Patents

Literature

39results about How to "Lower diffusion barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

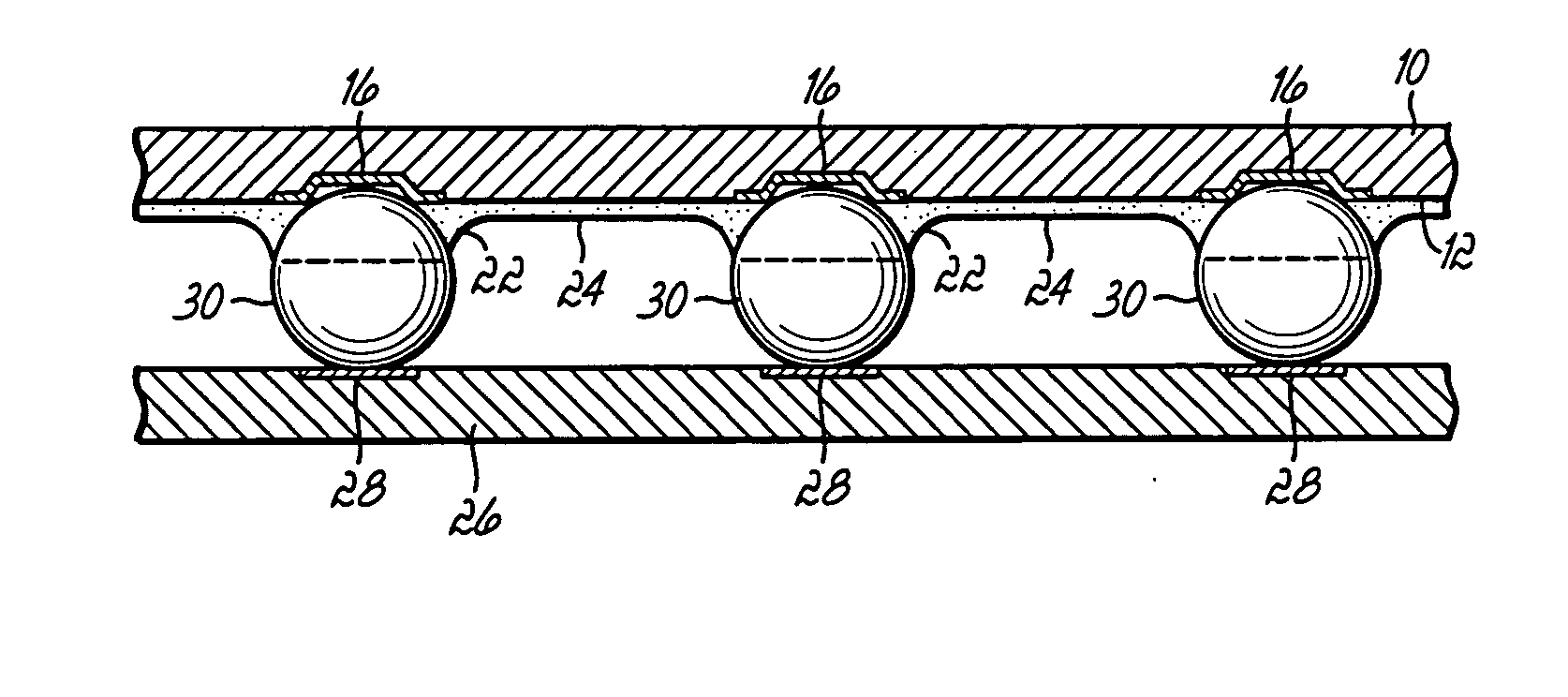

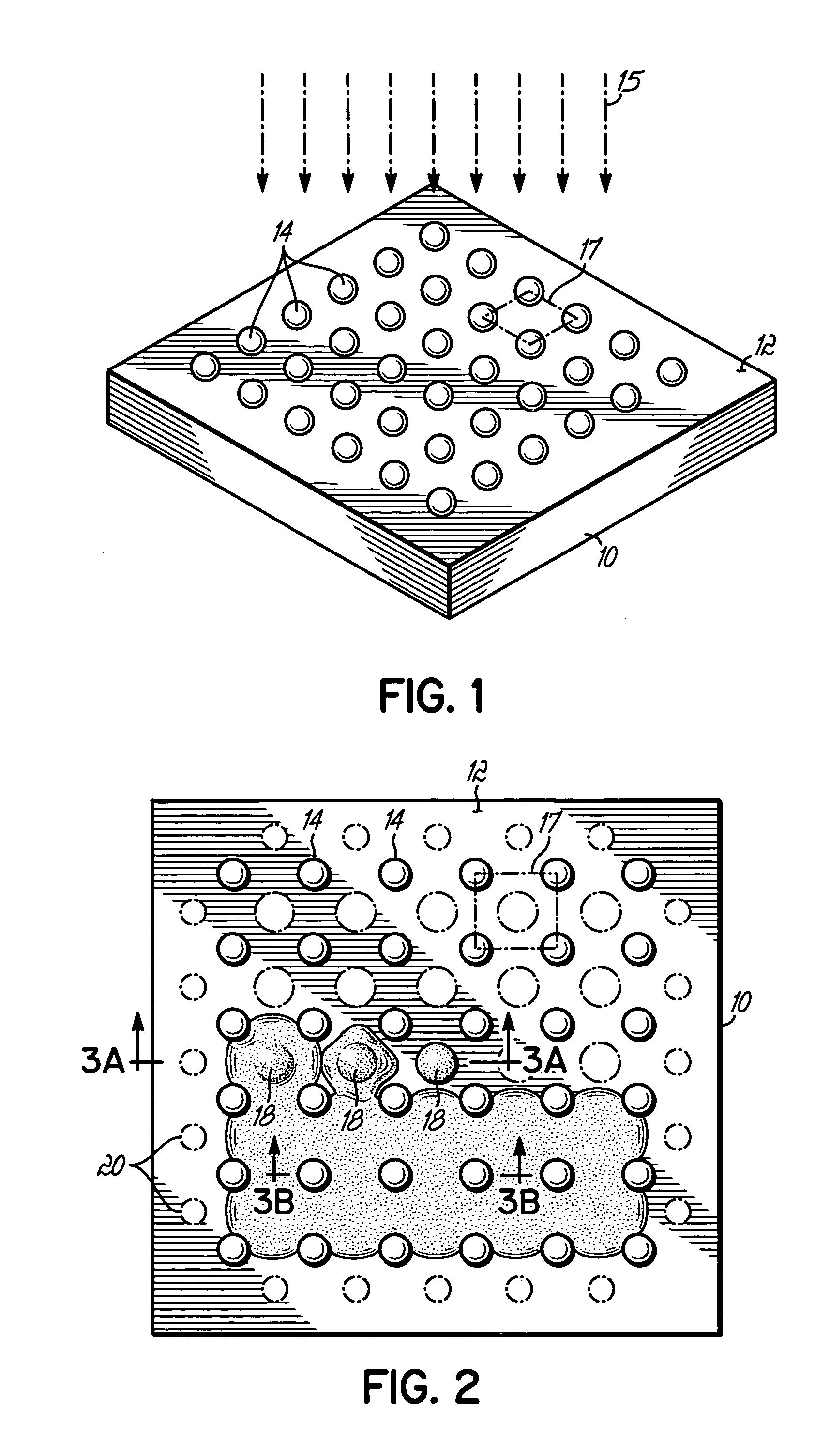

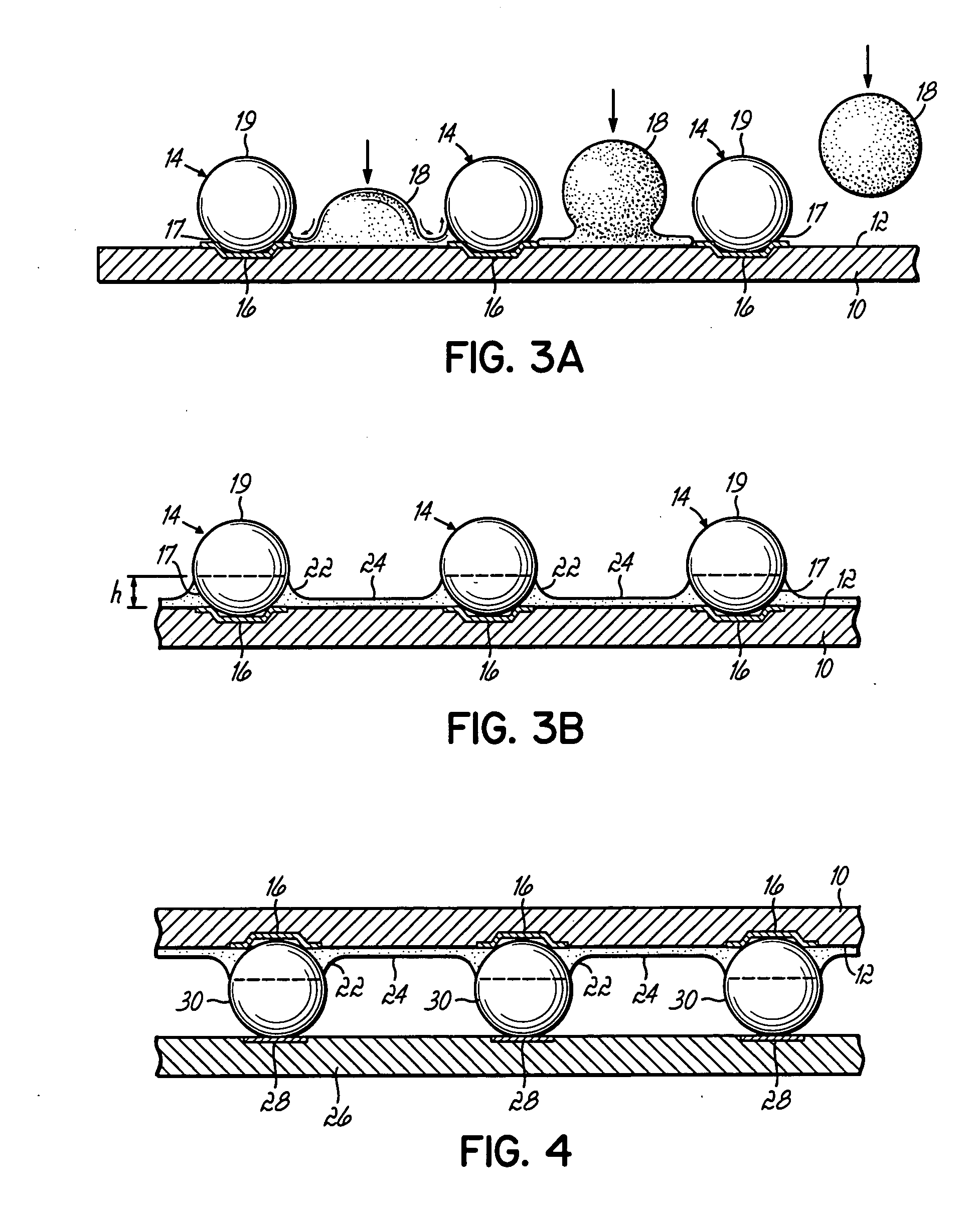

Method for preapplying a viscous material to strengthen solder connections in microelectronic packaging and microelectronic packages formed thereby

InactiveUS20050082670A1Excellent reworkabilitySimply removeSemiconductor/solid-state device detailsSolid-state devicesMetallurgyFilling materials

Apparatus and methods for preapplying discrete amounts of underfill material of a component on a component substrate before the solder bumps of the component are joined by reflow with a packaging substrate to create a microelectronics package. The underfill material is preferably applied by a noncontact dispensing technique as discrete amounts at interstitial areas on an active surface of the component substrate defined between nearest-neighbor solder bumps. The underfill material forms a continuous meniscus of underfill material across the interstitial areas not occupied by the solder bumps and forms a collar encircling each of the solder bumps. The cured underfill material strengthens and improves the reliability of the solder joints formed by the bump reflow.

