Nano-sheet TiS2/Ti3C2TX MXene/C composite material as well as preparation method and application thereof

A composite material, nanosheet technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, can solve the problems affecting the cycle stability and high rate performance of MXene materials, and achieve excellent electrochemical sodium storage performance, high sodium storage Capacity, the effect of reducing cycle performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

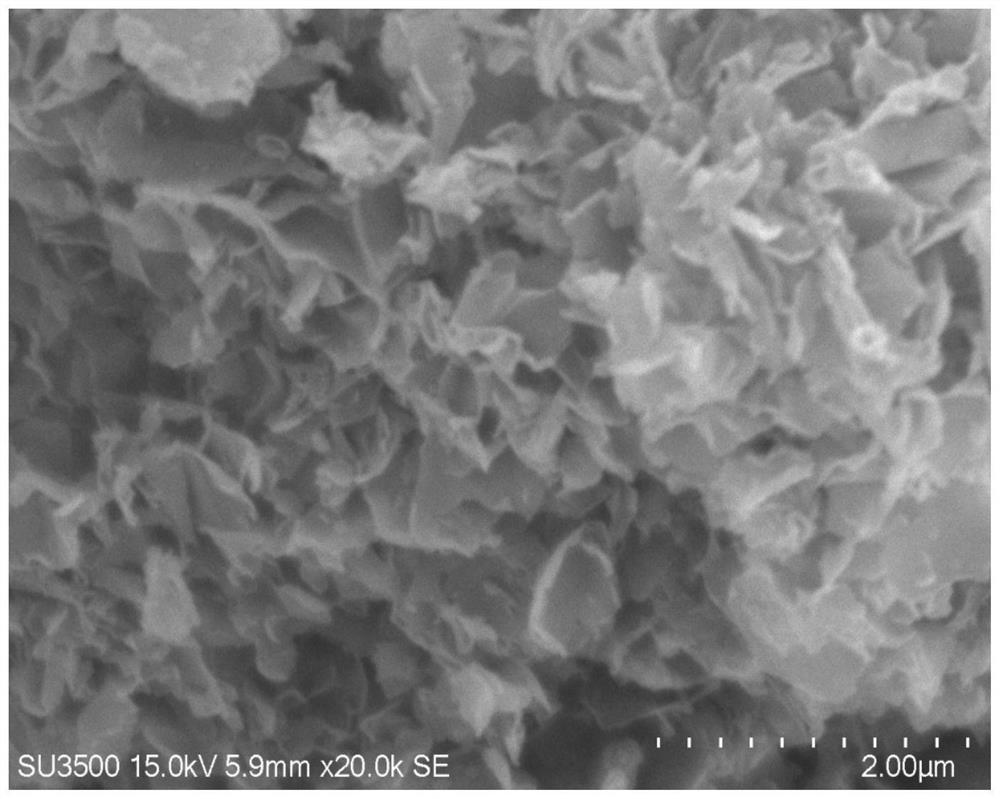

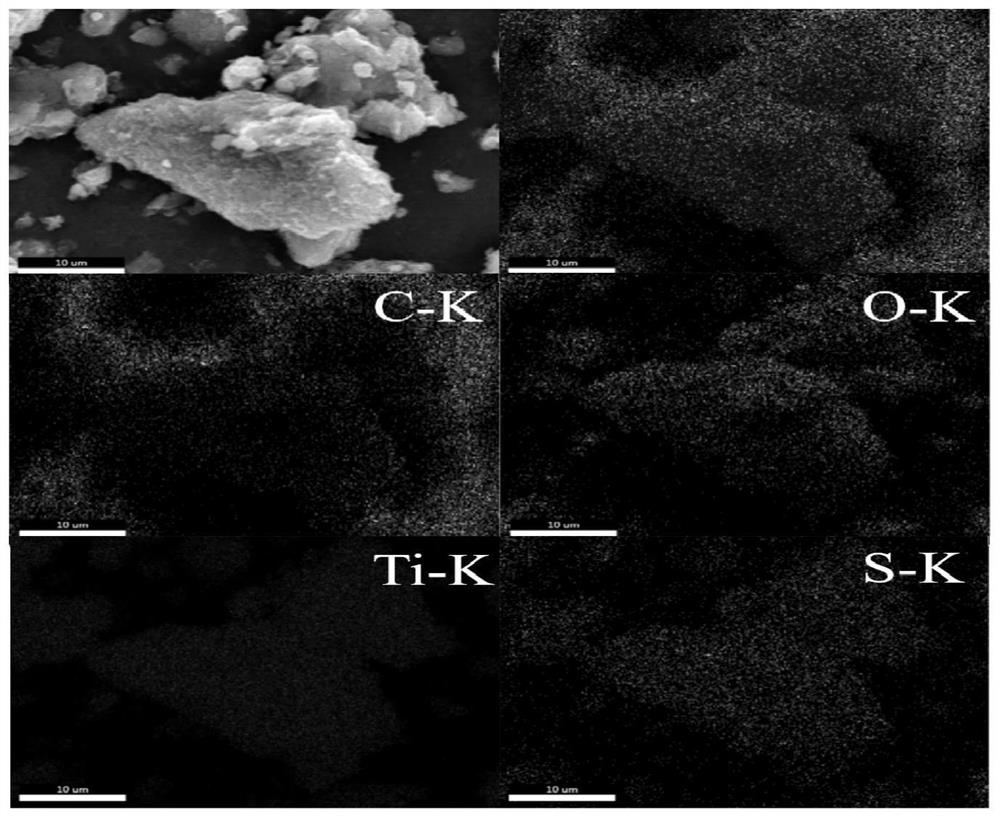

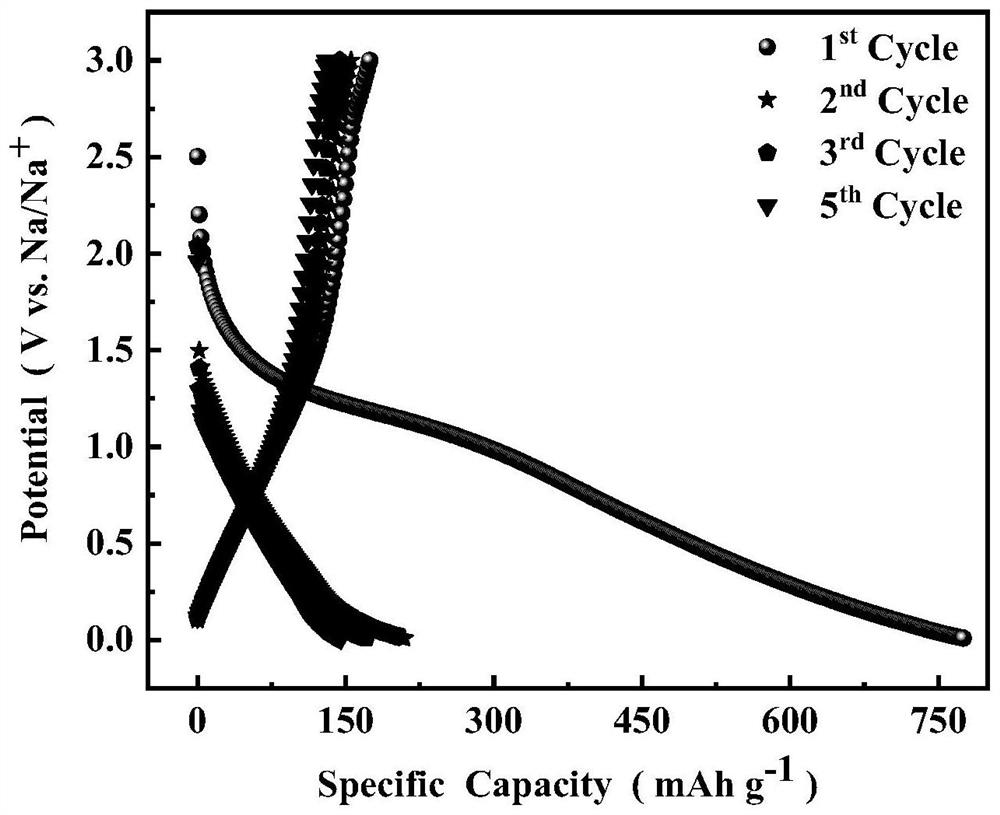

Image

Examples

Embodiment 1

[0027] (1) Disperse 2g LiF in 40mL HCl (9M) solution and stir for 30min to obtain a uniform and clear etching solution A;

[0028] (2) Weigh 2g Ti 3 AlC 2 The black powder was added to the etching solution A, under the heating condition of 45°C, the etching was stirred for 36 hours, and then centrifugally washed with deionized water for 5 times until the pH of the product was > 6, and a black clay-like precipitate B was obtained;

[0029] (3) Put the precipitate B in a 100mL beaker, then add 50mL of deionized water, perform ultrasonic stripping for 120min, centrifuge at 9000rpm for 30min, collect and take the upper black solution C;

[0030] (4) Take 15mL of the above solution C and place it in a 100mL beaker, add 35mL of deionized water, add 1.0g of dopamine hydrochloride, adjust the pH of the solution to 9 with ammonia water, stir for 12 hours, and centrifuge and wash at 4500rpm, and freeze-dry the precipitate to obtain gray powder D;

[0031] (5) Weigh 200 mg of the abov...

Embodiment 2

[0033] (1) Disperse 2g LiF in 40mL HCl (9M) solution and stir for 30min to obtain a uniform and clear etching solution A;

