Method for preparing titanium disulfide crystal and product

A technology of titanium disulfide and crystals, which is applied in the field of efficient preparation of titanium disulfide crystals, can solve problems such as unclear safety, high reaction temperature, and many reaction steps, and achieve the effects of good repeatability, high purity, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

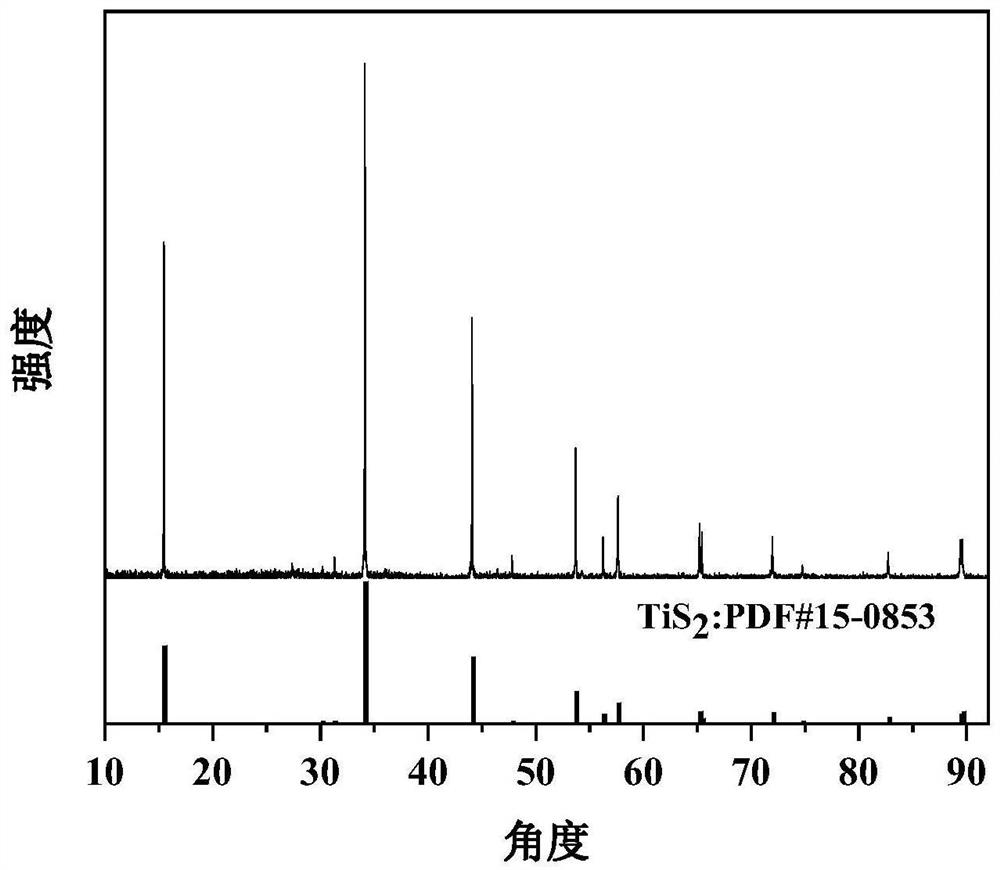

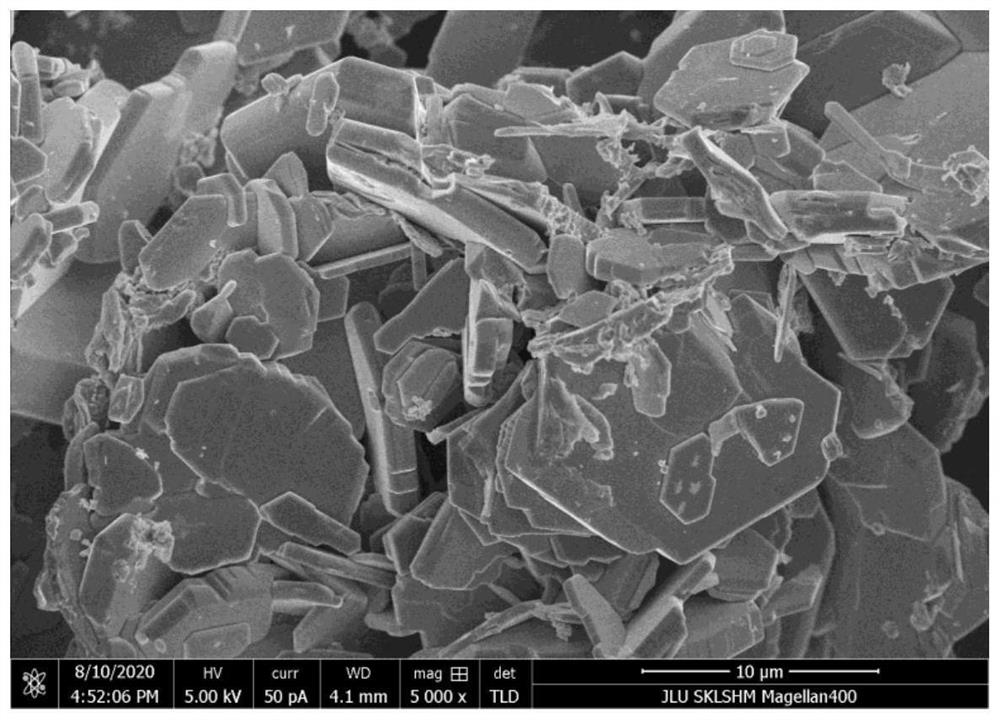

[0021] Embodiment 1 Optimal temperature prepares the whole process of titanium disulfide crystal

[0022] It uses titanium powder and sulfur powder as raw materials. First weigh 0.0032 mol of titanium powder, then weigh 0.0071 mol of sulfur powder; then weigh the weighed titanium powder and sulfur powder respectively, pack them in sealed bags, and finish loading the samples in the glove box Use SX-8307 1300 single-component ultra-high temperature structural adhesive to seal the quartz tube, and then place the sealed quartz tube under a baking lamp at 120°C for 4-6 hours. After the sealant is completely solidified, put it into the tube furnace at 600 ℃ for 48 hours. After the reaction is finished, wait for it to cool to room temperature, and a black powder sample can be obtained.