Owner:NORDSON CORP

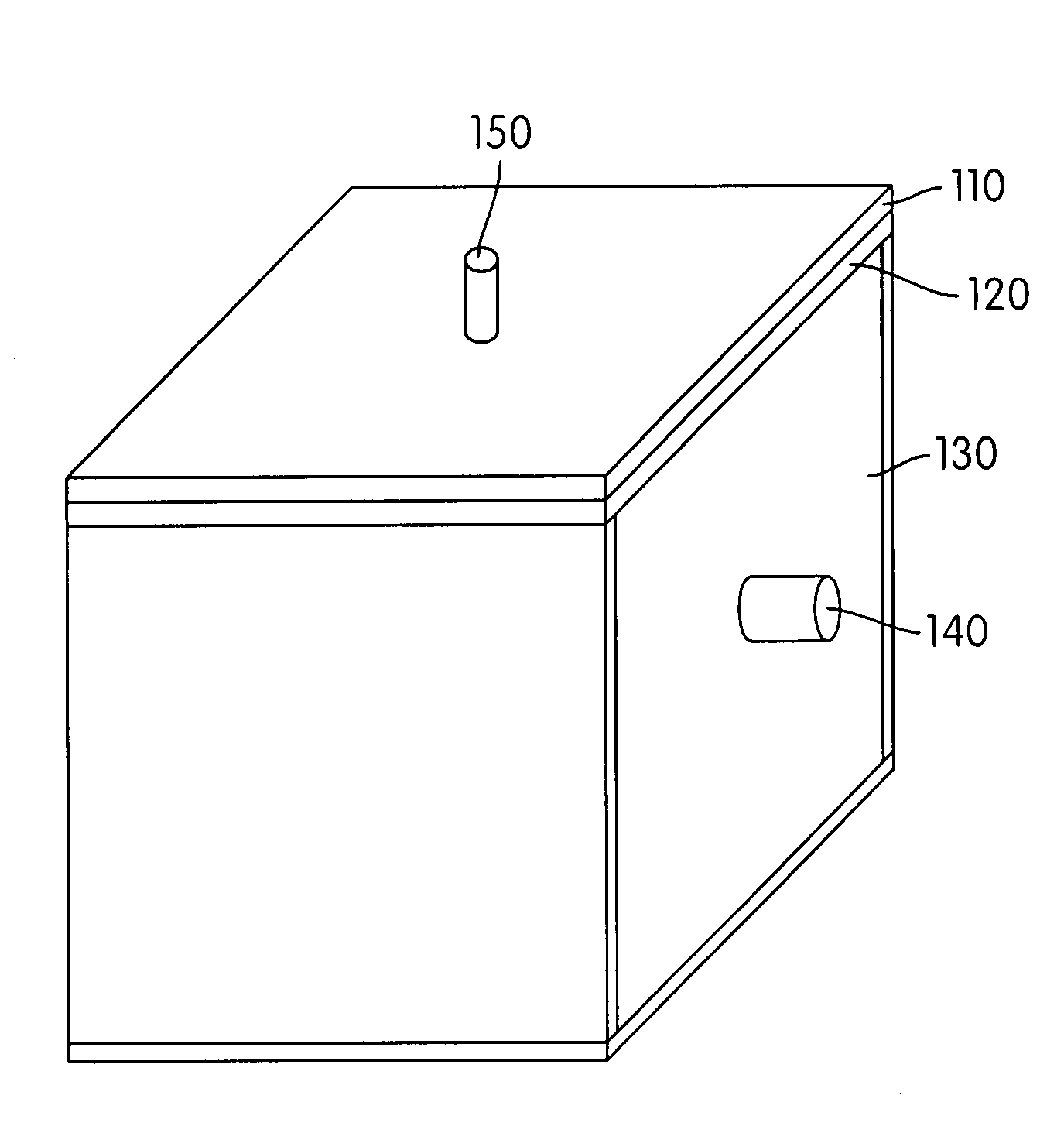

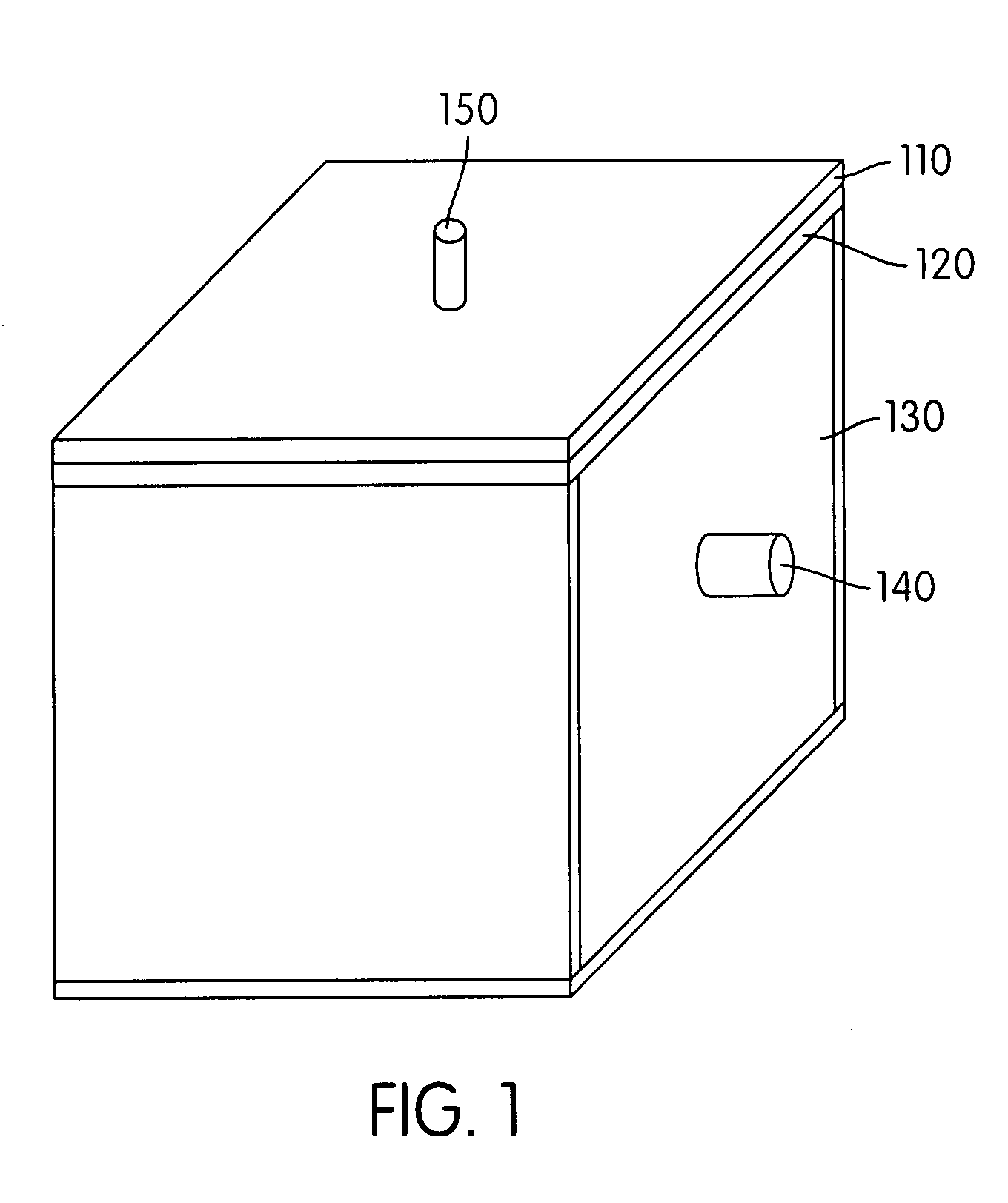

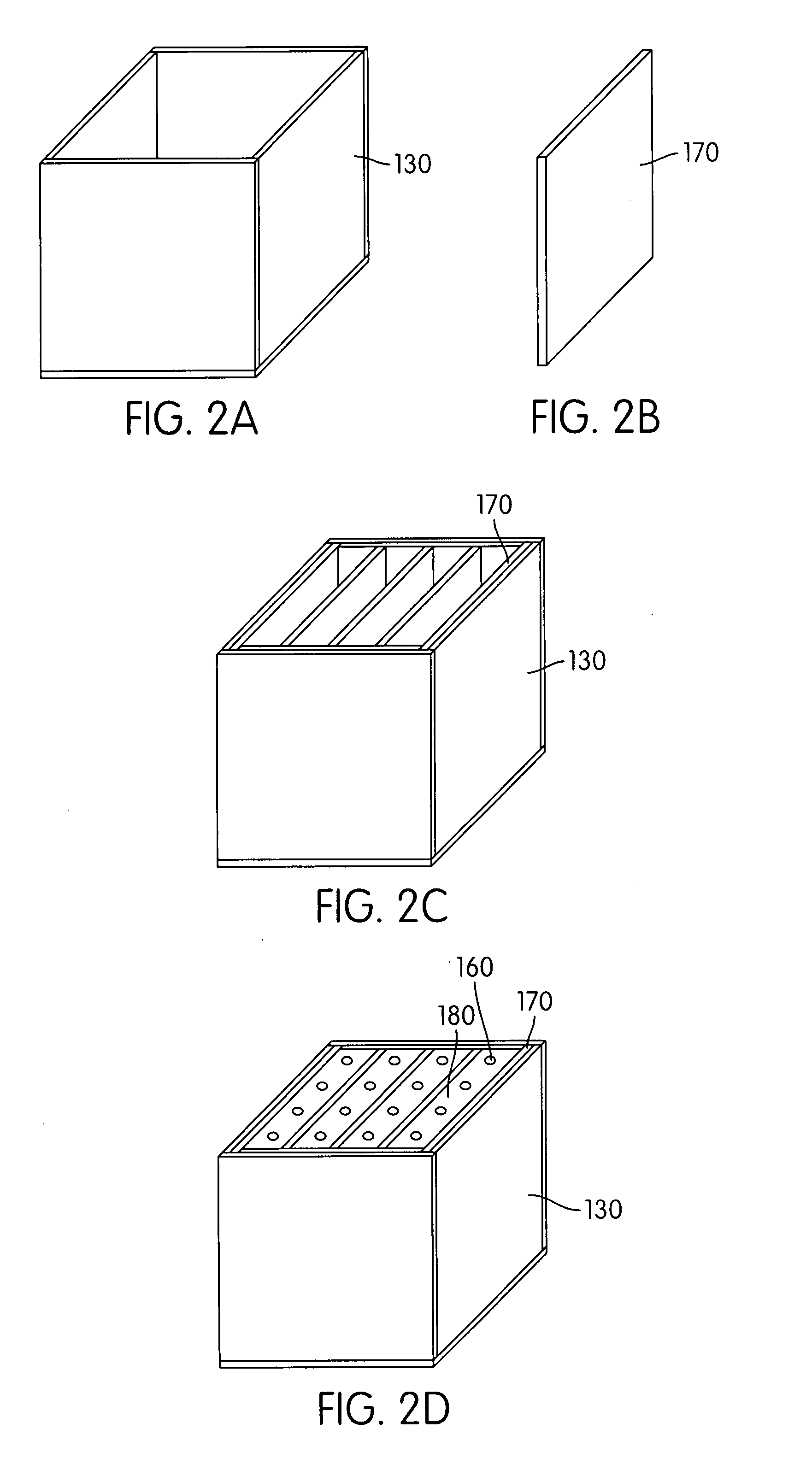

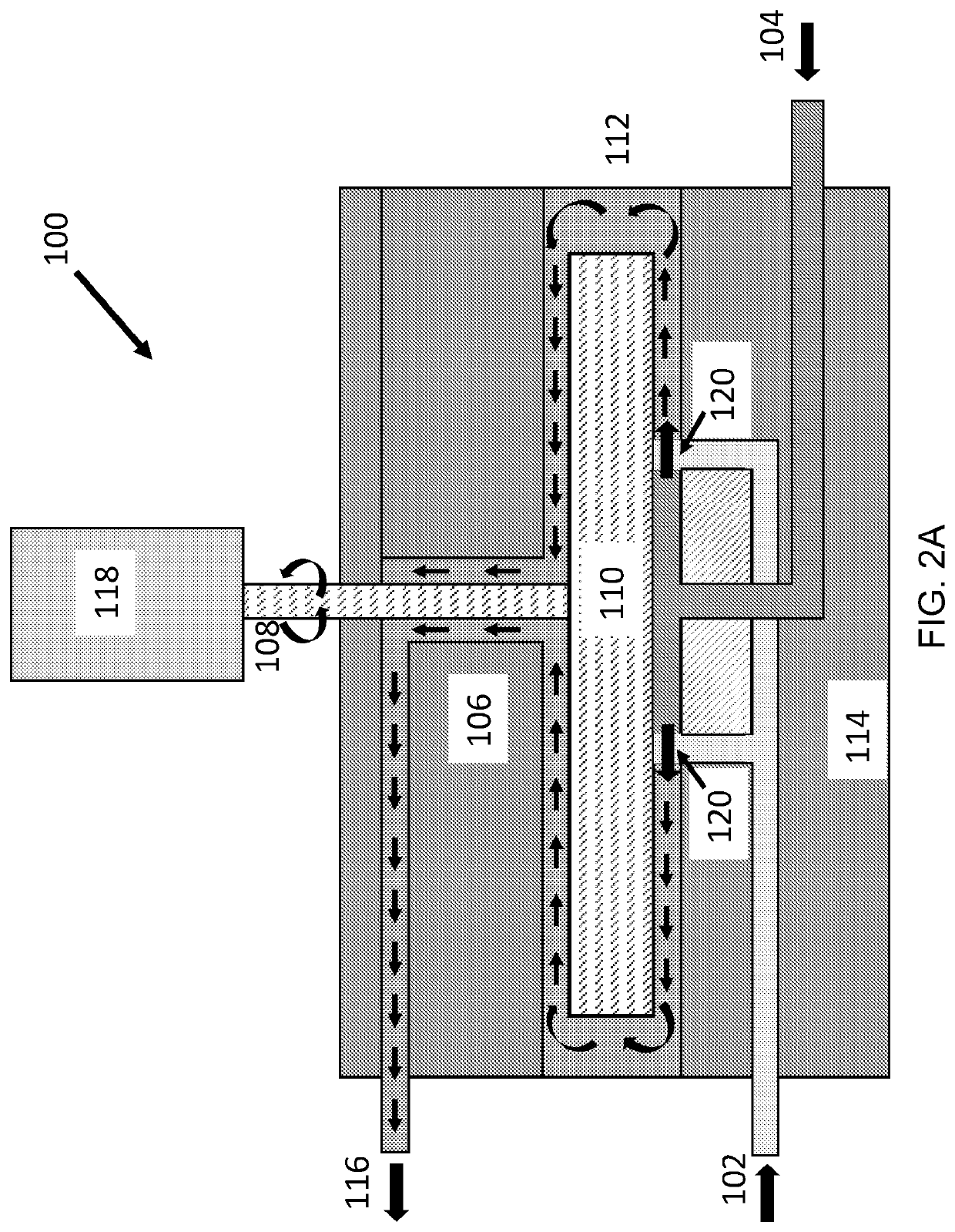

Hydrogen-generating solid fuel cartridge

InactiveUS20070243431A1Lower the diffusion barrierIncrease probabilityReactant parameters controlWater management in fuel cellsHydrogenSolid fuel

Disclosed herein is a novel hydrogen-generating, solid fuel cartridge which may be used to provide hydrogen to a proton exchange membrane (PEM) fuel cell. The cartridge contains a mixture of the hydrogen-generating solid fuel and a catalyst. The solid fuel / catalyst mixture has a packing fraction greater than about 55 percent. Throughout the fuel / catalyst mixture is means for distributing the liquid reactant; there is also a network of hydrogen-collecting, gas permeable membranes for removing the hydrogen product from the cartridge. The hydrogen-generating solid fuel cartridge may further include a liquid reactant distribution plate for distributing the liquid reactant to the solid fuel / catalyst mixture in a substantially uniform manner. The distribution plate has distribution channels arranged in a fractal pattern.

