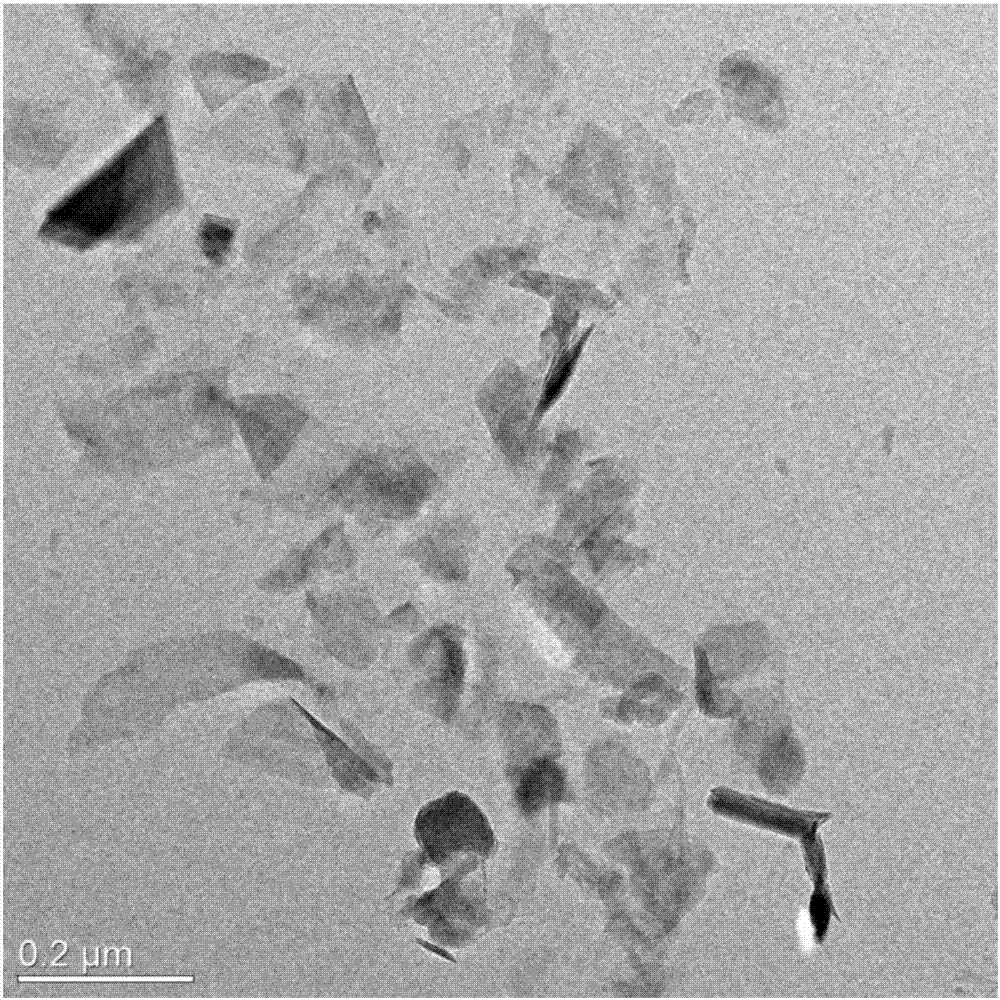

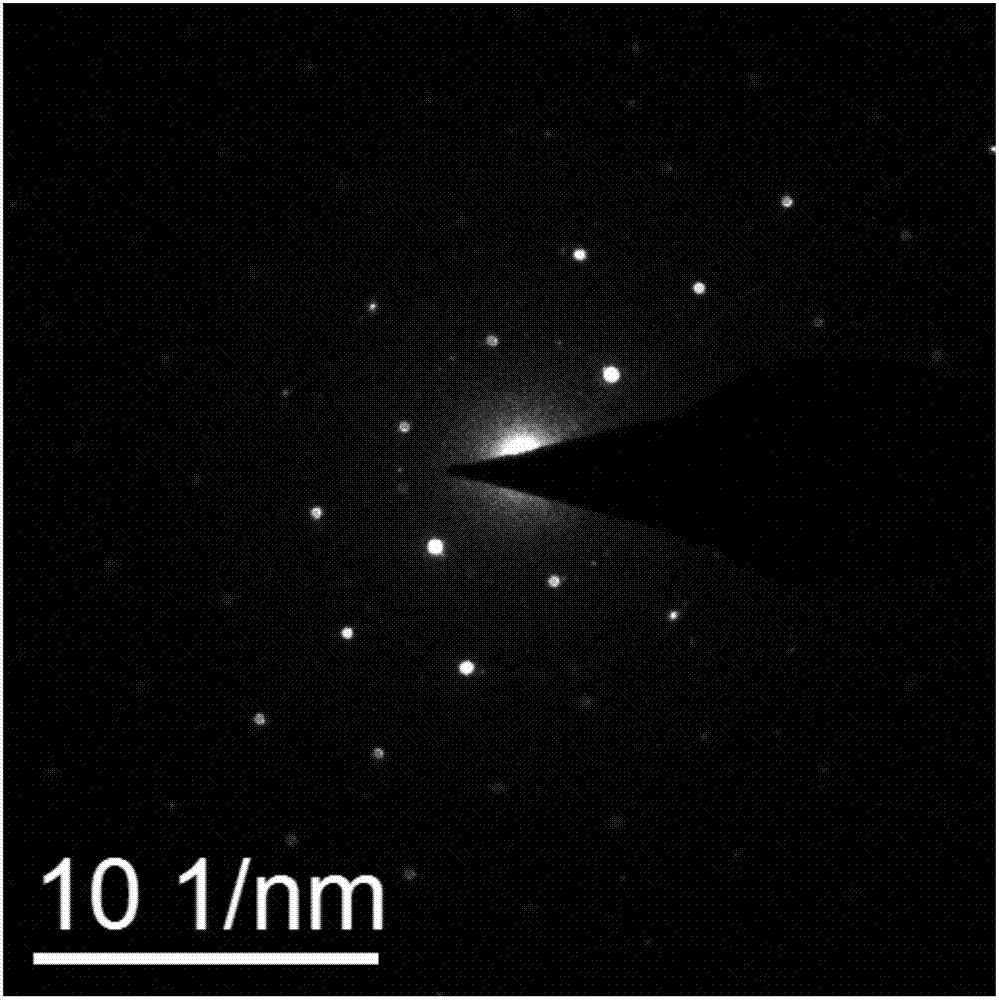

[0039] Embodiment 1 (preparation of molybdenum sulfide two-dimensional material)