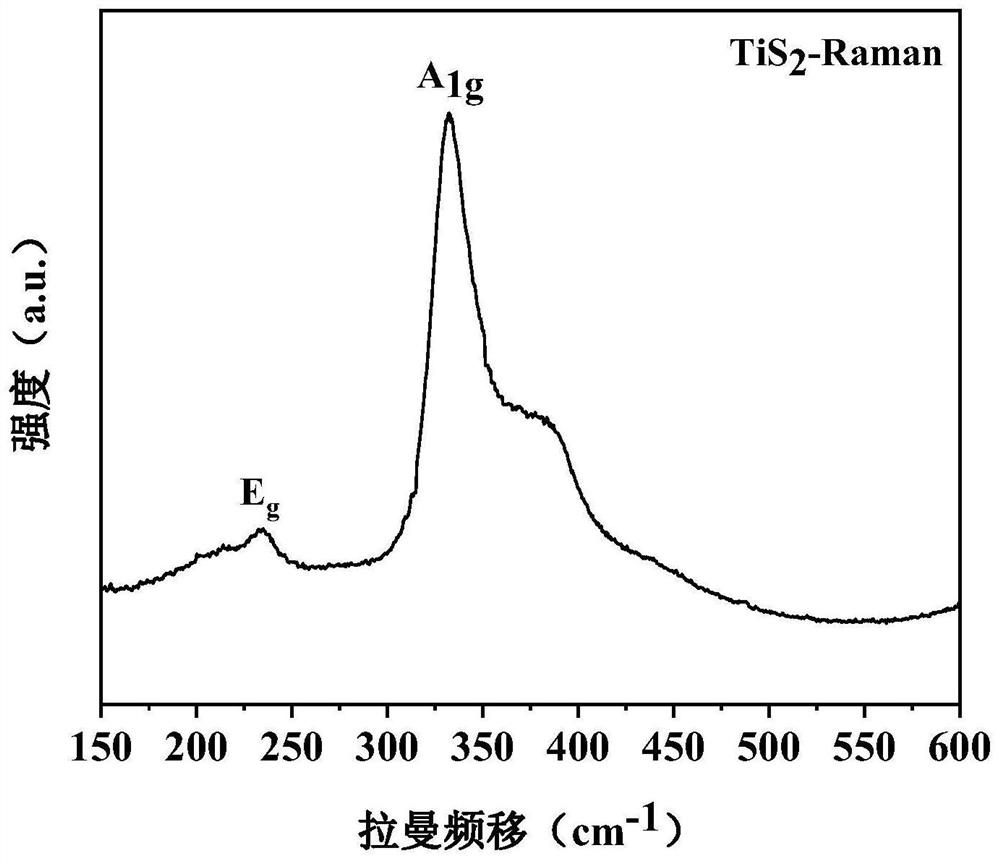

[0023] figure 1 The TiS prepared under the above conditions is given 2 The Raman spectrum of the crystal, where the Raman vibration mode: including E g Mode and A 1g mode, respectively located ...

Embodiment 2

[0024] Embodiment 2 prepares the whole process of titanium disulfide crystal at slightly lower temperature (counterexample)

[0025] It uses titanium powder and sulfur powder as raw materials. First weigh 0.0032mol of titanium powder, then weigh 0.0071mol of sulfur powder; then put the weighed titanium powder and sulfur powder into sealed bags, and use SX-8307 1300 single Component ultra-high temperature structural glue to seal the quartz tube, then place the sealed quartz tube under a 120°C oven lamp for 4-6 hours, and put it in a tube furnace for 48 hours at 550°C after the sealant is completely solidified . After the reaction is finished, wait for it to cool to room temperature, and a black powder sample can be obtained.

[0026] Figure 6 The XRD spectrum of the sample prepared under the above conditions is given, which proves that the crystallinity of the sample synthesized at 550°C is poor, the purity is low, and there is residual titanium after the reaction, which sh...

Embodiment 3

[0027] Example 3 The whole process of preparing titanium disulfide crystals with different reactant ratios

[0028] It uses titanium powder and sulfur powder as raw materials. First, according to the molar ratio of titanium to sulfur 2:3 (Ti:0.0042mol, S:0.0062mol); 1:2 (Ti: 0.0032mol, S:0.0071mol); 1:3 (Ti:0.0022mol, S:0.0069mol) ) Weigh the corresponding starting reactants; pack the weighed titanium powder and sulfur powder with weighing paper respectively and put them into sealed bags, complete the sample loading and sealing in the glove box and mark Ⅰ, Ⅱ, and In group III experiment, place the sealed quartz tube under a baking lamp at 120°C for 4-6 hours. After the sealant is completely solidified, put it into a tube furnace and keep it at the optimum temperature of 600°C for 48 hours. After the reaction is finished, wait for it to cool to room temperature, and a black powder sample can be obtained.

[0029] By drawing the XRD spectrum ( Figure 7 ), proving that the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com