Owner:INTEMATIX

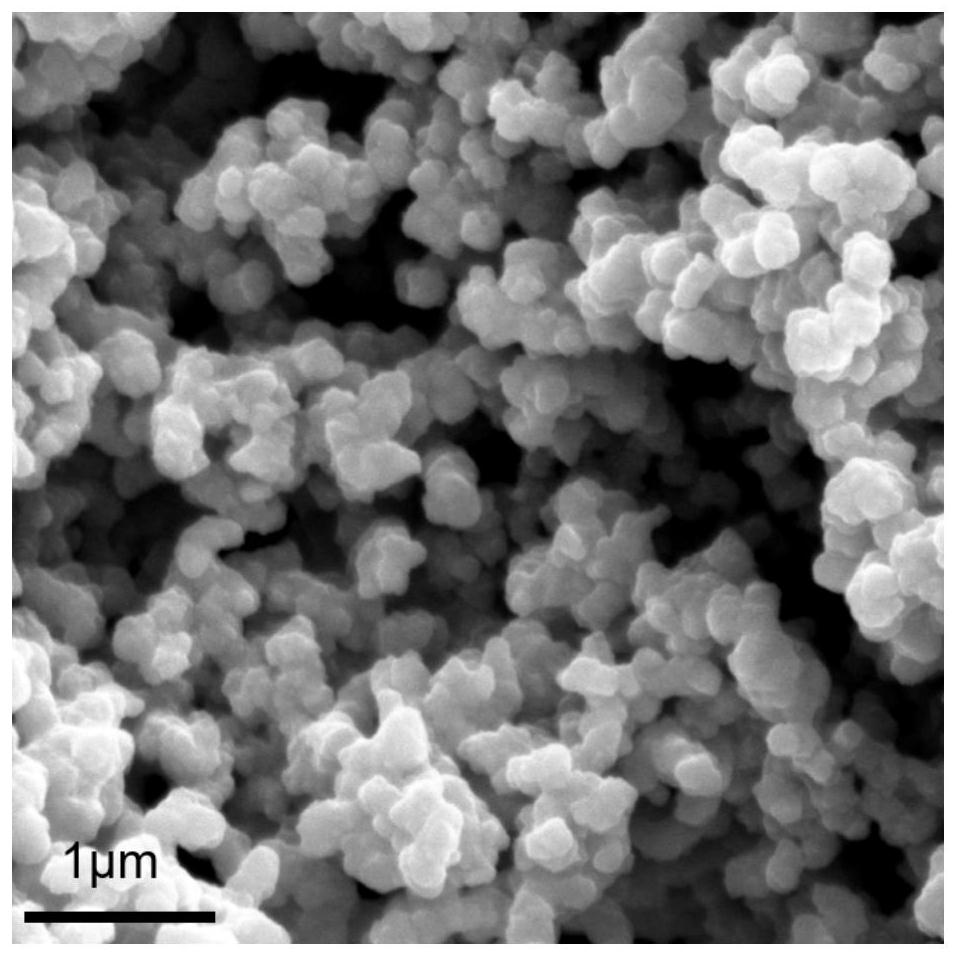

Pressureless sintering preparation method for boron carbide ceramic

The invention relates to a pressureless sintering preparation method for boron carbide ceramic, and coarse particle powder with the particle size larger than 2 micrometers is taken as raw materials. The method comprises the following steps that 70-80 wt % of boron carbide powder (D50>=2 micrometers), 4-8 wt% of carbon powder and 0.7-2 wt% of yttrium oxide powder are put into a ball mill mixing container, ball mill slurrying is performed after binding agents, dispersing agents and deionized water are added, and the solid phase content of obtained slurry is 25-45 wt%; the obtained slurry is prepared into granulating powder with a spray drying granulating machine; the granulating powder is pressed into green bodies by adopting a dry-pressing molding technology or isostatic cool pressing molding technology at 100-200 MPa; the green bodies are placed in a vacuum furnace, a vacuum or normal pressure sintering mode is adopted, heat preservation is performed for 0.5-5 h at the temperature of 2000 DEG C-2300 DEG C, sintering is completed, and then the boron carbide ceramic is obtained. According to the pressureless sintering preparation method for the boron carbide ceramic, due to the fact that the coarse particle boron carbide powder which is low in cost is adopted as the raw materials and the pressureless sintering technology capable of achieving scale production is adopted, the preparation cost of the boron carbide ceramic can be greatly lowered, and therefore the method is suitable for the fields of nuclear power, semiconductor equipment, armor protection and the like.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

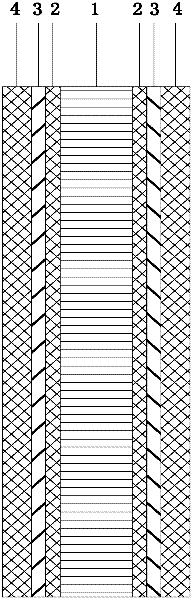

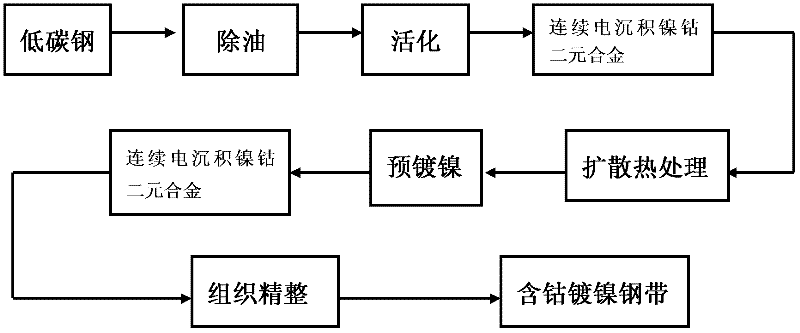

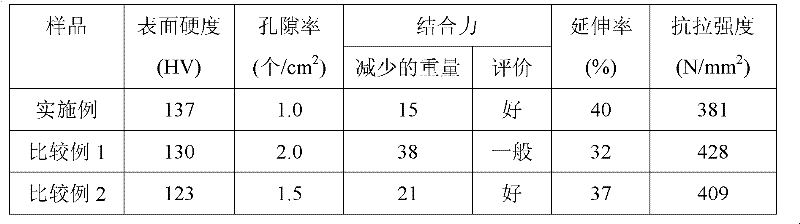

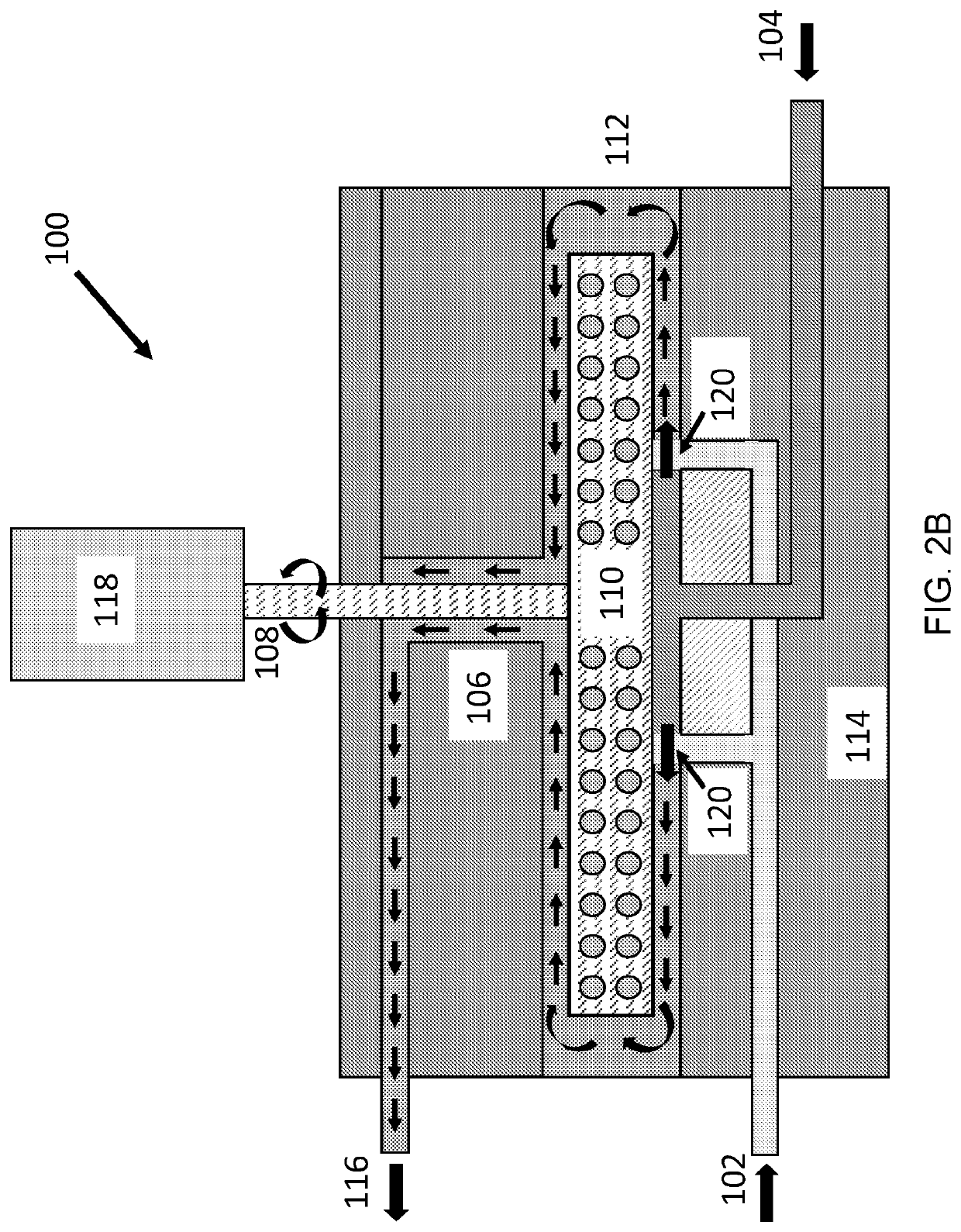

Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

InactiveCN102230200AImprove performanceTimely supplementCell component detailsElectrical batteryNitrogen

The invention discloses a cobalt-containing nickel plated steel strip serving as a lithium battery shell material and a preparation method thereof. The preparation method comprises the following procedures of: (1) pretreating a base material; (2) continuously electrodepositing a nickel-cobalt alloy plating layer on the pre-treated base material; (3) carrying out diffusion annealing treatment on the nickel-cobalt alloy plating layer under a protective atmosphere like high-purity nitrogen; (4) plating a nickel-cobalt alloy plating layer on the metal subjected to the diffusion annealing treatment again; and (5) rolling the plated nickel-cobalt alloy plating layer in a cold manner. The cobalt containing nickel plated steel strip disclosed by the invention is prepared by a special process of tightly combining the nickel-cobalt alloy plating layer and a low-carbon steel strip and then electroplating the nickel-cobalt alloy plating layer and the low-carbon steel strip, shows better corrosion resistance and can be used for shell materials of primary batteries, secondary batteries and lithium ion power cells such as 18650, 26650 and the like.

Owner:XIANGTAN UNIV

Coarse-grained powder based pressureless sintering boron carbide ceramic preparation method

The invention relates to a pressureless sintering boron carbide ceramic preparation method of using more than 2 microns of coarse-grained powder as a raw material. The preparation method comprises the following steps: putting 70-80 wt% of boron carbide (D50 is greater than or equal to 2 microns), 4-8 wt% of powdered carbon, 0.7-2 wt% of yttrium oxide powder and the balance a binder and a dispersant into a mixing container of a ball mill, adding deionized water and ball-milling for pulping so as to obtain slurry with solid content being 25-45 wt%; preparing granulation powder from the slurry by using a spray drying granulating machine; pressing the granulation powder at 100-200 MPa by a dry pressing or isostatic cool pressing process to generate a green body; and putting the green body into a vacuum furnace, and carrying out thermal insulation at 200-2300 DEG C for 0.5-5h to finish sintering by a vacuum or pressureless sintering mode so as to obtain boron carbide ceramic. As the low-cost coarse-grained boron carbide powder is used as the raw material, manufacturing cost of the boron carbide ceramic can be reduced greatly by the pressureless sintering process for large-scale production. The boron carbide ceramic is suitable for fields of nuclear power, semiconductor equipment, armor protection and the like.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

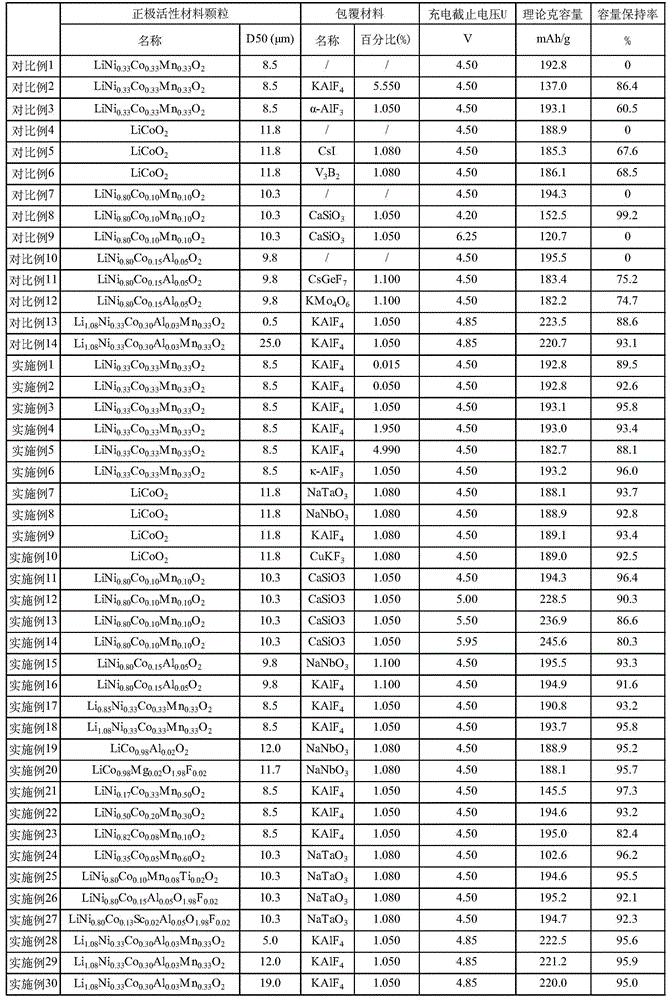

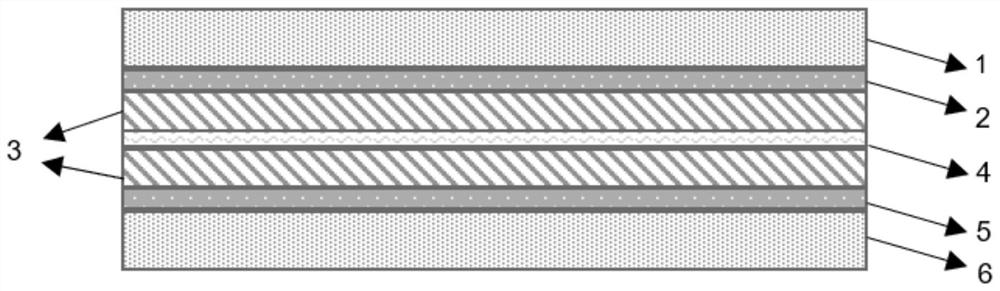

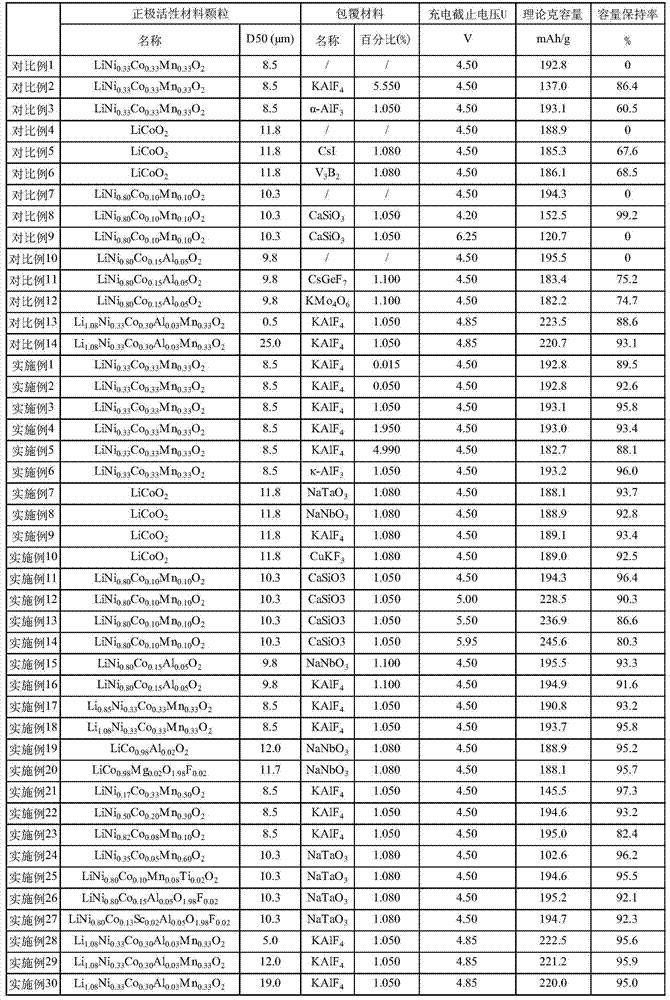

Composite positive electrode active material and lithium ion secondary battery

ActiveCN105226271ALower diffusion barrierDiffusion fastCell electrodesSecondary cellsComposite oxideMaterials science

The invention provides a composite positive electrode active material and a lithium ion secondary battery. The composite positive electrode active material comprises positive electrode active material particles, and a coating material which is positioned on the external of the positive electrode active material particles for coating the positive electrode active material particles. The positive electrode active material particles are layered lithium composite oxide; the general formula of the layered lithium composite oxide is Li1+xNiaCobM (1-a-b)Y2, wherein x is greater than or equal to minus 0.1 and less than or equal to 0.2; a is greater than or equal to 0 and less than or equal to 1, b is greater than or equal to 0.05 and less than or equal to 1, and a+b is greater than or equal to 0.05 and less than or equal to 1; M is selected from one or more of Mg, Zn, Ga, Ba, Al, Fe, Cr, Sn, V, Mn, Sc, Ti, Nb, Mo or Zr; Y is selected from one or more of O, or F; the bulk structure of the coating material is P4 / mbm space group; and the lithium ion secondary battery comprises the composite positive electrode active material. The lithium ion secondary battery is higher in energy density and better in cycle performance under high voltage.

