Negative electrode material, preparation method thereof and sodium ion battery

A negative electrode material and ion technology, applied in the fields of sodium ion batteries, negative electrode materials and their preparation, to achieve the effects of improving cycle stability, slowing down volume expansion, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The second aspect of the embodiment of the present application provides a method for preparing a negative electrode material, the preparation method comprising the following steps:

[0033] S01: dissolving the transition metal salt and nitrogen-containing sulfur source in a solvent, and performing drying treatment to obtain a precursor;

[0034] S02: Put the precursor and the selenium powder in the same container, and then calcinate to obtain the negative electrode material.

[0035] The composite material provided in the examples of the present application is synthesized by a one-step high-temperature solid-phase method, and the steps of the preparation method are simple and easy, and can be prepared in batches. Through this preparation method, the prepared transition metal sulfide can be doped with nitrogen ions and selenium ions at the same time, and by taking advantage of the advantages of the two anions of nitrogen and selenium, the capacity of the transition metal...

Embodiment 1

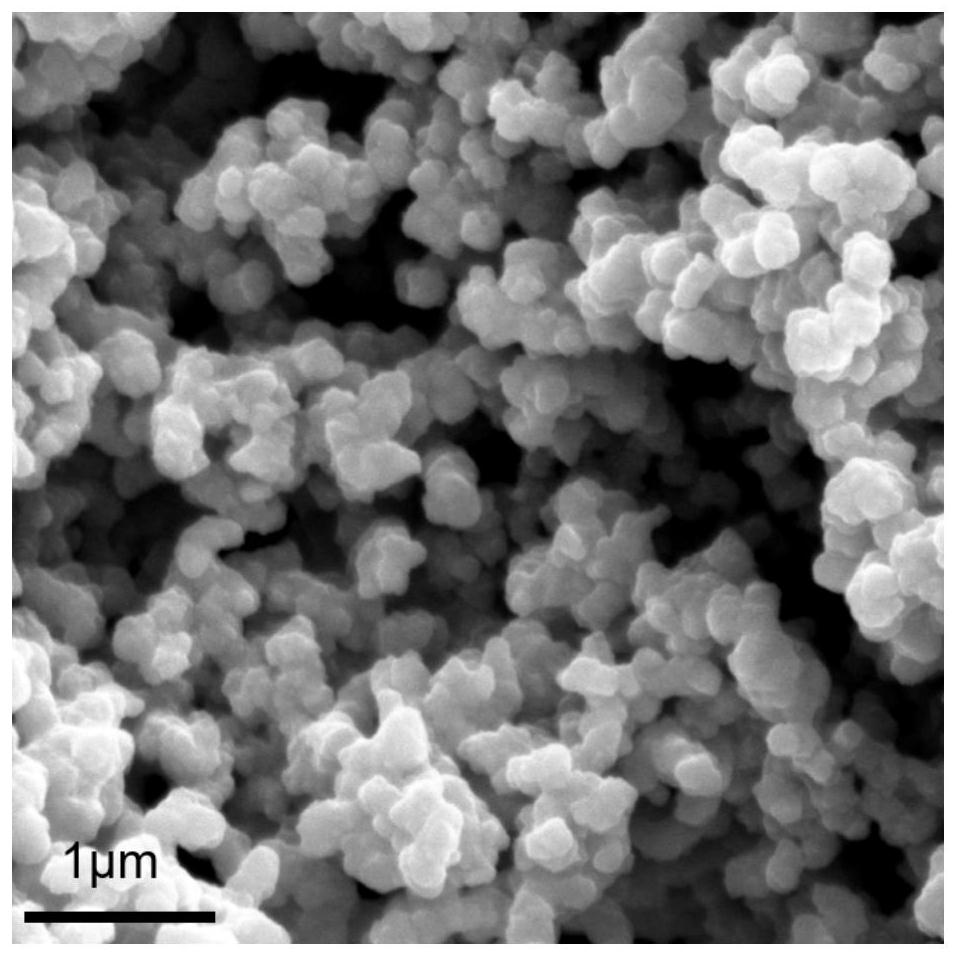

[0061] A nitrogen-selenium dianion doped Co 9 S 8 (N,Se-Co 9 S 8 ) preparation of negative electrode material

[0062] In this embodiment, cobalt chloride hexahydrate is used as the soluble metal salt, thiourea is used as the source of nitrogen and sulfur, the solvent is absolute ethanol, and the source of selenium is selenium powder. Concrete preparation process is as follows:

[0063] Add 1.9g of cobalt chloride hexahydrate and 0.37g of thiourea into 100mL of absolute ethanol, stir until a completely uniform solution is formed, then stir and evaporate to dryness under heating at 75°C, and dry the evaporated sample in a vacuum oven at 65°C After 24 hours, the precursor was obtained for use. Then grind the precursor into powder, put it into a porcelain boat and place it downstream of the tube furnace, then weigh 1g of selenium powder and put it into another porcelain boat and place it upstream of the tube furnace, then pass in argon as a protective gas, The heating rate ...

Embodiment 2-5

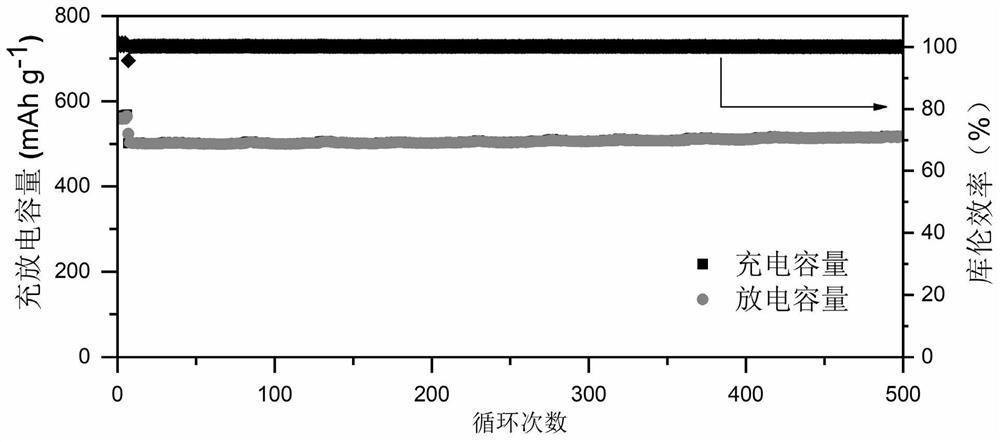

[0067] Cobalt sulfides with different valences prepared based on different amounts of thiourea

[0068] N in embodiment 2-5 and embodiment 1, Se-Co 9 S 8 The negative electrode preparation process steps are the same, the difference is that the raw material molar ratios of cobalt chloride hexahydrate and thiourea are different, and the raw material molar ratios used are respectively 1:4, 1:2.6, 1:2.3, 1:2, for example 2 The negative electrode material of -5 was tested for half-cell electrochemical performance, and compared with Example 1, the test results are shown in Table 1.

[0069] Table 1

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com