Method for synthesizing titanium disulfide by mechanical ball milling

A technology of titanium disulfide and synthesis method, which is applied in the fields of titanium sulfide, chemical instruments and methods, inorganic chemistry, etc., which can solve the problems of low safety, danger, and time-consuming preparation, and achieve the effect of high operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

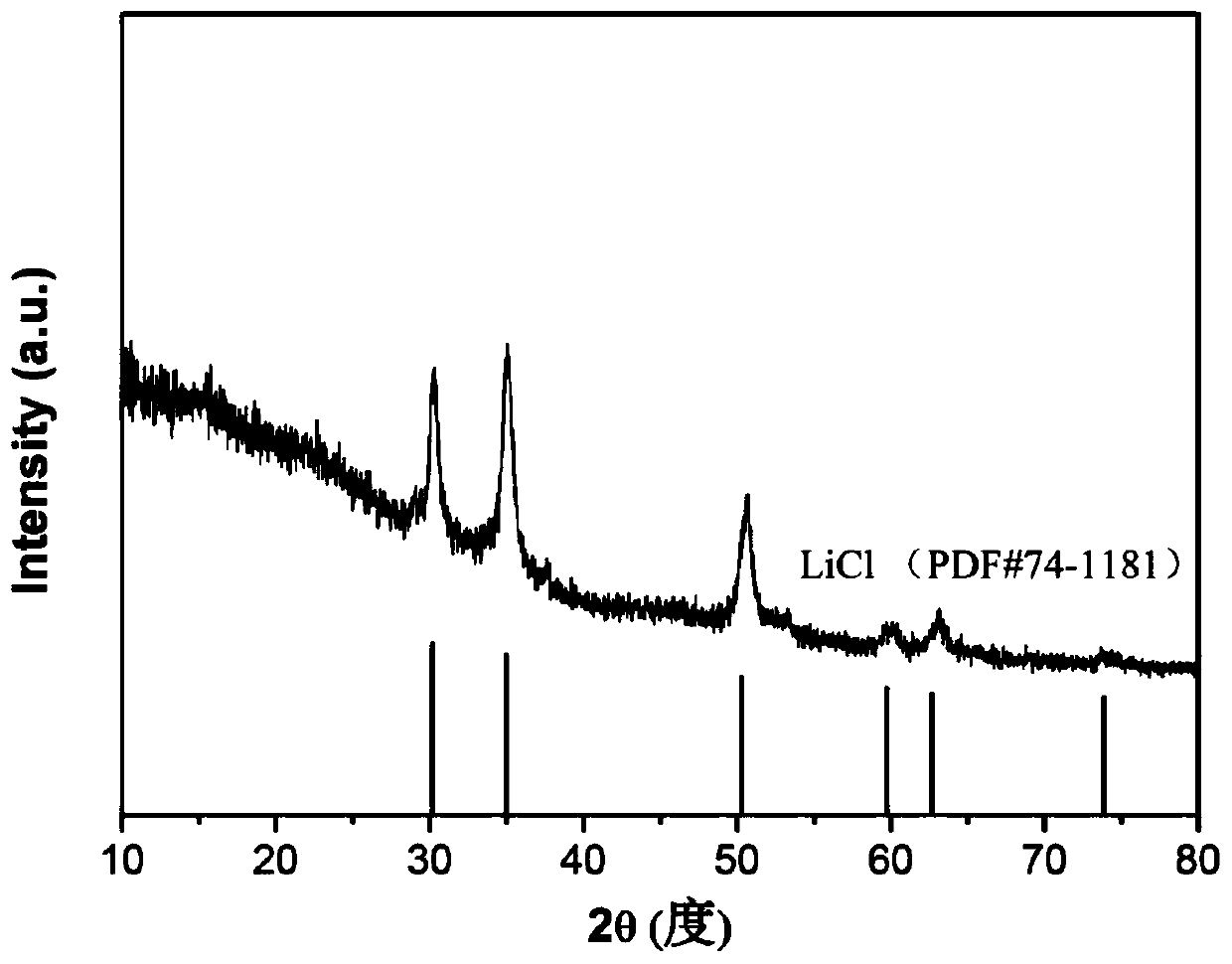

[0024] The lithium sulfide was dried in a vacuum oven at 100 °C for 12 h. Under the protection of an argon atmosphere, uniformly mix 0.65g of lithium sulfide and 0.78ml of titanium tetrachloride into a ball mill jar. The ratio of the total weight of grinding balls to the total weight of materials is 30:1. Under room temperature conditions, the ball milling tank was continuously ball-milled at a speed of 400r / min for 8 hours, and the obtained mixture of titanium disulfide and lithium chloride was then added with ethanol to wash and filter to separate the titanium disulfide, and after washing with water, put it in Titanium disulfide can be obtained after drying in an oven at 80°C. The XRD figure of embodiment 1 reaction generation product is as figure 1 shown.

Embodiment 2

[0026] Lithium sulfide was dried in a vacuum oven at 80 °C for 24 h. Under the protection of an argon atmosphere, uniformly mix 0.65g of lithium sulfide and 0.78ml of titanium tetrachloride into a ball mill jar. The ratio of the total weight of grinding balls to the total weight of materials is 50:1. Under room temperature conditions, the ball milling tank was continuously ball-milled at a speed of 350r / min for 12 hours to obtain a mixture of titanium disulfide and lithium chloride, and then the excess titanium tetrachloride was recovered by distillation, and finally ethanol was added to wash and filter the titanium disulfide It is separated, washed with water, and dried in an oven at 90°C to obtain titanium disulfide.

Embodiment 3

[0028] The lithium sulfide was dried in a vacuum oven at 70 °C for 36 h. Under the protection of an argon atmosphere, 0.65g of lithium sulfide and 1.56ml of titanium tetrachloride were uniformly mixed and added into a ball mill jar. The ratio of the total weight of grinding balls to the total weight of materials is 60:1. Under room temperature conditions, the ball milling tank was continuously ball-milled at a speed of 500r / min for 36 hours to obtain a mixture of titanium disulfide and lithium chloride, and then the excess titanium tetrachloride was recovered by distillation, and finally ethanol was added to wash and filter the titanium disulfide It is separated, washed with water, and dried in an oven at 85°C to obtain titanium disulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com