Owner:CONTEMPORARY AMPEREX TECH CO

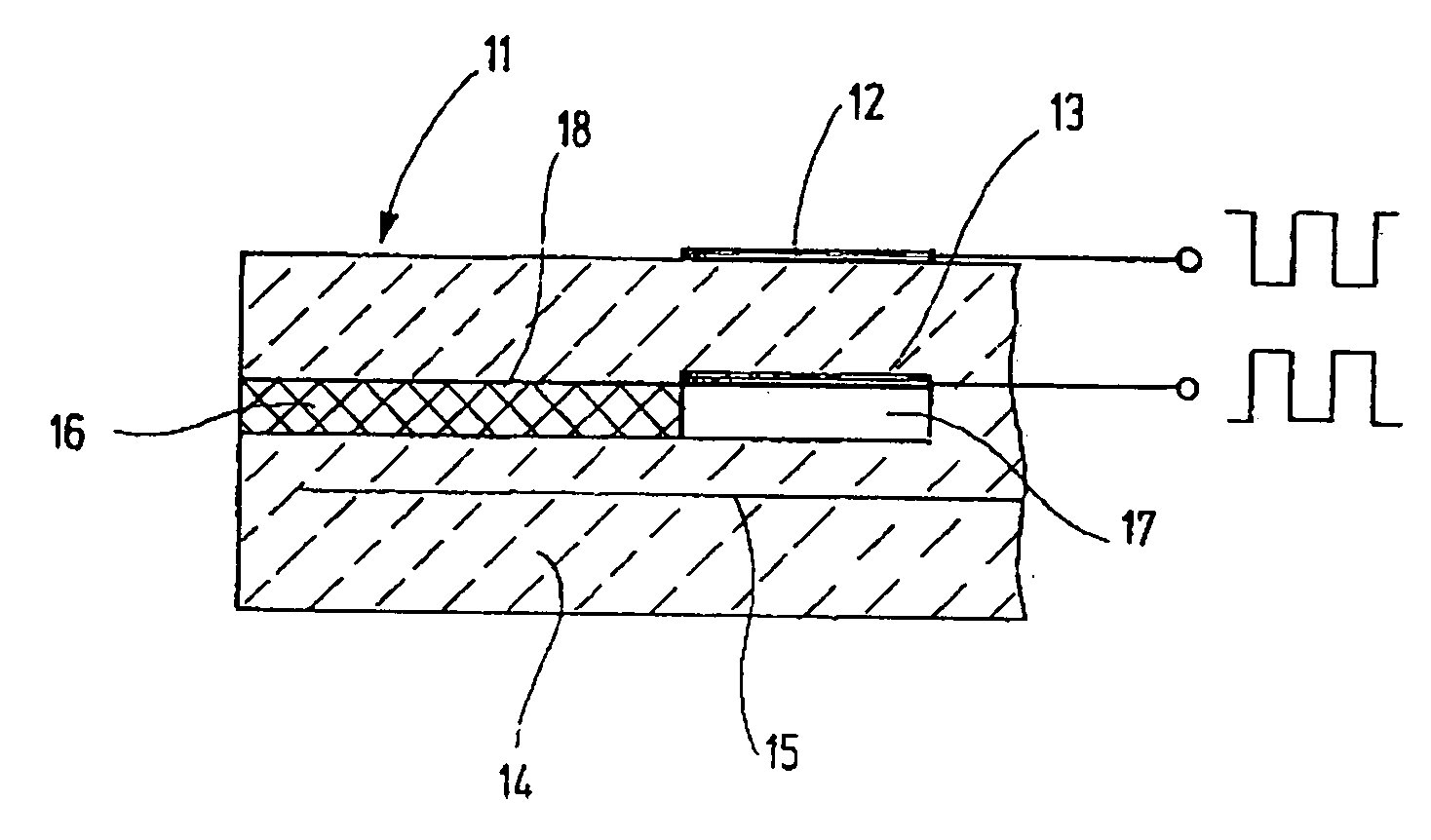

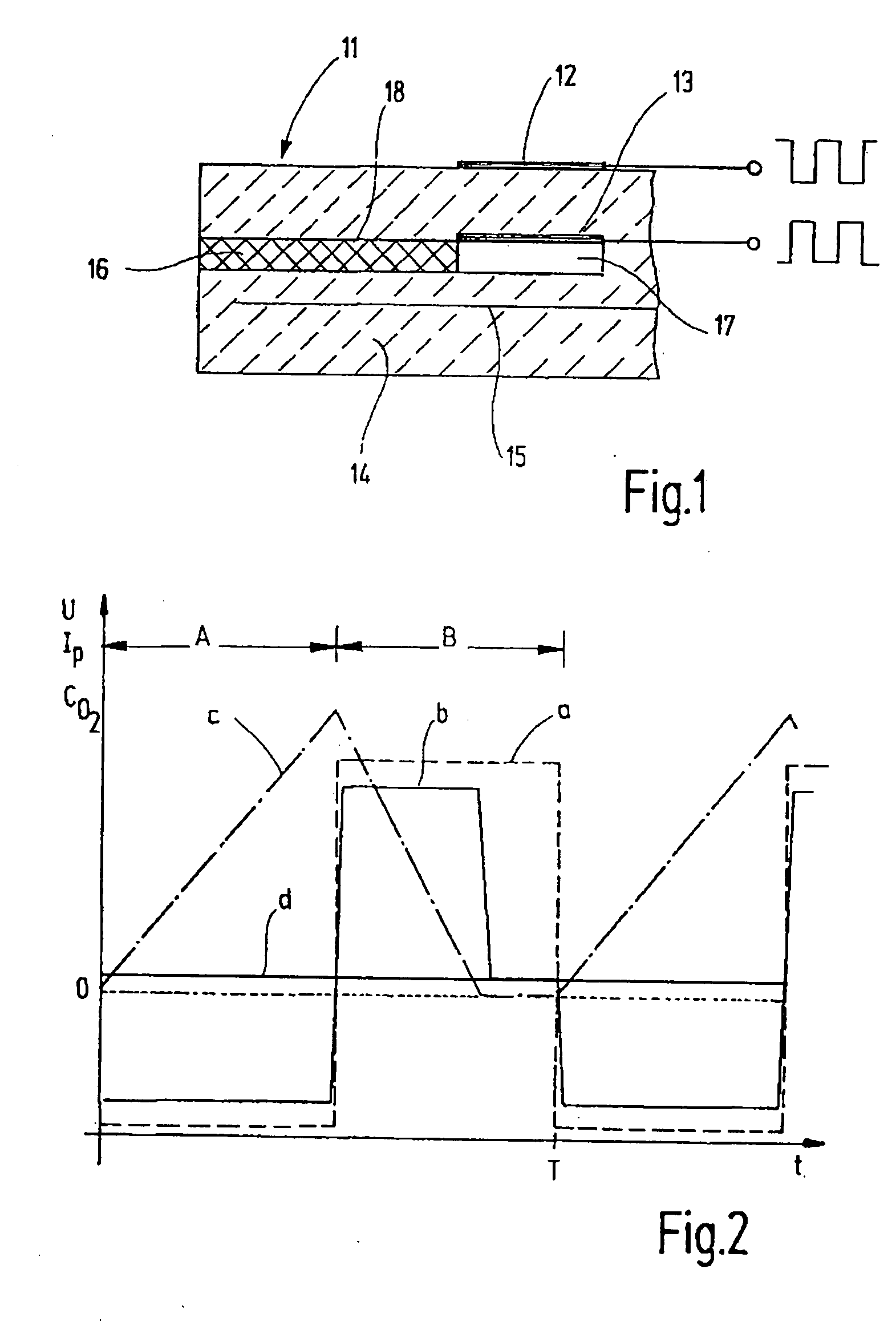

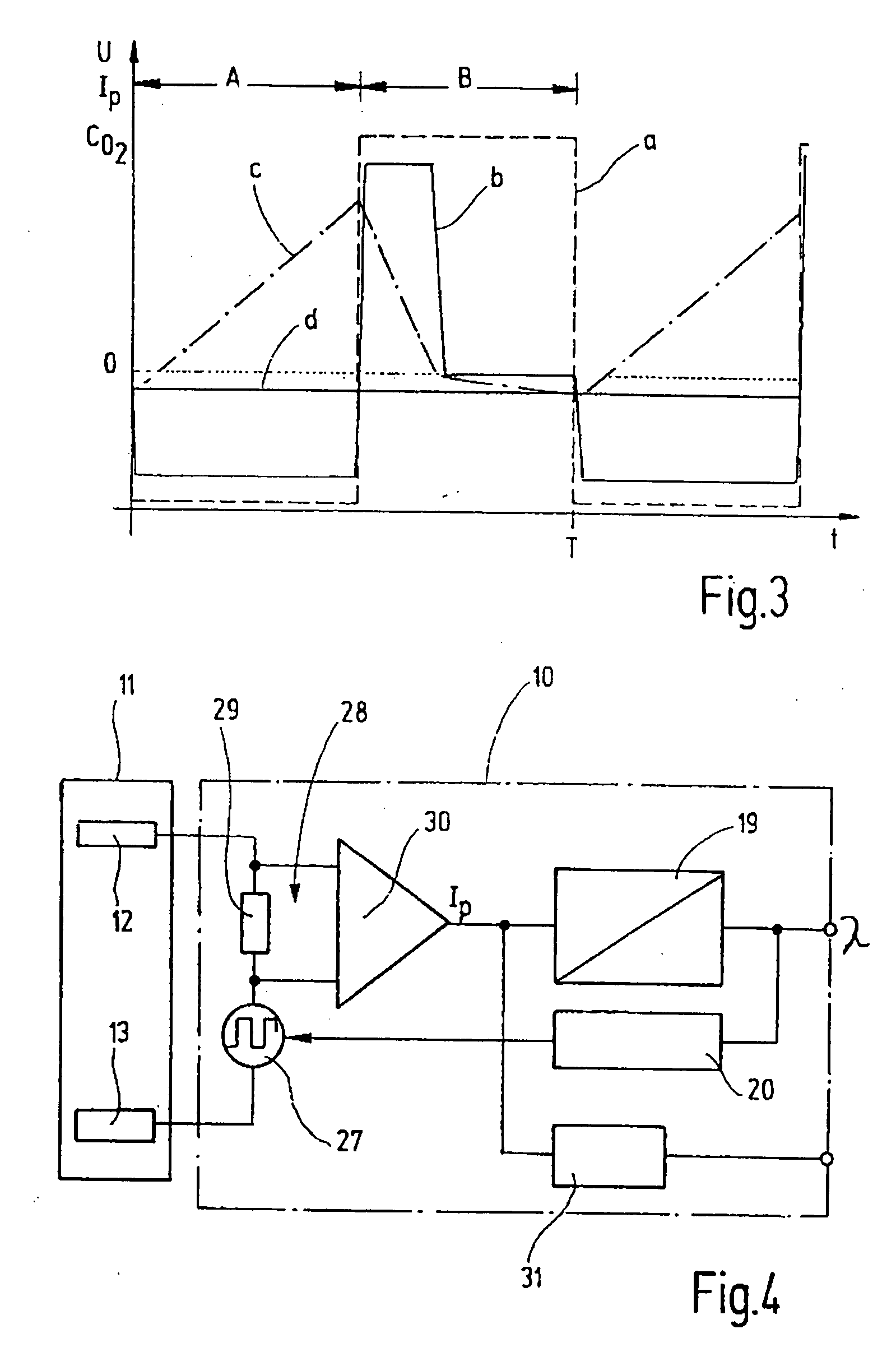

Gas Sensor

InactiveUS20080217174A1High measurement accuracyLower the diffusion barrierMaterial electrochemical variablesSolid state electrolyteCombustion

A gas sensor is provided for determining the concentration of a gas component in a measuring gas, in particular for determining the oxygen concentration in the exhaust gas of internal combustion engines, which has an electrode pair situated on a solid-state electrolyte and made up of an outer pump electrode and an inner pump electrode, which is accessible to the measuring gas supplied via a diffusion barrier, the electrode pairs being triggered in a clocked manner and having a potential of varying polarity applied in each clock-pulse period. To improve the measuring precision of the gas sensor without additional electrodes, a cavity is situated between the diffusion barrier and the inner pump electrode, the cavity serving as storage volume for the oxygen pumped through the solid-state electrolyte.