[0034] (2) Weigh 1g Ti 3 AlC 2 The black powder was added to the etching solution A, etched and stirred for 24 hours under the heating condition of 45°C, and then centrifuged and washed with deionized water for 5 times until the pH of the product was > 6, and a black clay-like precipitate B was obtained;

[0035] (3) Put the precipitate B in a 100mL beaker, then add 50mL of deionized water, perform ultrasonic stripping for 120min, centrifuge at 9000rpm for 30min, collect and take the upper black solution C;

[0036](4) Take 15mL of the above solution C and place it in a 100mL beaker, add 35ml of deionized water, add 1.0g of dopamine hydrochloride, adjust the pH of the solution to 9 with ammonia water, stir for 12h, and centrifuge and wash at 4500rpm, and freeze-dry the precipitate to obtain gray powder D;

[0037] (5) Weigh 200 mg of the above gray pow...

Embodiment 3

[0039] (1) Disperse 1g LiF in 20mL HCl (12M) solution and stir for 30min to obtain a uniform and clear etching solution A;

[0040] (2) Weigh 1g Ti 3 AlC 2 The black powder was added to the etching solution A, etched and stirred for 24 hours under the heating condition of 45°C, and then centrifuged and washed with deionized water for 5 times until the pH of the product was > 6, and a black clay-like precipitate B was obtained;

[0041] (3) Put the precipitate B in a 100mL beaker, then add 50mL of deionized water, perform ultrasonic stripping for 100min, centrifuge at 9000rpm for 30min, and collect the upper black solution C;

[0042] (4) Take 15mL of the above solution C and place it in a 100mL beaker, add 35mL of deionized water, add 1.0g of dopamine hydrochloride, adjust the pH of the solution to 9 with ammonia water, stir for 12 hours, and centrifuge and wash at 4500rpm, and freeze-dry the precipitate to obtain gray powder D;

[0043] (5) Weigh 200 mg of the above gray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com