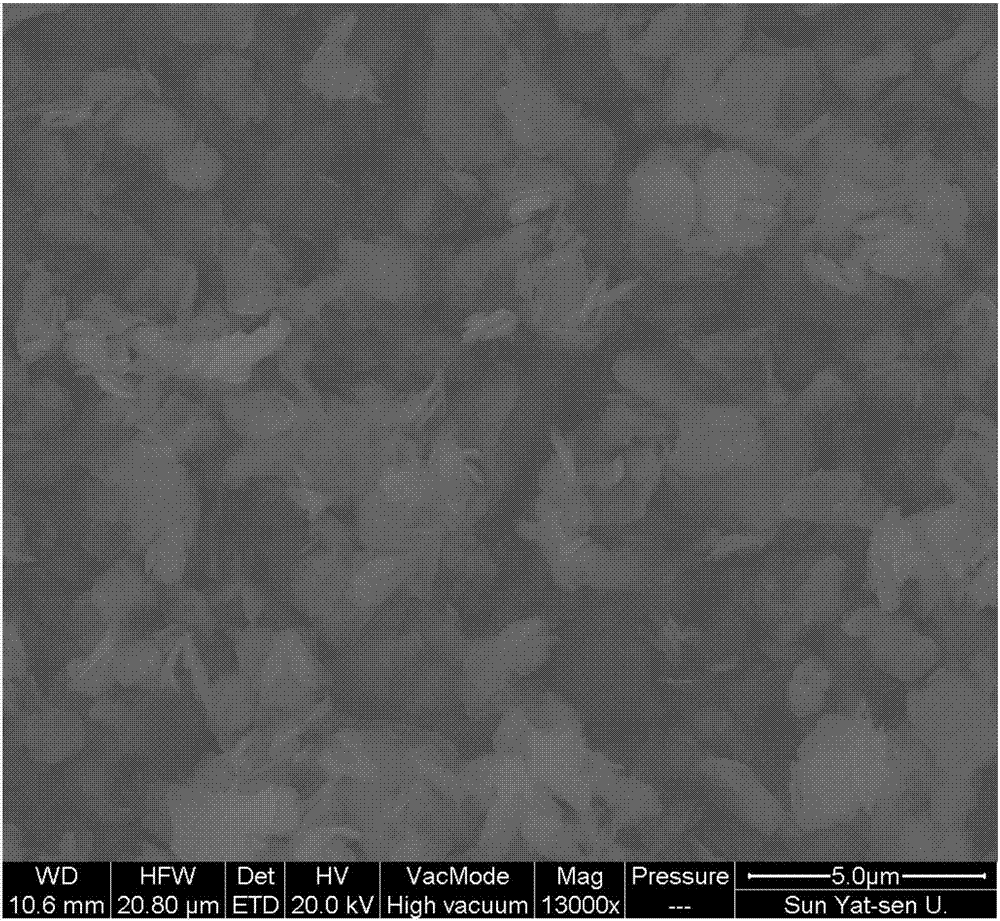

[0040] 1) molybdenum sulfide powder after 800 mesh sieves (see the morphology of powder figure 1 Shown) and lithium chloride were mixed according to the mass ratio of 5:1, then added to deionized water, and mixed evenly. Add the mixed liquid into the ball mill tank, select agate balls as the spherical film medium, select the size of the ball milling medium as 0.1mm, the range of the ball material ratio is 1:5, the ball milling speed is 200rpm to 500rpm, and the time is 1h.

[0041] 2) The product of the previous step is sieved to remove the ball milling medium. Then the residue was subjected to high-speed centrifugation, the centrifugation speed was 2000rmp, and the centrifugation time was 20 minutes. After the end, the upper liquid was removed, and the centrifuged sediment was repeatedly washed with alcohol and deionized water. The washed product was dried under vacuum environment.

[0042]...

Embodiment 2

[0045] Embodiment 2 (preparation of niobium selenide two-dimensional material)

[0046] 1) niobium selenide powder (see the morphology of powder Figure 5 Shown) and lithium chloride were mixed according to the mass ratio of 5:1, then added to deionized water, and mixed evenly. Add the mixed liquid into the ball milling tank, choose agate balls as the ball milling medium, the diameter of the agate balls is 0.2mm, the ratio of ball to material is 1:5, and the speed of ball milling is 300rpm. The time is 1h.

[0047] 2) The product of the previous step is sieved to remove the ball milling medium. Then the residue was subjected to high-speed centrifugation, the centrifugation speed was 3000rmp, and the centrifugation time was 20 minutes. After the end, the upper liquid was removed, and the centrifuged sediment was repeatedly washed with alcohol and deionized water. The washed product was dried under vacuum environment.

[0048] 3) Add the product in step 2 into the stripping...

Embodiment 3

[0051] Embodiment 3 (preparation of titanium sulfide two-dimensional material)

[0052] 1) Mix titanium sulfide powder and lithium chloride at a mass ratio of 5:1, then add to deionized water, and mix well. Add the mixed liquid into the ball mill tank, choose agate balls as the spherical film medium, select the size of the ball milling medium as 0.1mm, the range of the ball-material ratio is 1:5, the speed of the ball milling is 200rpm to 500rpm, and the time is 1h.

[0053] 2) The product of the previous step is sieved to remove the ball milling medium. Then the residue was subjected to high-speed centrifugation, the centrifugation speed was 3000rmp, and the centrifugation time was 20 minutes. After the end, the upper liquid was removed, and the centrifuged sediment was repeatedly washed with alcohol and deionized water. The washed product was dried under vacuum environment.

[0054] 3) Add the product in step 2 into the stripping liquid at a concentration of 1 g / L, and pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com