Preparation method of lithium battery cathode ultrathin nano material with high rate capability

A technology of nanomaterials and lithium batteries, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as irritation, highly toxic reactants, and differences in sample components, and achieve The operation is convenient and simple, the time used is short, and the effect of high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] First, in a 50 mL two-necked flask, 5 mL of oleylamine and 7 mL of octadecene were added, and 8 mmol of sulfur powder was dispersed in a mixed solvent of oleylamine and octadecene to obtain the precursor A of the sulfur source. Then, nitrogen gas was introduced to stir the solution A, and a mechanical pump was used to pump air. At the same time, the temperature was raised to 115° C., and the temperature was kept for 15 minutes. The air washing was repeated several times to obtain an oxygen-free environment. Add 4mmolTiCl 4 , under continuous stirring and a protective atmosphere, the temperature was raised to 295° C. and kept for 120 minutes to complete the growth of nanosheets, then the heating was stopped and cooled to room temperature. Finally, after centrifugation at 9000r / min, wash with ethanol and cyclohexane three times, discard the supernatant, and dry at 70°C for 30min to obtain a black powder, which is the target product.

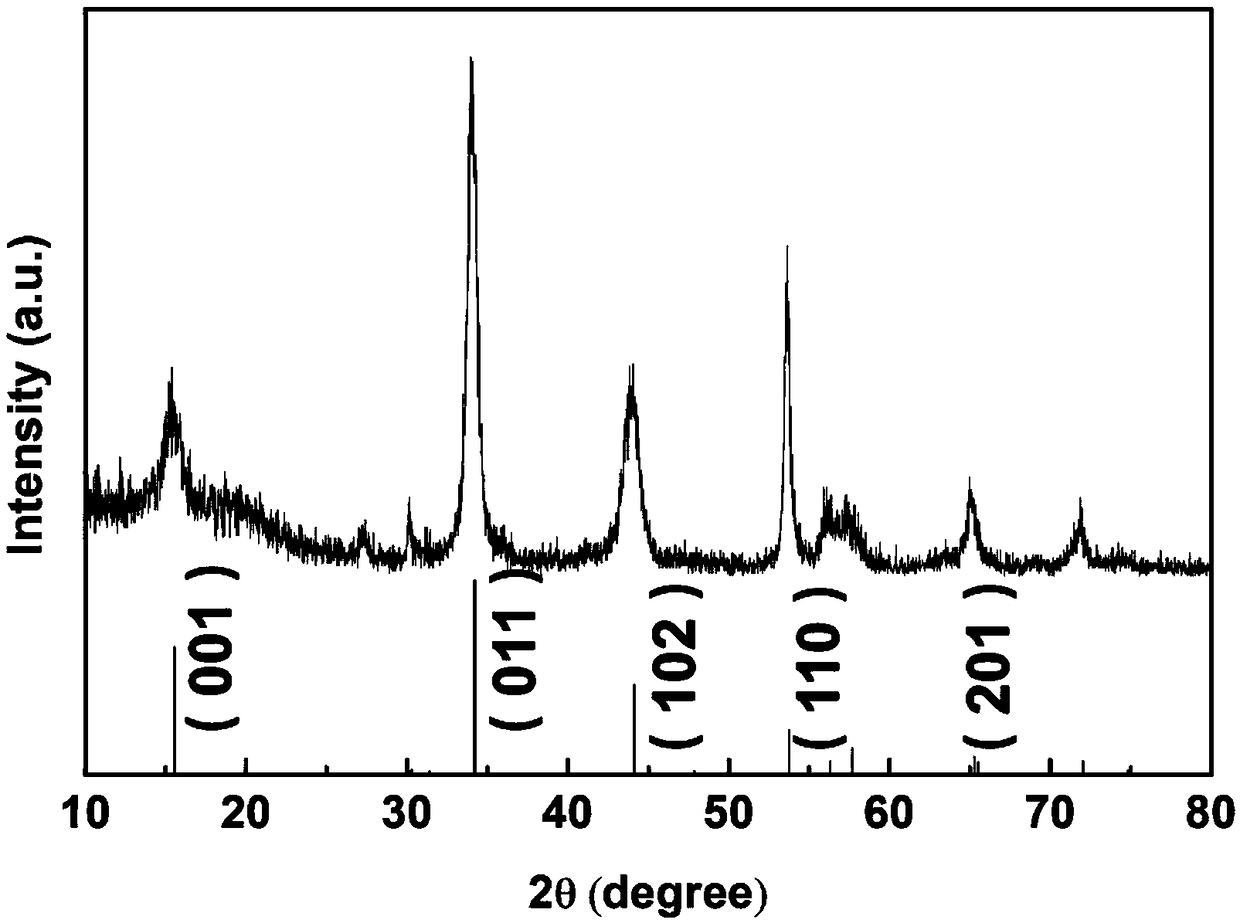

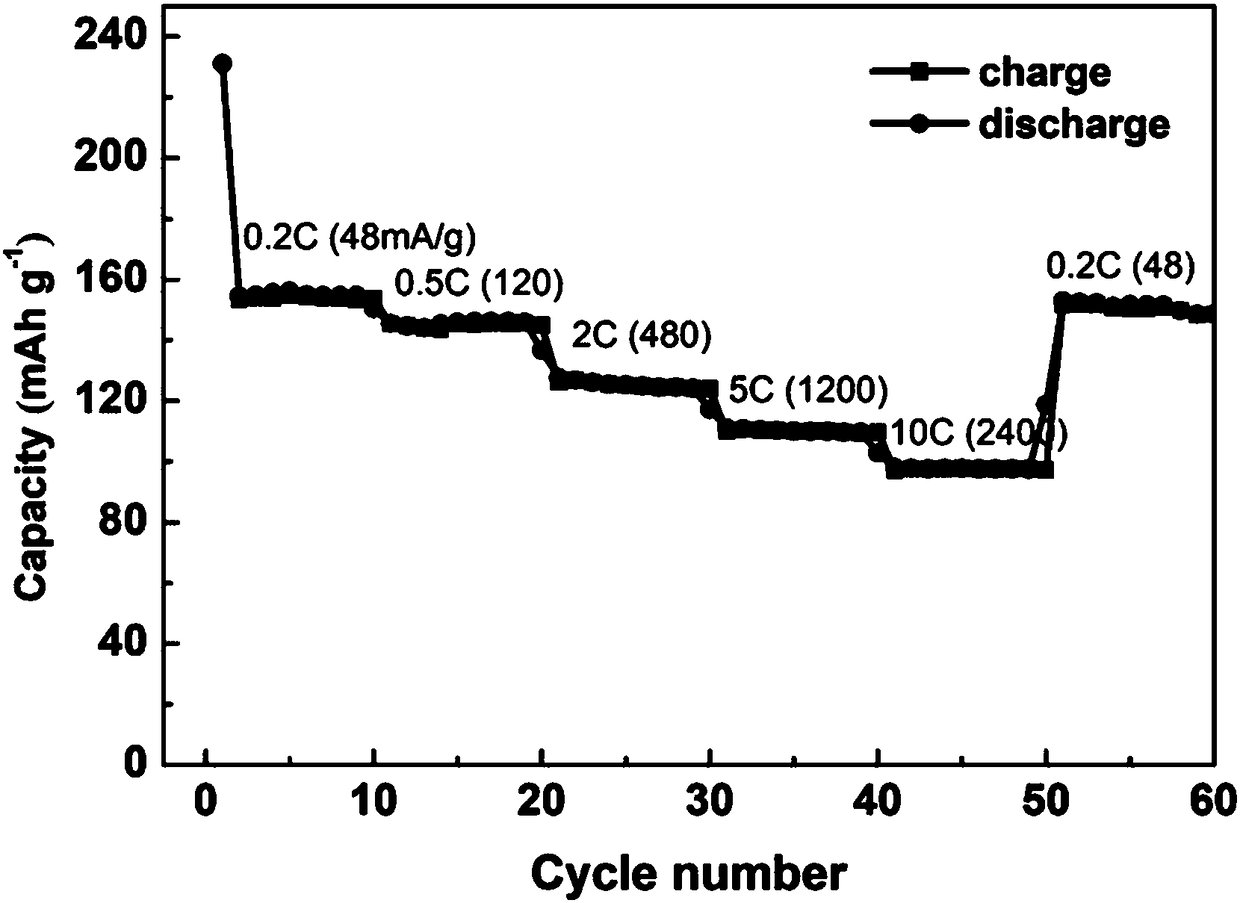

[0049] figure 1 It is the TiS grown...

Embodiment 2