Owner:ROBERT BOSCH GMBH

Preparation method of zirconium oxide-mullite high-porosity ceramic material

ActiveCN107903080AAvoid introducingImprove high temperature resistanceCeramicwareZirconium hydrideMullite

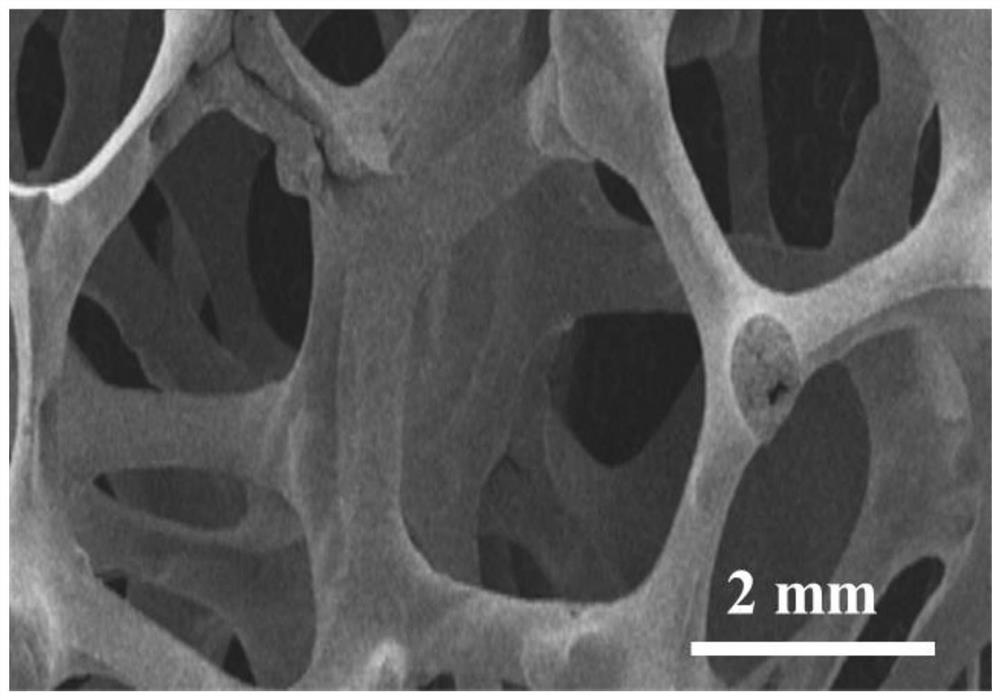

The invention discloses a preparation method of a zirconium oxide-mullite porous ceramic material. The preparation method is characterized in that aluminum oxide and zircon sand are taken as main rawmaterials, yttrium oxide is taken as a stabilizer, aluminum fluoride is taken as an additive, a forming mode combining polyurethane foam dipping and gel solidification is adopted, and the zirconium oxide-mullite porous ceramic material with a needle-shaped mullite whisker structure is prepared through an in-situ synthesis technology; and a solvent in a blank is volatilized and organic substances are split at a high temperature to form a porous structure which has the characteristics of being high in porosity (greater than 80%), uniform in aperture distribution, excellent in high-temperature mechanical property and excellent in thermal impact resistance.

Owner:武汉钢铁有限公司

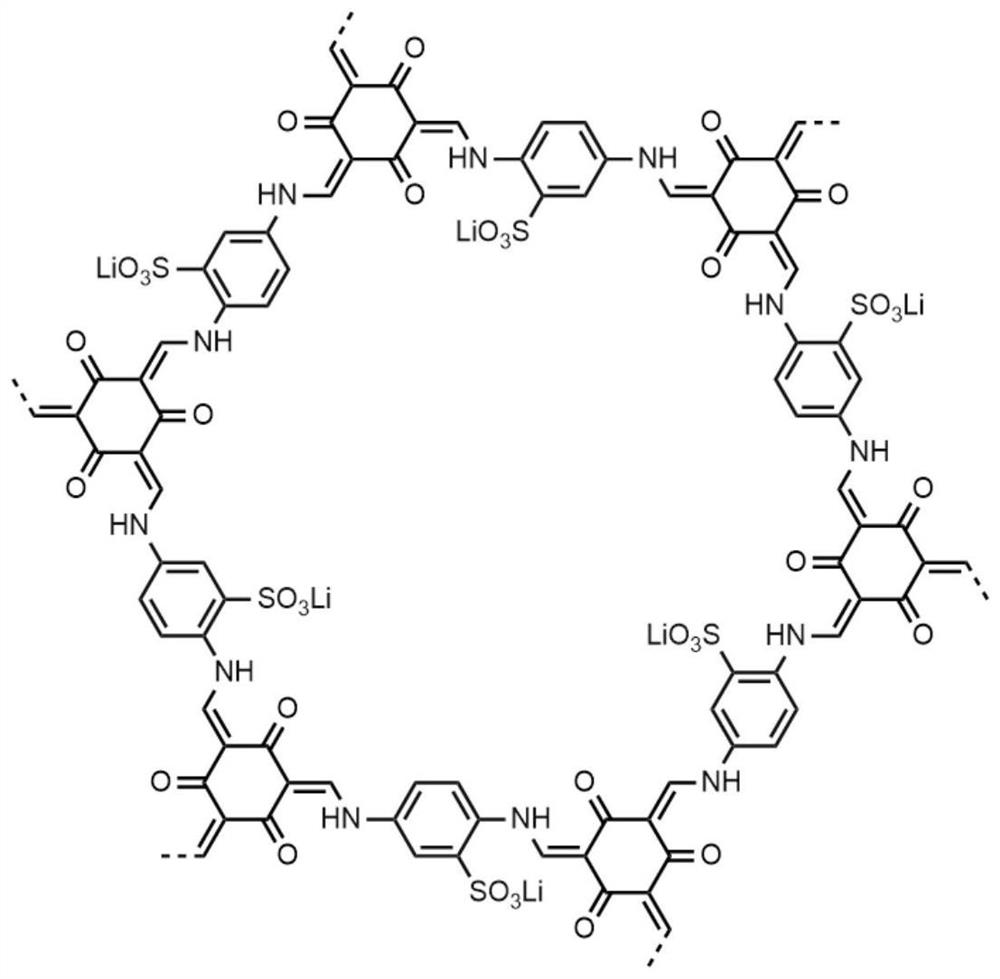

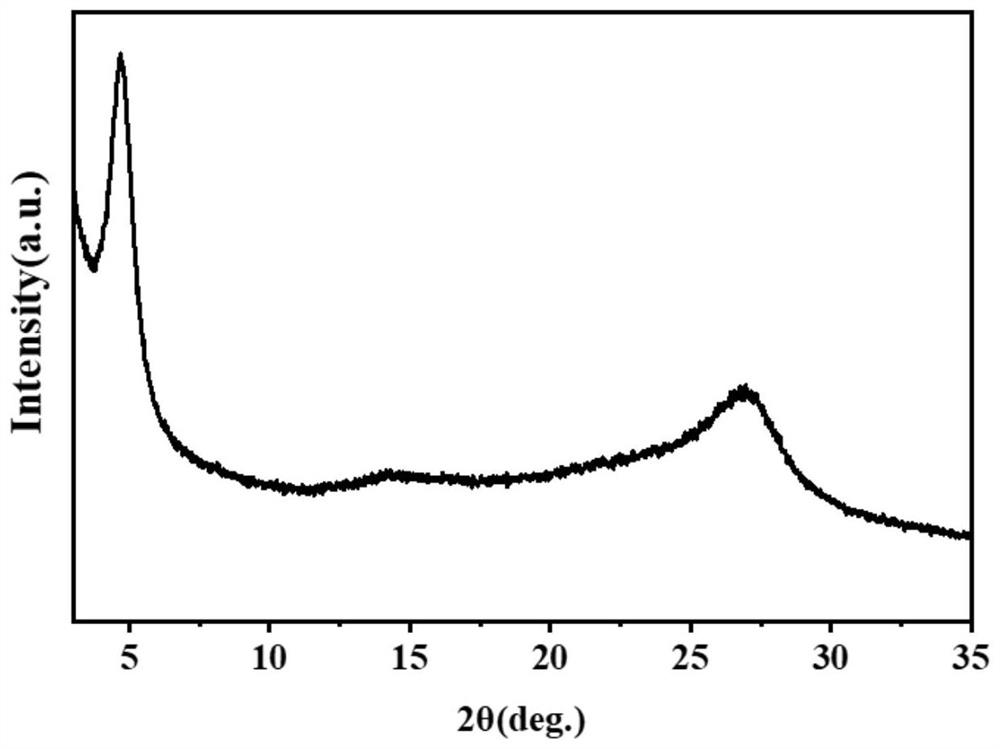

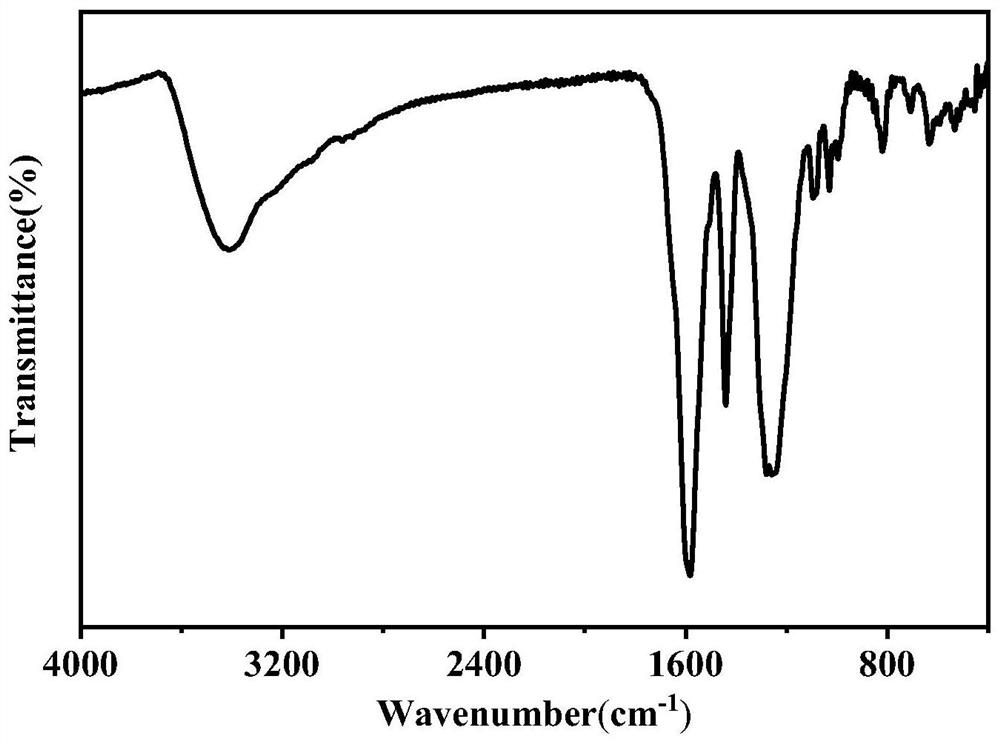

Lithiation covalent organic framework composite polymer electrolyte as well as preparation and application thereof

PendingCN112786960AEnhanced interactionLower the barrierSolid electrolytesSecondary cellsCovalent organic frameworkComposite polymer

The invention discloses a lithiation covalent organic framework composite polymer electrolyte as well as a preparation method and application thereof. The lithiation covalent organic framework composite polymer electrolyte comprises a lithiated covalent organic framework, a polymer and lithium salt. The lithium ion diffusion barrier is reduced through the interaction between the lithiated covalent organic framework and the polymer, and a rapid channel is provided between polymer chain segments, so that the lithium ion conductivity is improved. The invention further provides a solid-state lithium ion battery comprising the lithiation covalent organic framework composite polymer electrolyte. The lithiation covalent organic framework composite polymer electrolyte provided by the invention can improve electrochemical performances such as cycling stability, specific capacity, safety and the like of a battery, and the lithiation process is simple and convenient and the lithiation covalent organic framework composite polymer electrolyte has universality.

