Two-dimensional material nanometer roll as well as preparation method and application thereof

A technology of two-dimensional materials and nanoscrolls, applied in nanotechnology, nanocarbon, and nanotechnology for materials and surface science, can solve the problems of lack of high-yield preparation methods, properties and application research obstacles, and achieve synthesis costs Low cost, short response time, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Fabrication of molybdenum disulfide nanoscrolls on silicon (surface-covered silica) substrates

[0088] (1) Preparation of ethanol aqueous solution: Measure 2 ml of ethanol and 1 ml of secondary water respectively, mix them, and prepare an ethanol aqueous solution with a volume ratio of 2:1.

[0089] (2) Preparation of molybdenum disulfide nanoscrolls: drop-coat the ethanol solution in (1) onto the surface of ultra-thin molybdenum disulfide deposited on the silicon substrate or immerse molybdenum disulfide in the aqueous solution, and take it out after 5 minutes.

[0090] (3) Preparation of composite molybdenum disulfide nanorolls: 1 nm-thick copper phthalocyanine was deposited on the surface of the ultra-thin molybdenum disulfide film by organic evaporation, and then soaked in ethanol aqueous solution in (1) for 30 minutes and then taken out.

[0091] Results Molybdenum disulfide nanorolls N1 and composite molybdenum disulfide nanorolls N2 loaded with copper phthalocya...

Embodiment 2

[0100] Fabrication of tungsten disulfide nanoscrolls on silicon substrates (surface covered with silica)

[0101] The same method as in Example 1 was used to prepare tungsten disulfide nanoscrolls, except that a methanol aqueous solution with a volume ratio of 5:1 was used.

[0102] Results Tungsten disulfide nanoscrolls N3 were prepared.

[0103] Morphological characterization of tungsten disulfide nanovolume N3:

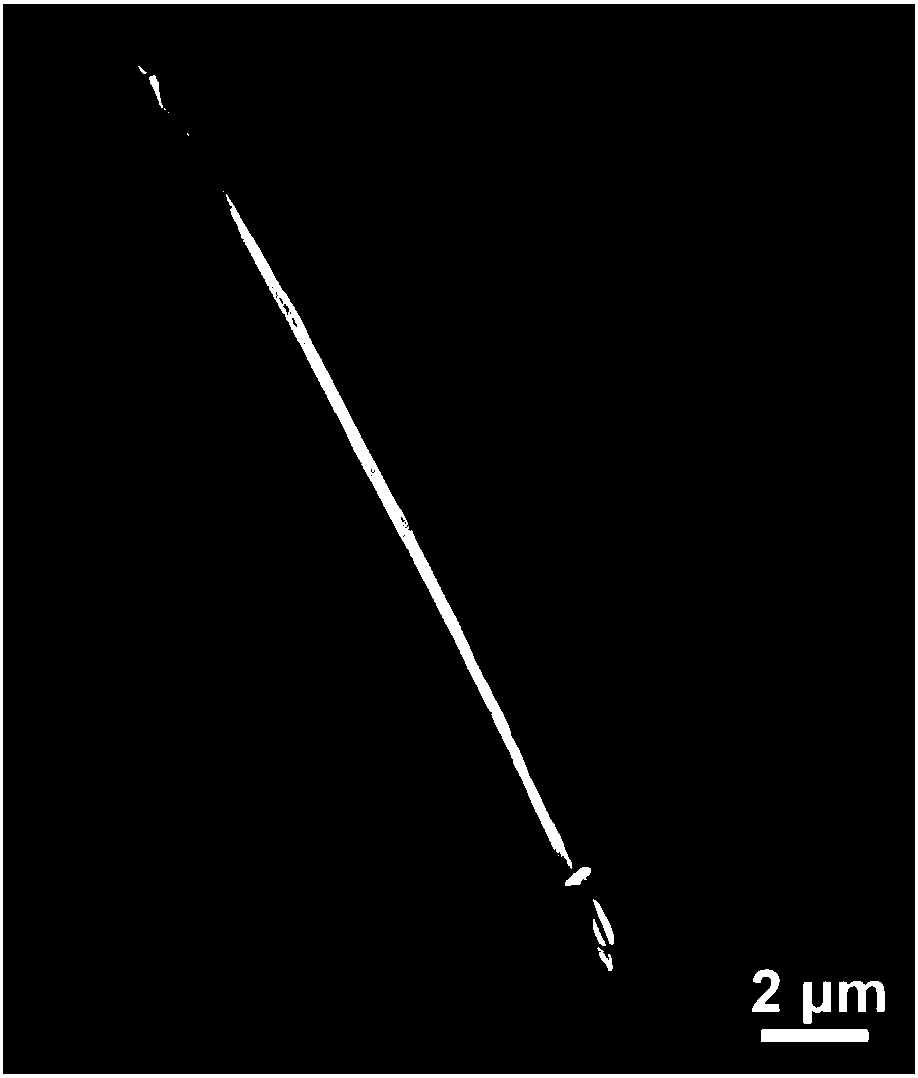

[0104] Figure 8 Scanning electron micrographs of the prepared tungsten disulfide nanorolls, it can be seen from the figure that the tungsten disulfide nanorolls have a rod-like, tightly coiled shape, with a length between 0.1-150 μm and an outer diameter of 10-500 nanometers Between, the diameter of the inner hollow layer is between 2-100nm.

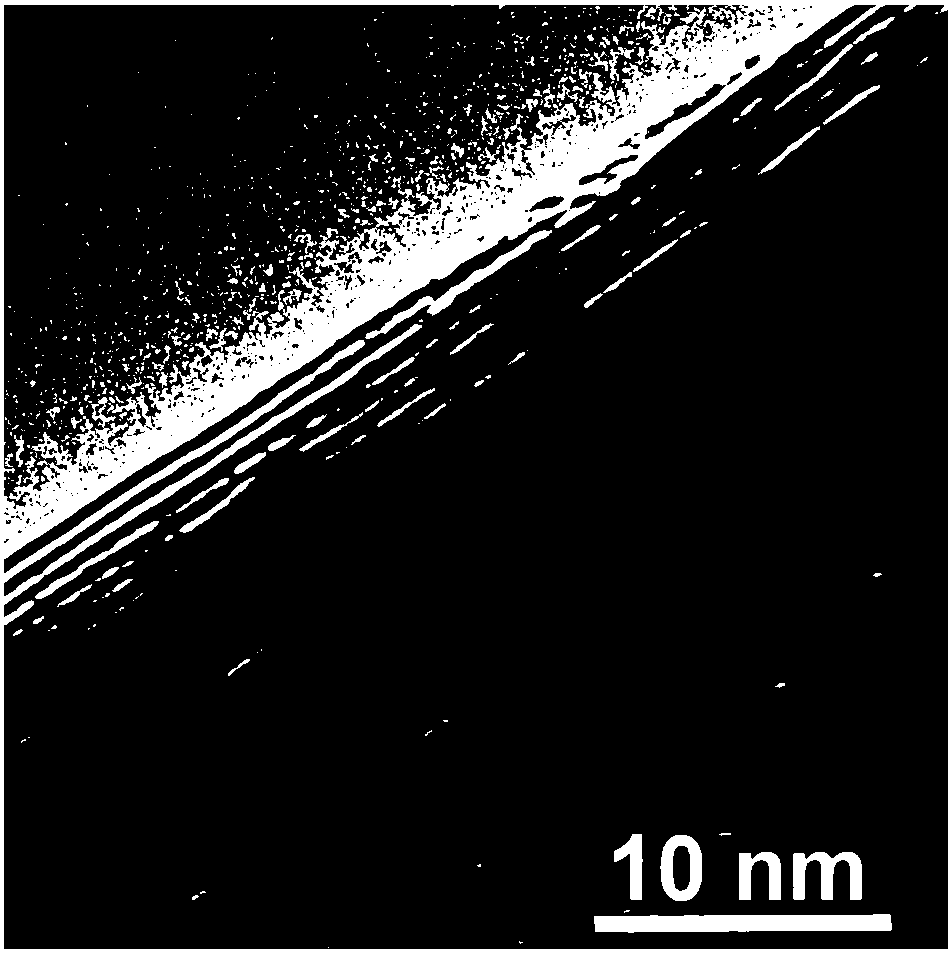

[0105] Figure 9 This is a high-resolution transmission electron micrograph of the prepared tungsten disulfide nanoscrolls, and the layer spacing is about 0.63 nm.

Embodiment 3

[0107] Fabrication of molybdenum diselenide nanoscrolls on a silicon substrate (surface covered with silicon dioxide)

[0108] The same method as in Example 1 was used to prepare tungsten disulfide nanoscrolls, except that an aqueous ethanol solution with a volume ratio of 3:1 was used.

[0109] Results Molybdenum diselenide nanoscrolls N4 were prepared.