[0053] First, in a 50 mL two-necked flask, 5 mL of oleylamine and 7 mL of octadecene were added, and 12 mmol of sulfur powder was dispersed into a mixed solvent of oleylamine and octadecene to obtain the precursor A of the sulfur source. Then, nitrogen gas was introduced to stir the solution A, and a mechanical pump was used to pump air. At the same time, the temperature was raised to 105° C., kept for 30 minutes, and gas washing was repeated several times to obtain an oxygen-free environment. Add 4mmolTiCl 4 , under constant stirring and a protective atmosphere, the temperature was raised to 310° C. and kept for 70 minutes to complete the growth of nanosheets, then the heating was stopped and cooled to room temperature. Finally, after centrifugation at 8000r / min, wash with ethanol and cyclohexane three times, discard the supernatant, and dry at 75°C for 45min to obtain a black powder, which is the target product.

[0054] Figure 4 It is the single crystal TiS grown accordi...

Embodiment 3

[0058] First, in a 50 mL two-necked flask, 5 mL of oleylamine and 7 mL of octadecene were added, and 2 mmol of sulfur powder was dispersed into a mixed solvent of oleylamine and octadecene to obtain the precursor A of the sulfur source. Then, nitrogen gas was introduced to stir the solution A, and a mechanical pump was used to pump air. At the same time, the temperature was raised to 135° C., and the temperature was kept for 15 minutes. The air washing was repeated several times to obtain an oxygen-free environment. Add 4mmolTiCl 4 , under continuous stirring and a protective atmosphere, the temperature was raised to 280° C., and the temperature was kept for 150 minutes to complete the growth of nanosheets, then the heating was stopped and cooled to room temperature. Finally, after centrifugation at 10000r / min, wash with ethanol and cyclohexane twice, discard the supernatant, and dry at 60°C for 30min to obtain a black powder, which is the target product.

[0059] Figure 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com