Owner:TIANJIN UNIV

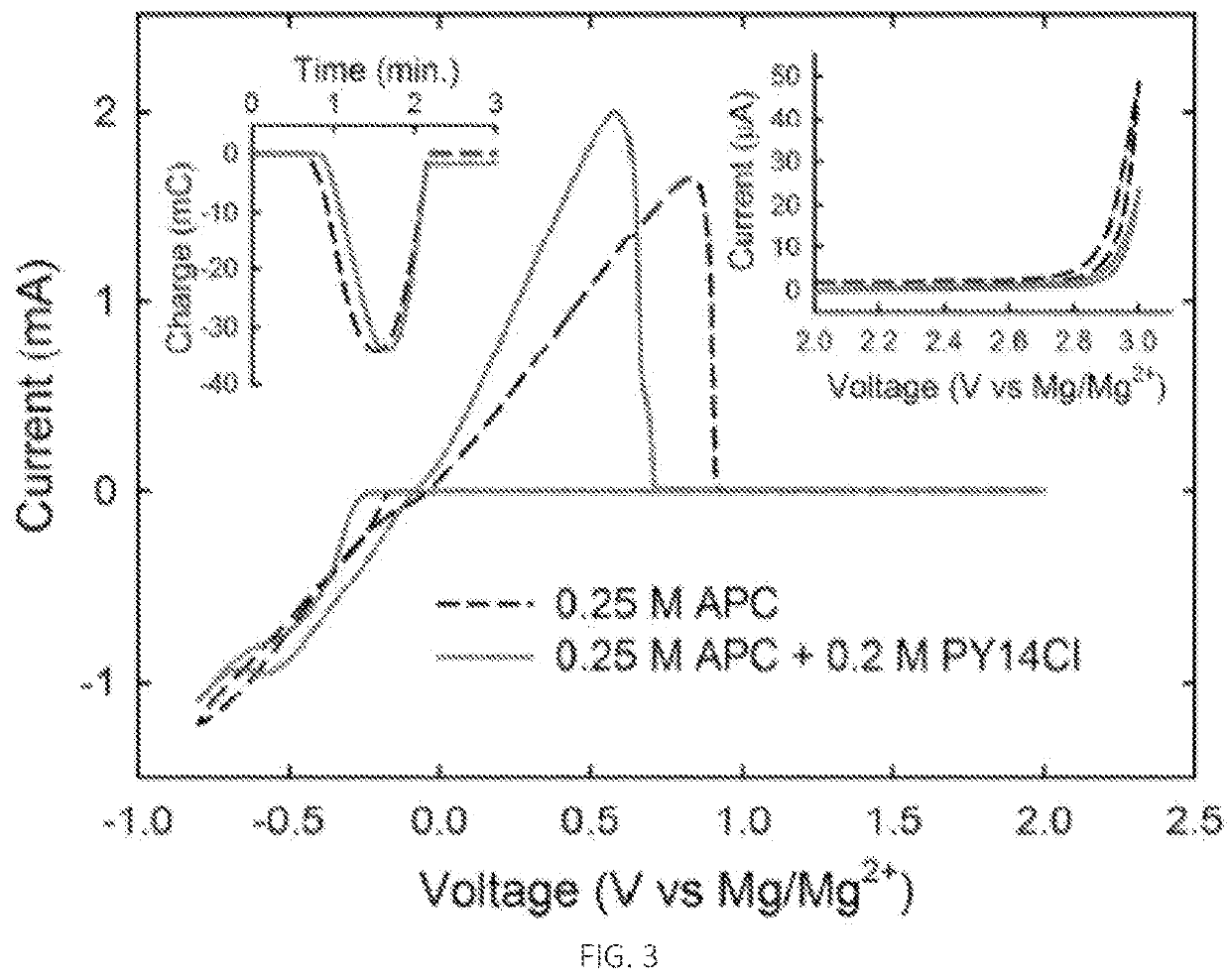

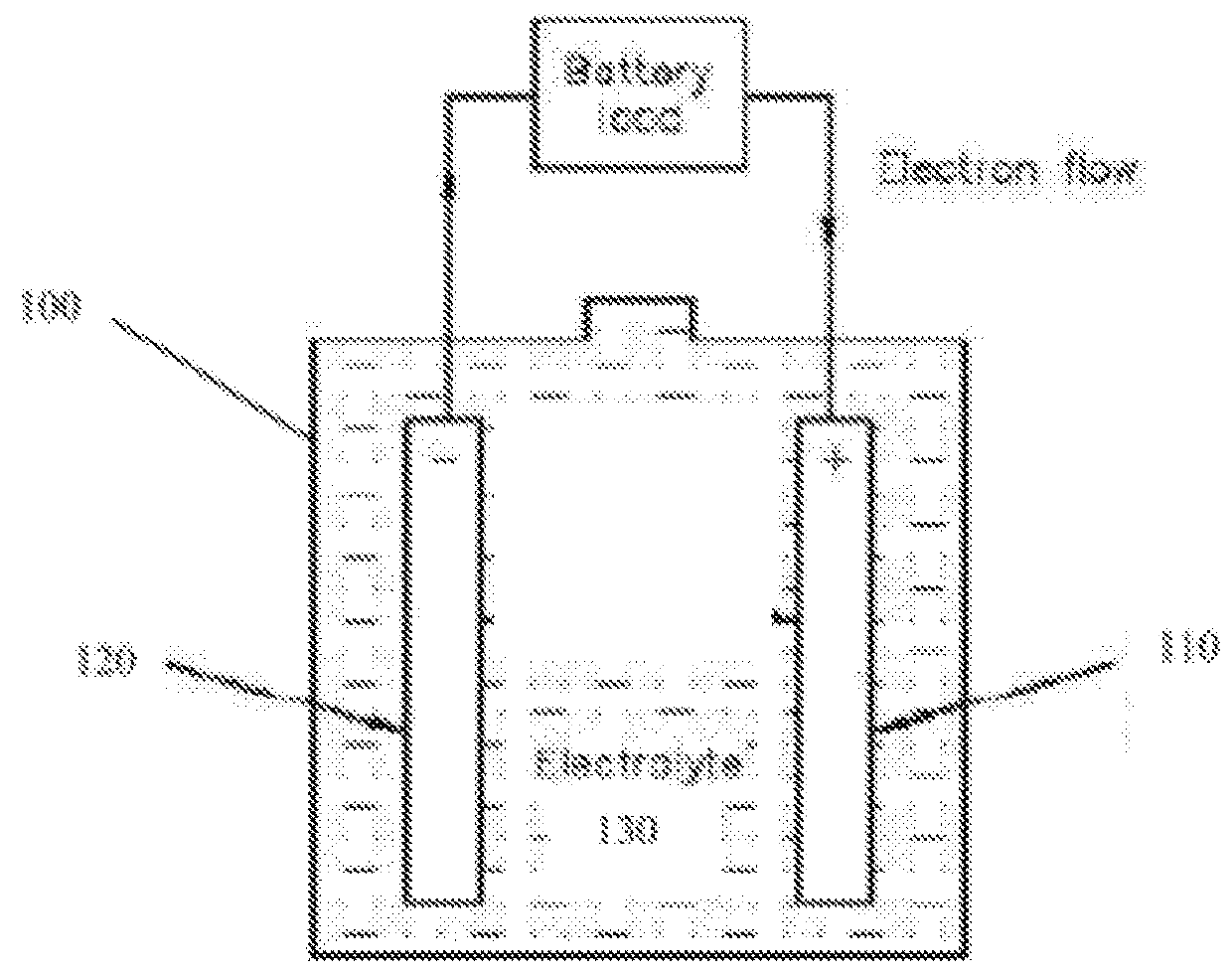

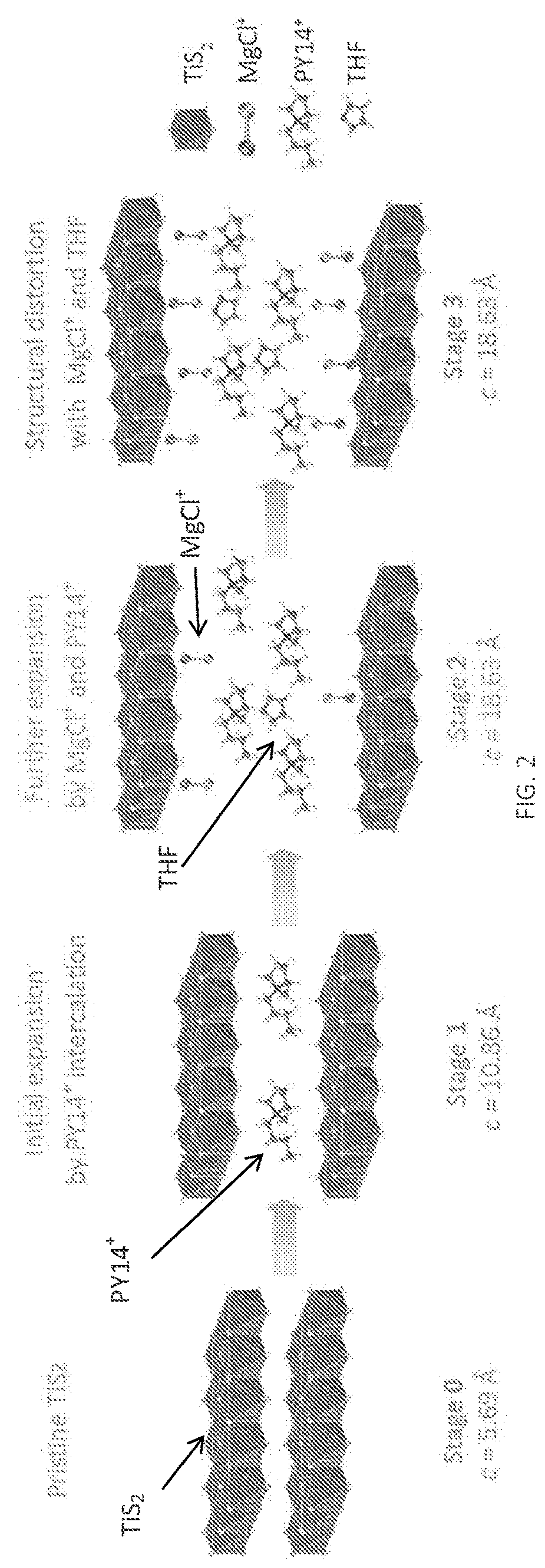

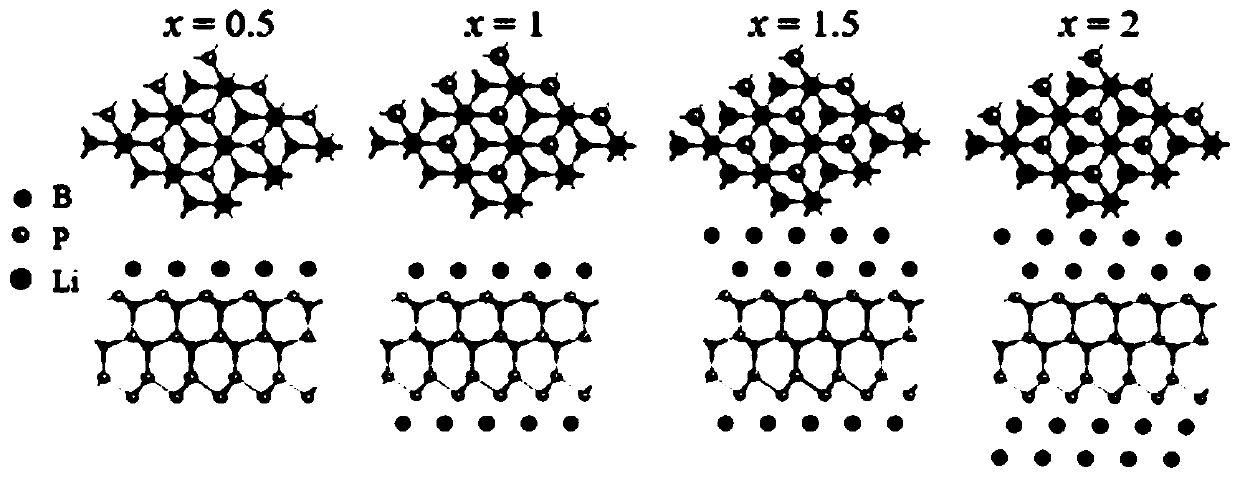

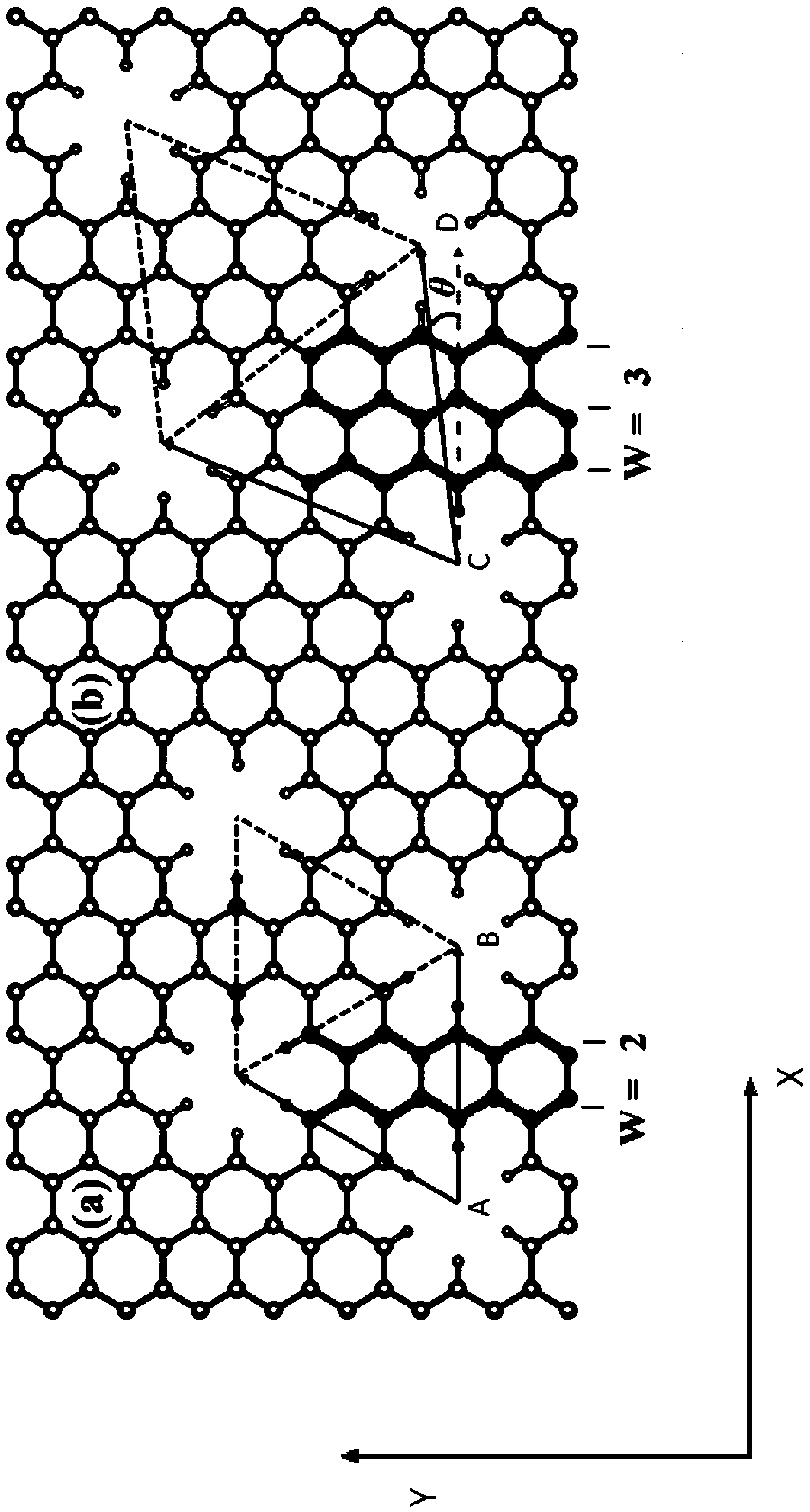

Method of activating two-dimensional materials for multivalent/polyatomic-ion intercalation battery electrodes

InactiveUS20180183038A1Increase capacityExcellent rate performanceElectrode manufacturing processesSecondary cellsSolvent moleculePolyatomic ion

A method for activating two-dimensional host materials for a multivalent / polyatomic ion battery may include adding a pillaring salt in electrolyte. This process may be followed by in-situ electrochemically intercalating the pillaring ions, solvent molecules and multivalent ions into the van der Waals gap of host materials. After the activation process, the host material is transformed into an interlayer-expanded 2D material with significantly enhanced specific capacity and rate performance for multivalent ion intercalation.

