Preparation method of nano-material and mica composite multilayered structure

A nanomaterial, multi-layer structure technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems that have not yet been raised, and achieve the effect of easy mass preparation, convenient operation, and speeding up the research process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

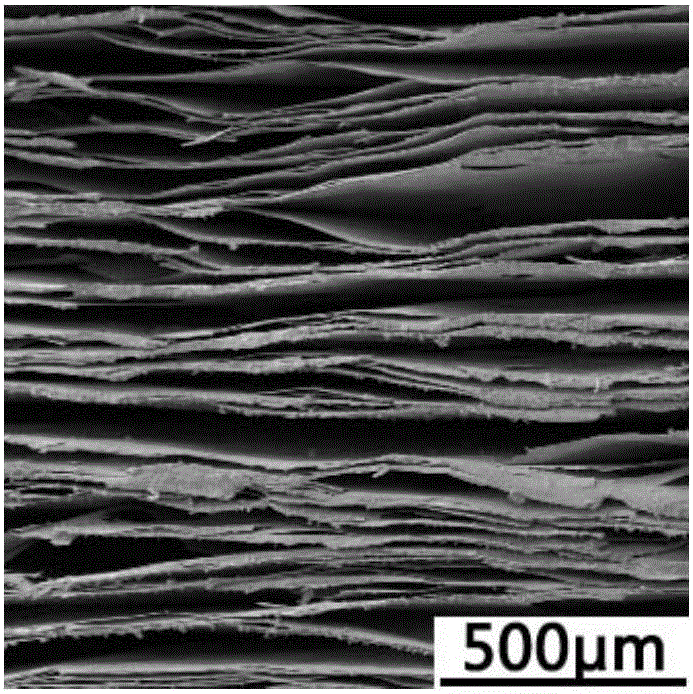

[0023] (1) Heat the phlogopite sheet in an annealing furnace to make it layered, the heating temperature is 700°C, and the heating time is 3h.

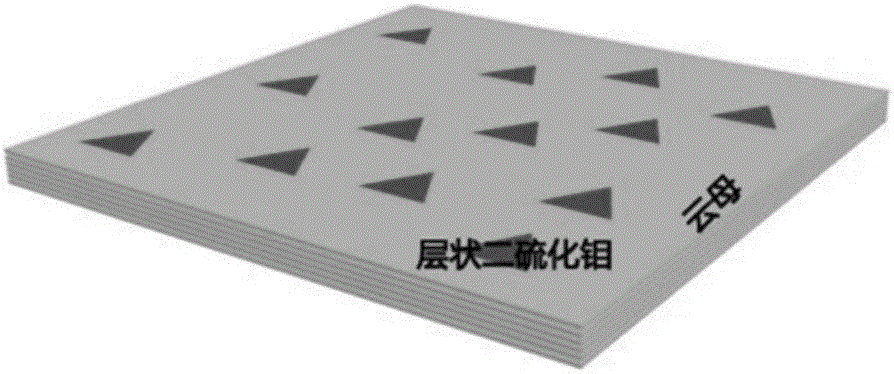

[0024] (2) Deposit MoO without difference in each layer of the layered mica sheet obtained in step (1) by means of vapor deposition 3 Thin layer material with a thickness of 2nm;

[0025] (3) MoO is all deposited on each layer of mica obtained in step (2) 3 The composite material of the thin-layer material is placed in a tube furnace, and sulfur powder is pushed in at high temperature to generate sulfur vapor for high-temperature gas-solid reaction to prepare layered MoS 2 Composite multilayer structure formed with mica.

Embodiment 2

[0027] (1) Heat the phlogopite sheet in an annealing furnace to make it layered, the heating temperature is 800°C, and the heating time is 1h.

[0028] (2) Utilize vapor deposition means to deposit TiO without difference in each layer of gaps in the layered mica sheets obtained in step (1) 2 Thin layer material with a thickness of 10nm;

[0029] (3) TiO is all deposited on each layer of mica obtained in step (2) 2 The composite material of the thin-layer material is placed in a tube furnace, and sulfur powder is pushed in at high temperature to generate sulfur vapor for high-temperature gas-solid reaction to prepare layered TiS 2 Composite multilayer structure formed with mica.

Embodiment 3

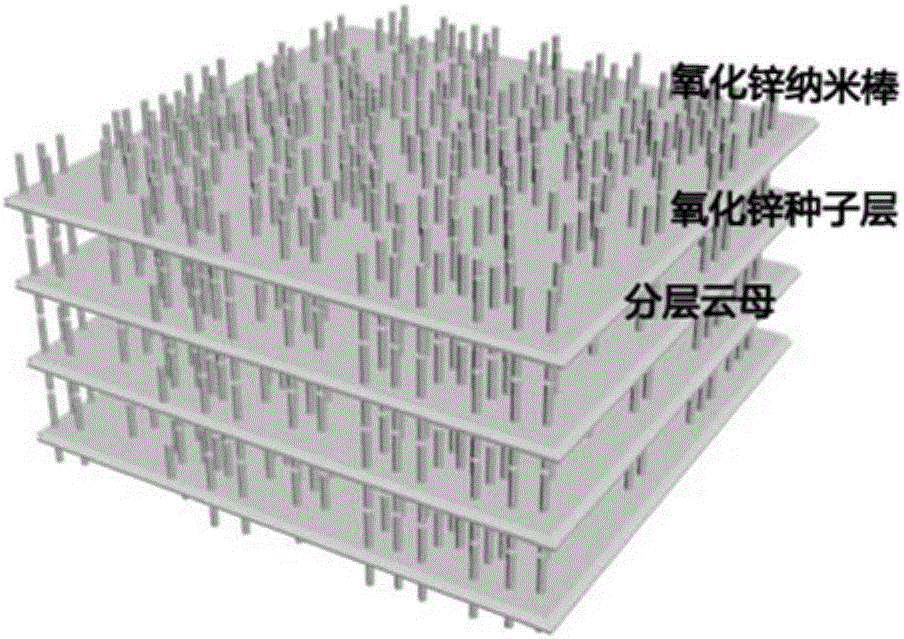

[0031] (1) Heat the phlogopite sheet in an annealing furnace to make it layered, the heating temperature is 600°C, and the heating time is 2h.

[0032] (2) Utilize vapor deposition means to deposit ZnO thin-layer material without difference in each layer of the gap of the layered mica sheet gained in step (1), with a thickness of 50nm;

[0033] (3) Put the composite material with ZnO thin layer material deposited on each layer of mica obtained in step (2) into a tube furnace, push in sulfur powder at high temperature to generate sulfur vapor to carry out high-temperature gas-solid reaction, and prepare a layer A composite multilayer structure formed of ZnS and mica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com