Preparation method and application of carbon or transition metal doped iron-sulfur compound composite material

A technology of iron-sulfur compounds and transition metals, which is applied in the field of preparation of iron-sulfur compound composite materials, and can solve problems such as volume expansion, decay, and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Fe 2 o 3 / MoS 2 / FeS 2 Preparation of composite materials

[0037] (1) Add 45mL of ethylene glycol and 5mL of deionized water together and mix well;

[0038] (2) Add 1.2 mol iron acetylacetonate and 0.3 mol molybdenum acetylacetonate to the system in step (1), stir and sonicate evenly, pour it into a high-pressure reactor with polytetrafluoroethylene as the inner tank, heat at 150°C for 8 hours, and take it out Filter, wash the precipitate with ethanol, and finally dry it in an oven at 60°C for 12 hours;

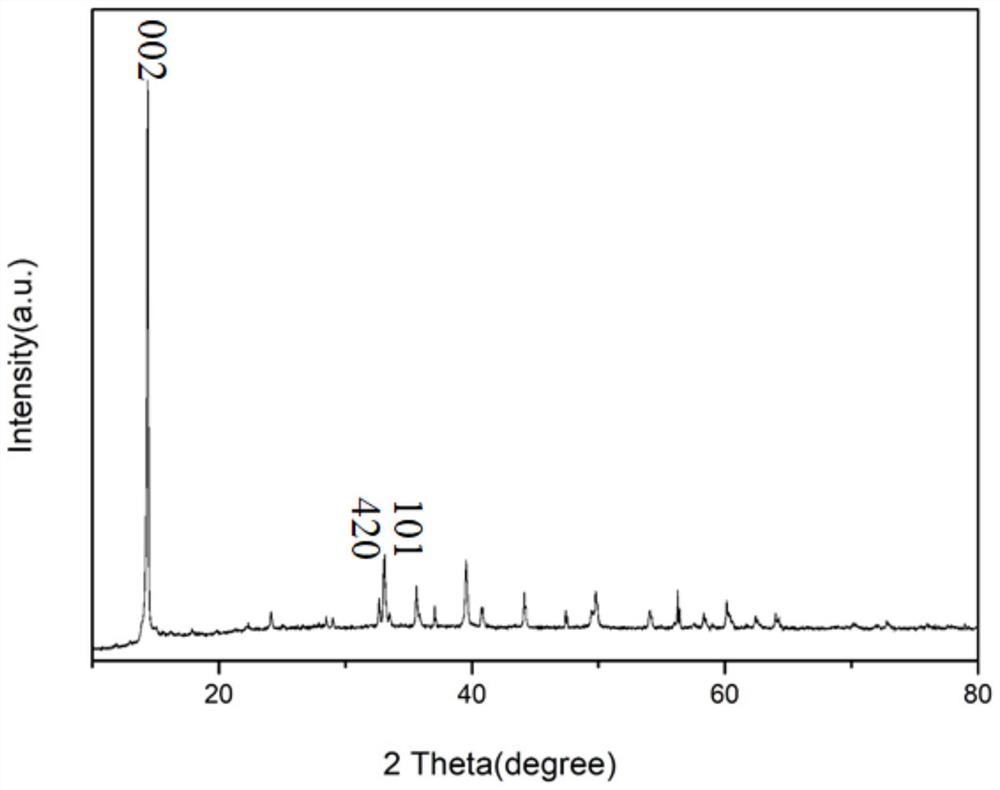

[0039] (3) The product of step (2) and 1.2 mol of sublimed sulfur were placed in an argon protective atmosphere and calcined at 450°C for 4 hours, and Fe was obtained after natural cooling. 2 o 3 / MoS 2 / FeS 2 composite material. The XRD pattern of the product is attached figure 1 shown, from the attached figure 1 The presence of Mo oxides (or hydroxides) was not detected in the composite materials, and it can be seen that the Mo in the composite material i...

Embodiment 2

[0055] Fe 2 o 3 / NiS / FeS composites

[0056] (1) Add 40mL of N-methylpyrrolidone and 5mL of deionized water together and mix well;

[0057] (2) Add 0.4 mol iron acetylacetonate and 0.08 mol nickel acetylacetonate to the system in step (1), stir and sonicate evenly, pour it into a high-pressure reactor whose inner tank is polytetrafluoroethylene, heat at 140°C for 10 hours, and take it out Filter, wash the precipitate with ethanol, and finally dry it in an oven at 70°C for 10 hours;

[0058] (3) The product of step (2) was calcined at 400°C for 6 hours in a sublimated sulfur atmosphere, and Fe was obtained after natural cooling. 2 o 3 / NiS / FeS composites.

[0059] Fe prepared by embodiment 2 2 o 3 / NiS / FeS composite material, acetylene black, and polytetrafluoroethylene are stirred and mixed at high speed in N-methylpyrrolidone at a mass ratio of 94:3:3 to fully obtain a slurry with a solid content of 66.22%. The slurry is coated on aluminum foil, then vacuum-dried at 1...

Embodiment 3

[0064] Fe 2 o 3 Preparation of / C / FeS composites

[0065] (1) Add 60mL of isopropanol and 6mL of ethylenediamine aqueous solution together and mix well;

[0066] (2) Add 0.4 mol iron acetylacetonate and 0.12 mol superconducting carbon black to the system of step (1), stir and ultrasonically evenly, pour it into a high-pressure reactor whose inner tank is polytetrafluoroethylene and heat at 135°C for 16 hours Take out and filter, wash the precipitate with ethanol, and finally dry it in an oven at 85°C for 7 hours;

[0067] (3) Mix and grind the product of step (2) with 1.2 mol of ferrous sulfide thoroughly, then place them together in a nitrogen protective atmosphere for calcination at 420°C for 6 hours, and obtain Fe after natural cooling. 2 o 3 / C / FeS composites.

[0068] Fe prepared by embodiment 3 2 o 3 / C / FeS composite material, superconducting carbon black, and polytetrafluoroethylene are stirred and mixed at high speed in N-methylpyrrolidone at a mass ratio of 7:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com