Owner:UNIV HOUSTON SYST

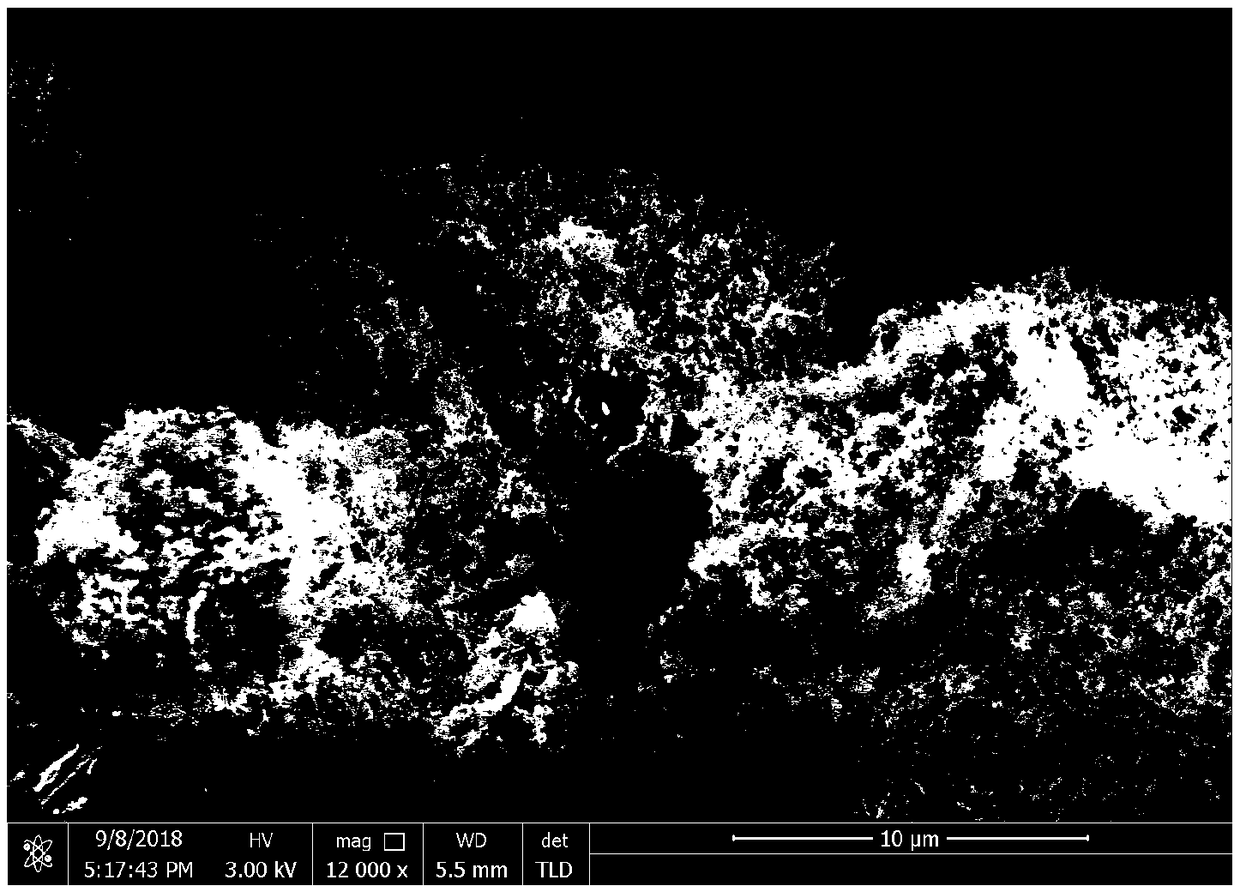

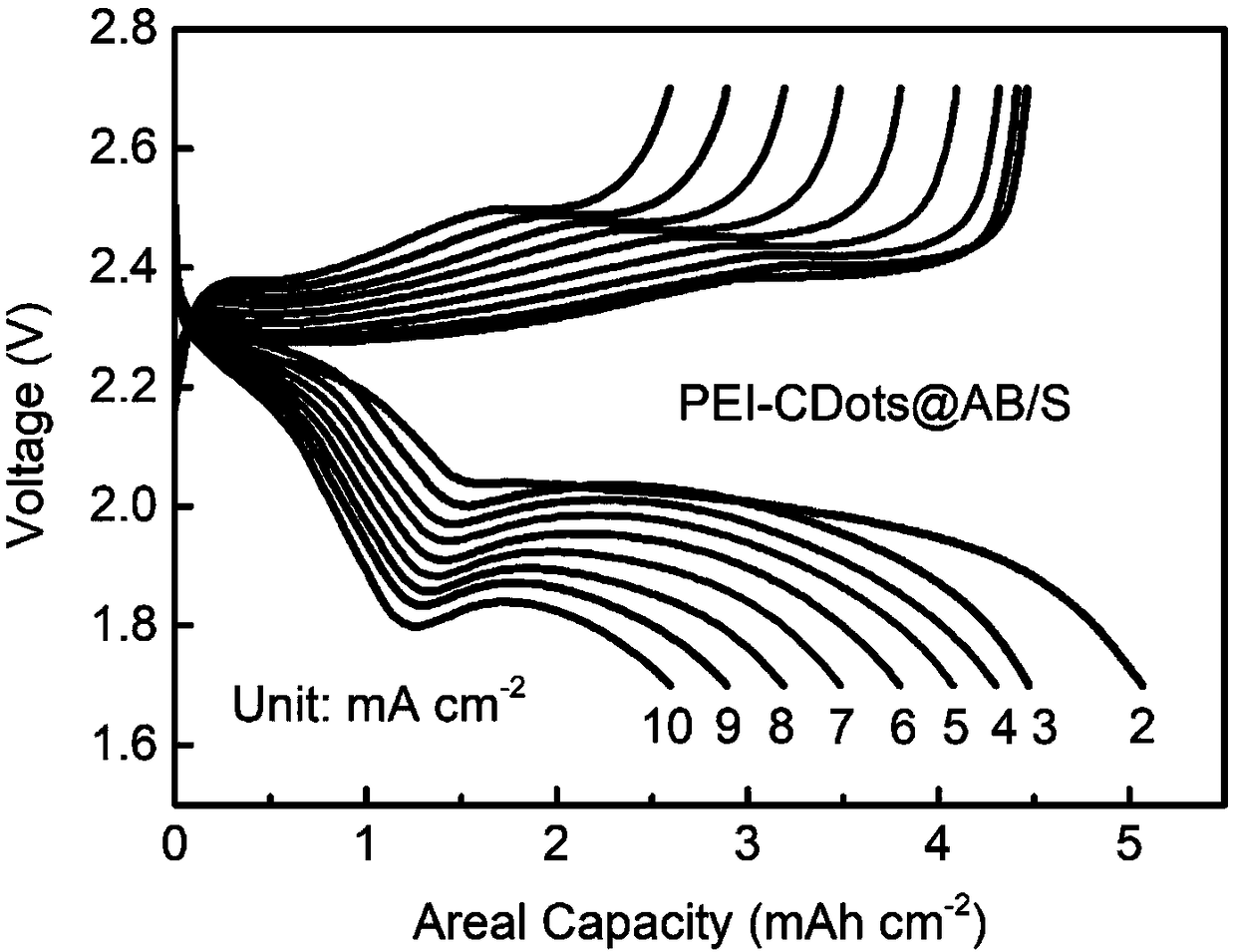

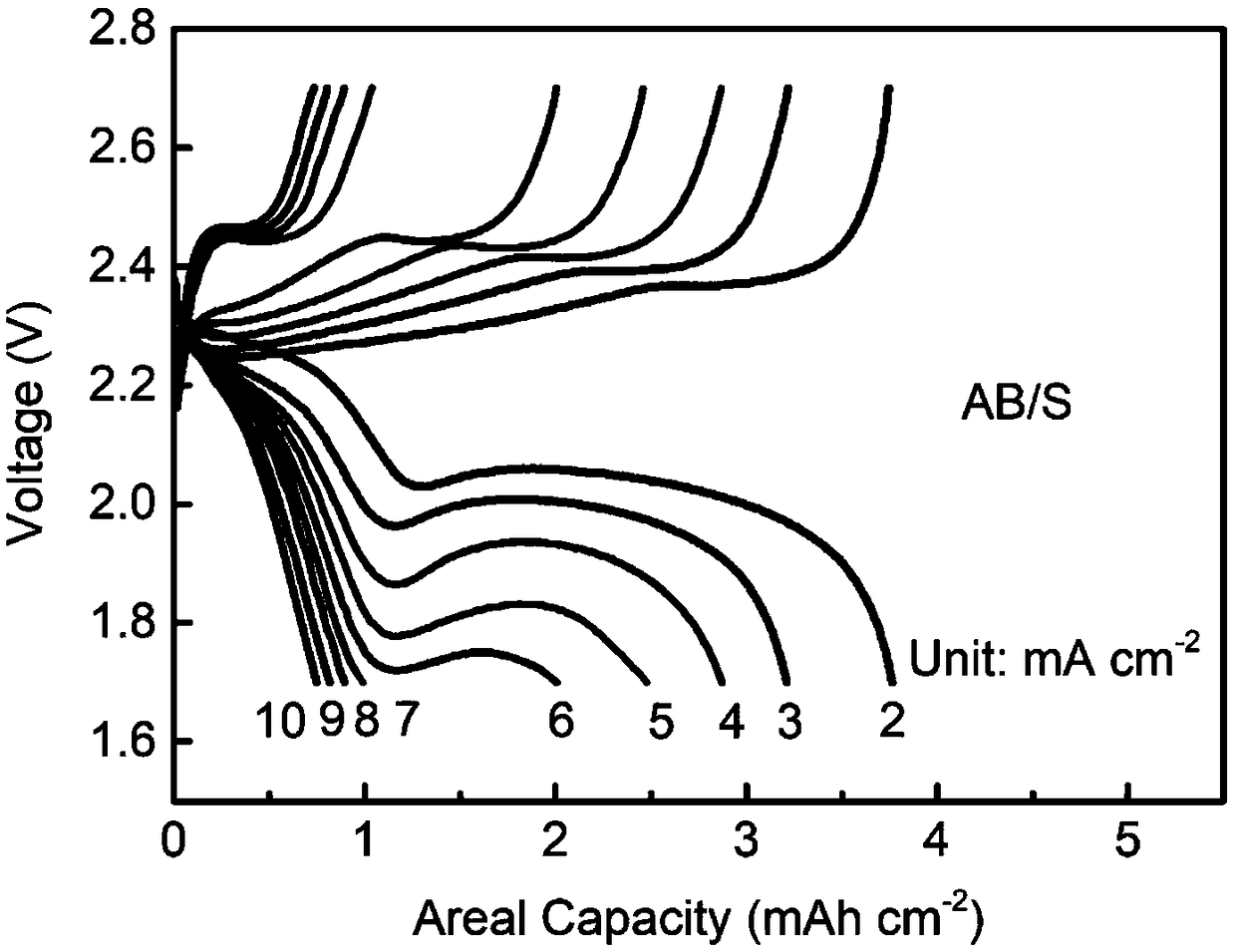

Method for preparing carbon quantum dot modified lithium-sulfur battery positive electrode materials

ActiveCN109494346AIncrease capacityHigh magnificationElectrode carriers/collectorsElectrode collector coatingHigh current densityBattery charge

The invention provides a method for preparing carbon quantum dot modified lithium-sulfur battery positive electrode materials, and belongs to the field of preparation of lithium-sulfur battery positive electrode materials. The method has the advantages that carbon quantum dots with functionalized polyethyleneimine surfaces are used for preparing lithium-sulfur battery positive electrodes, shuttling effects in battery charge and discharge procedures can be inhibited under polysulfide adsorption effects of polyethyleneimine, and accordingly the long cycle performance of lithium-sulfur batteriescan be guaranteed; the method for preparing the carbon quantum dot modified lithium-sulfur battery positive electrode materials includes simple and convenient processes, the capacity, the rates and the cycle performance of the lithium-sulfur batteries under working conditions of high load and high current density can be obviously improved, and accordingly the method has a potential application value in the field of lithium-sulfur batteries.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

