Highly ordered terminated MXene as well as preparation method and application thereof

A highly ordered and end-group technology, applied to structural parts, separators/films/diaphragms/spacer components, electrical components, etc., can solve the problem of being unable to achieve a high degree of ordering of a single group, and achieve high energy density And high security, high capacity and rate performance, the effect of suppressing puncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of highly ordered end-group MXene, comprising the following steps:

[0030] (1) 2g LiF was added to 40mL of 9M HCl which was stirred continuously, and 2g Ti was added to it 3 AlC 2 , and then put the above solution in a 40°C water bath and stirred for 24h to prepare MXene etched products, then washed with ultrapure water to pH 6, and then dried at 40°C for 24h to obtain MXene powder;

[0031] (2) The MXene powder in step (2) was made into a dispersion liquid of 10 mg / mL, and then ultrasonication was carried out at 300W power for 1 h with an ultrasonic crusher, and then centrifuged at 3500 r / min for 60 min, the upper dispersion liquid was collected, and then 20 mL of The upper dispersion liquid is suction filtered to obtain the MXene self-supporting membrane;

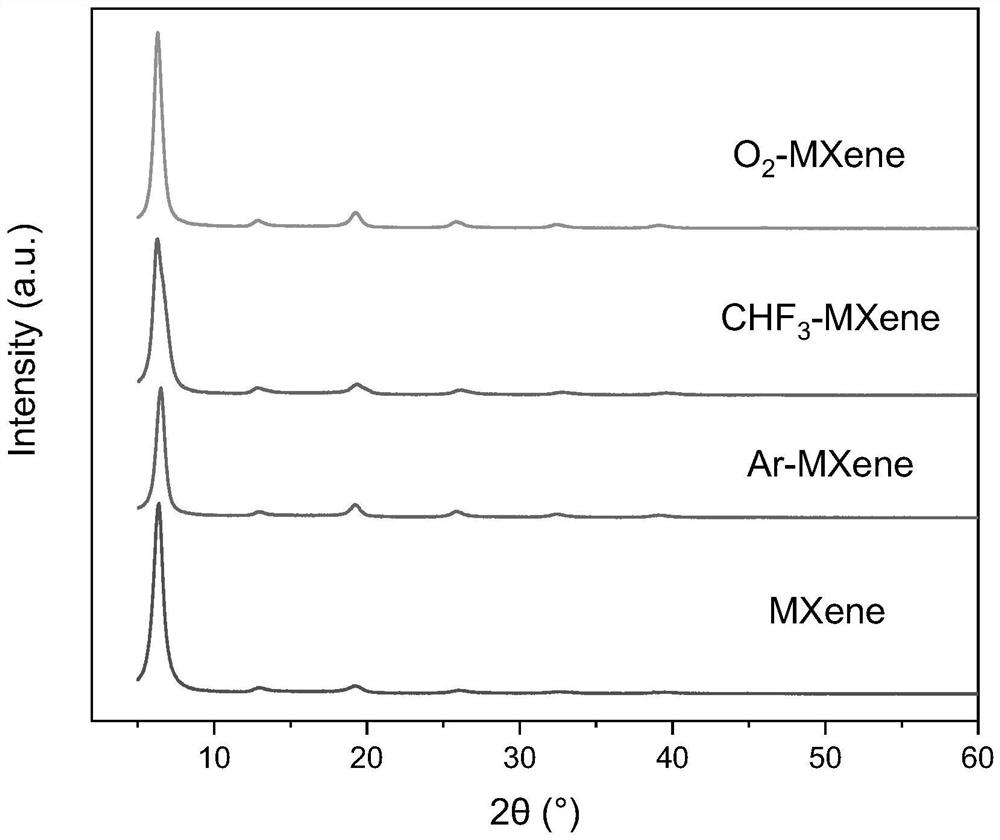

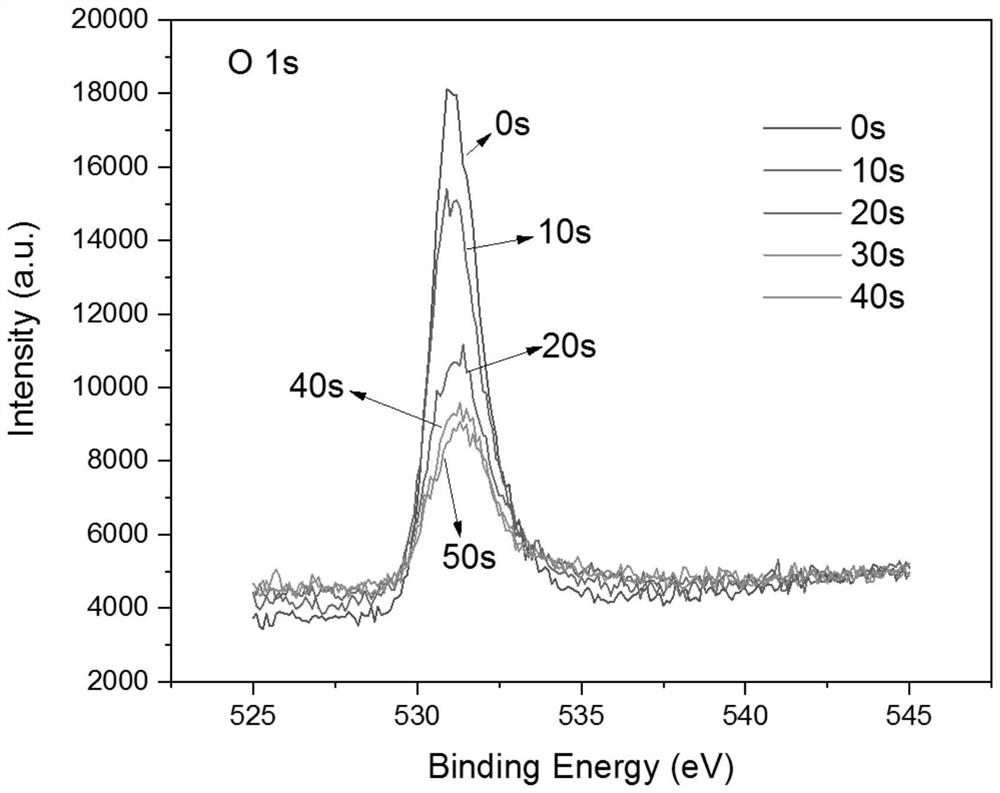

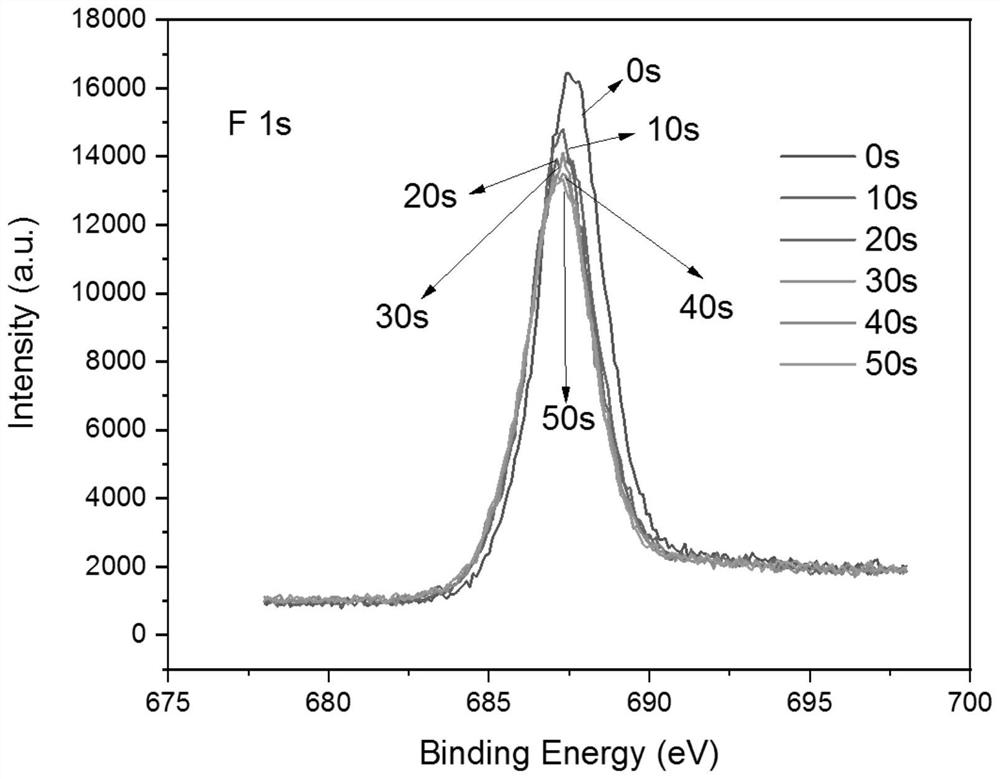

[0032] (3) performing plasma etching treatment on the MXene self-supporting film prepared in step (3), specifically: placing the prepared MXene self-supporting film in the chamber of an indu...

Embodiment 2

[0034] A preparation method of highly ordered end-group MXene, comprising the following steps:

[0035] (1) 2g LiF was added to 40mL of 9M HCl which was stirred continuously, and 2g Ti was added to it 3 AlC 2 , and then put the above solution in a 35°C water bath and stirred for 30h to prepare MXene etched products, then washed with ultrapure water to pH 6, and then dried at 35°C for 30h to obtain MXene powder;

[0036] (2) The MXene powder in step (2) was made into a dispersion liquid of 12 mg / mL, and then ultrasonication was carried out at 350W power for 1 h with an ultrasonic crusher, and then centrifuged at 3000 r / min for 70 min, the upper dispersion liquid was collected, and then 20 mL of The upper dispersion liquid is suction filtered to obtain the MXene self-supporting membrane;

[0037] (3) performing plasma etching treatment on the MXene self-supporting film prepared in step (3), specifically: placing the prepared MXene self-supporting film in the chamber of an indu...

Embodiment 3

[0039] A preparation method of highly ordered end-group MXene, comprising the following steps:

[0040] (1) 2g LiF was added to 40ml of 9M HCl which was stirred continuously, and 2g Ti was added to it 3 AlC 2 , and then put the above solution in a 45°C water bath and stirred for 20h to prepare MXene etched products, then washed with ultrapure water to pH 7, and then dried at 45°C for 20h to obtain MXene powder;

[0041] (2) The MXene powder in step (2) was made into a dispersion liquid of 10 mg / mL, and then ultrasonication was carried out at 400W power for 1 h with an ultrasonic crusher, and then centrifuged at 4000 r / min for 60 min, the upper dispersion liquid was collected, and then 20 mL of The upper dispersion liquid is suction filtered to obtain the MXene self-supporting membrane;

[0042] (3) performing plasma etching treatment on the MXene self-supporting film prepared in step (3), specifically: placing the prepared MXene self-supporting film in the chamber of an indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com