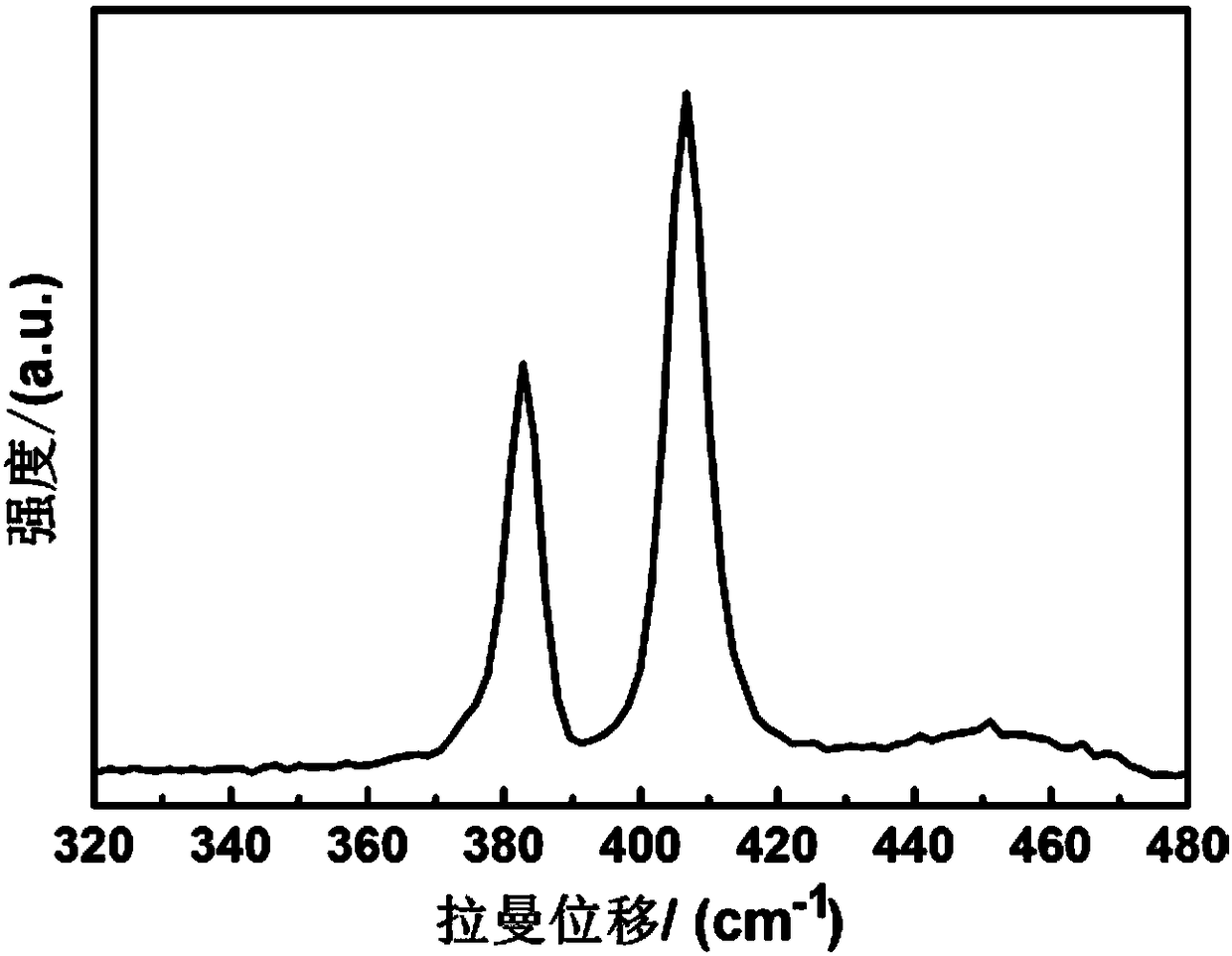

[0110] Morphological characterization of molybdenum diselenide nanovolume N4:

[0111] Figure 10 Scanning electron microscope photographs of molybdenum diselenide nano-rolls prepared for , it can be seen from the figure that the tungsten disulfide nano-rolls have a rod-like, tightly coiled shape, with a length between 0.1-100 μm and an outer diameter of 10-200 Between nanometers, the diameter of the inner hollow layer is between 5-60nm.

[0112] Figure 11 This is a high-resolution transmission electron micrograph of the prepared molybdenum diselenide nanoscrolls, with a layer spacing of about 0.65 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Layer spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com