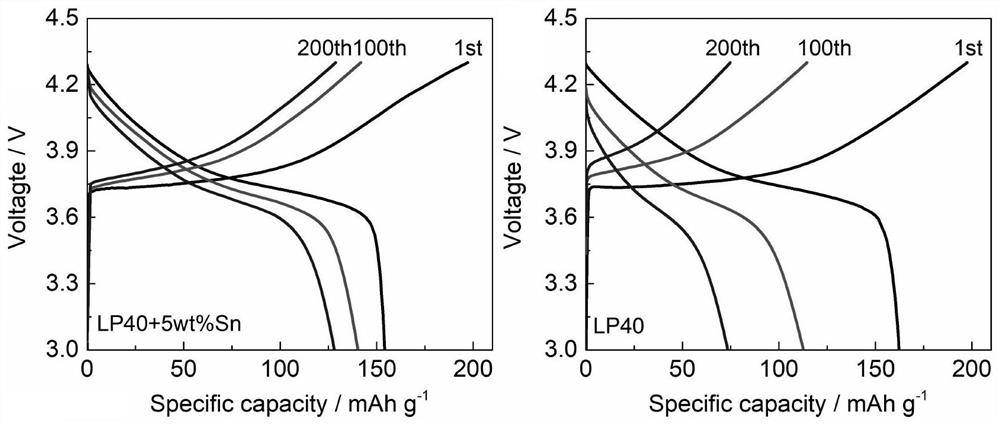

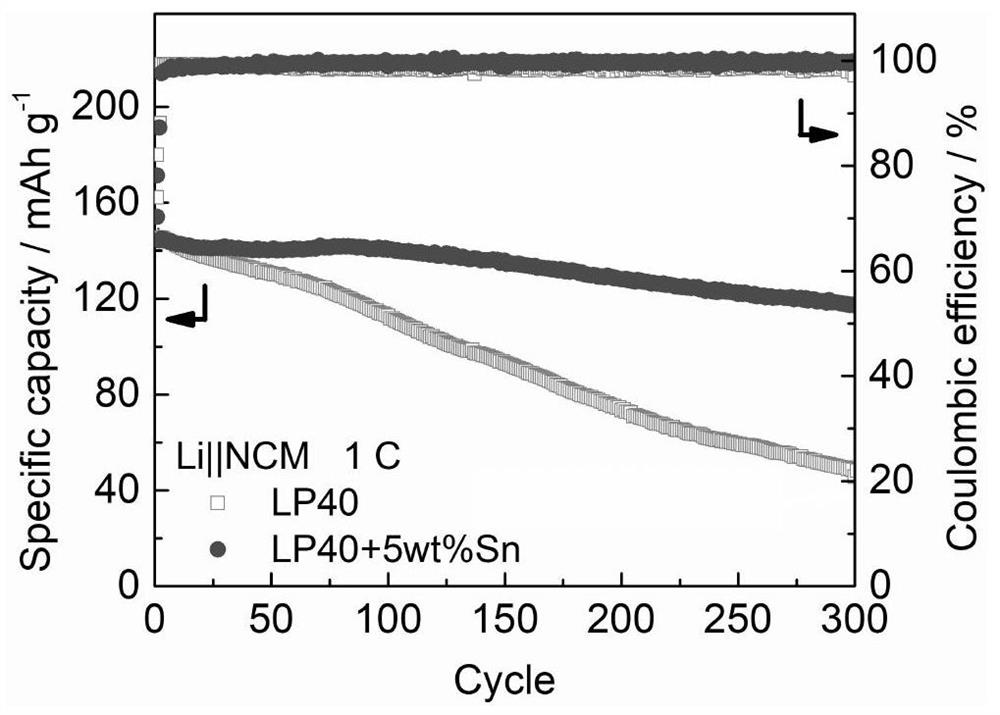

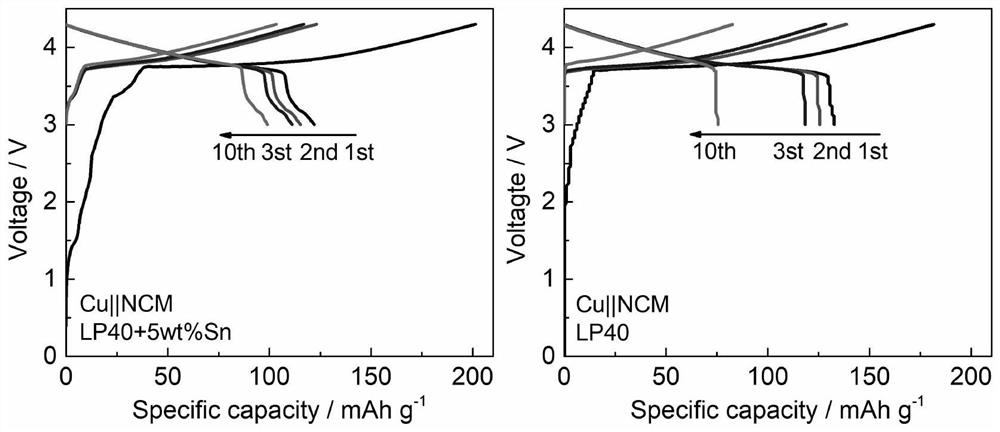

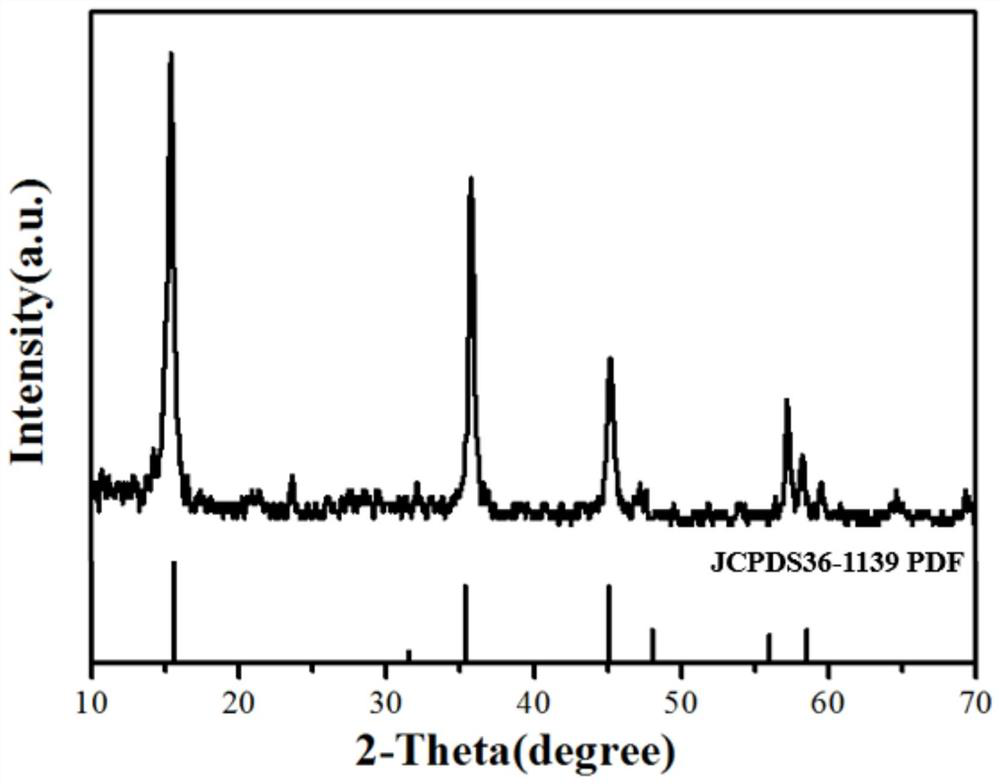

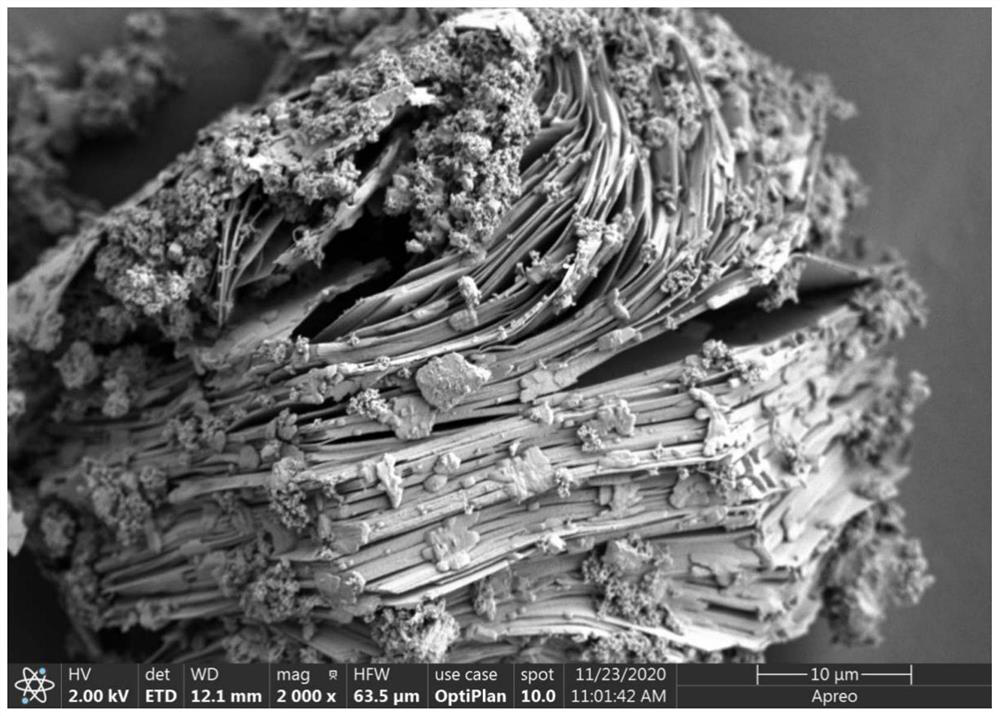

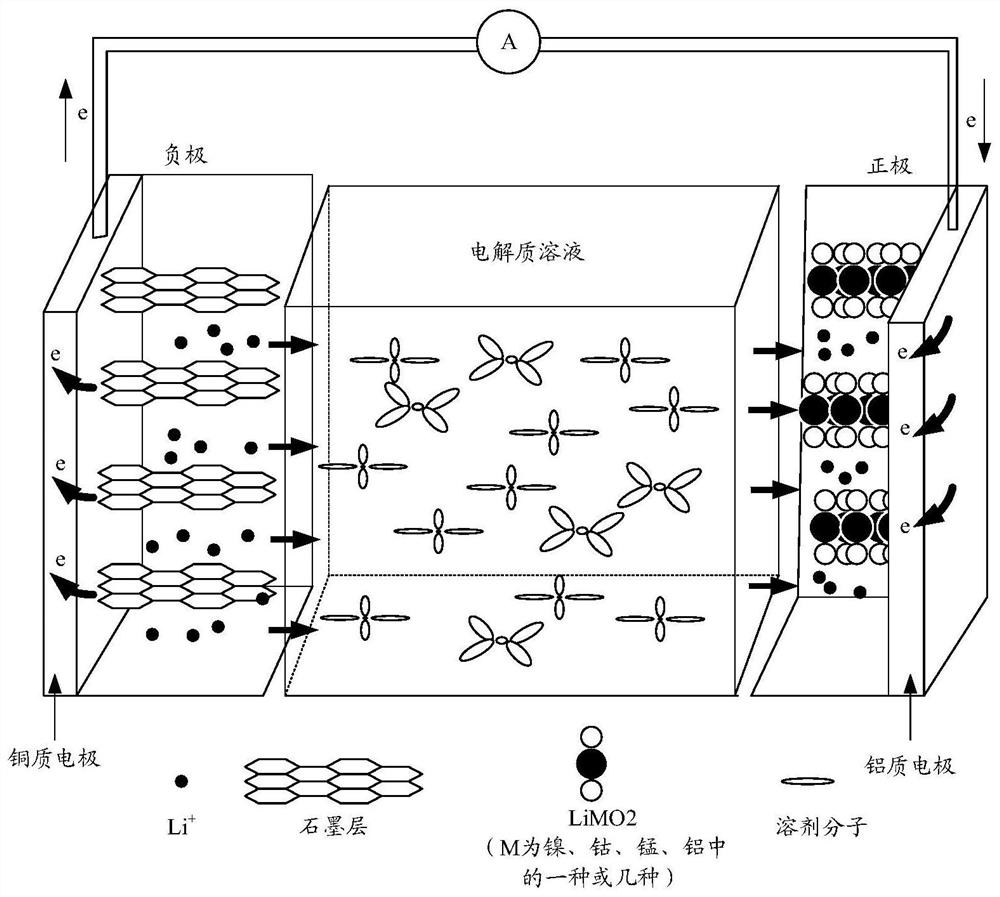

Electrolyte for metal battery and metal battery

PendingCN112670574AElectrochemically activeImprove stabilityFinal product manufactureLi-accumulatorsElectrode potentialElectrolytic agent

The invention provides an electrolyte for a metal battery and the metal battery, and belongs to the technical field of batteries. The electrolyte for the metal battery, provided by the invention, comprises a liquid electrolyte and an electrolyte additive added into the liquid electrolyte, wherein the electrolyte additive is any one or more of indium salt, tin salt, bismuth salt and germanium salt. Because metals such as indium, tin, bismuth and the like have higher electrode potential than lithium, the metal ions can be reduced on the surface of the negative electrode by the lithium, so that an SEI film containing metal components is formed on the surface of the lithium negative electrode in situ. In the circulation process, metal ions in the electrolyte have electrochemical activity, stability of a metal protective layer on the surface of the lithium negative electrode is promoted, the metal can store lithium in an alloy forming mode, and meanwhile, the formed alloy can reduce diffusion barriers during lithium deposition, promote rapid migration of the lithium ions and inhibit growth of lithium dendrites; therefore, the cycling stability of the lithium metal negative electrode is further improved.

Owner:TONGJI UNIV

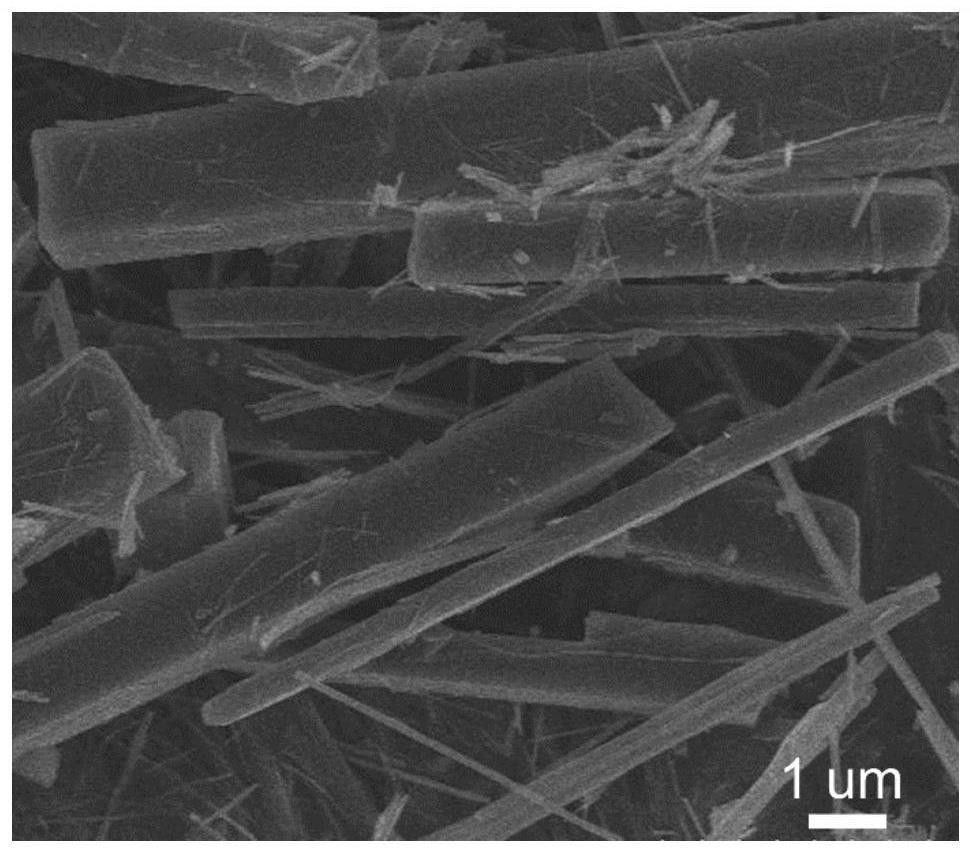

Cobalt-doped vanadium disulfide micron sheet and preparation method thereof

InactiveCN113193198AThe preparation process is simple and easy to obtainUniform structureMaterial nanotechnologyNegative electrodesVanadium disulfideFreeze-drying

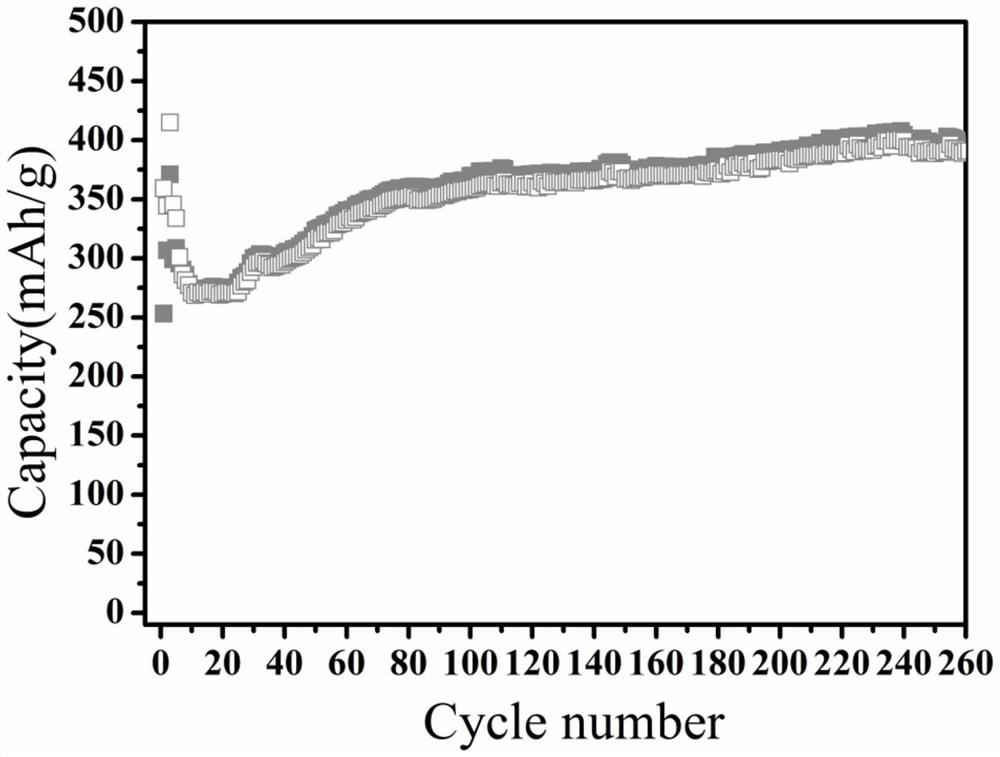

The invention discloses a cobalt-doped vanadium disulfide micron sheet and a preparation method thereof. The preparation method comprises the following steps: 1) mixing a cobalt nitrate methanol solution with the concentration of 0.04-0.08 mol / L and a di-methylimidazole methanol solution with the concentration of 0.16-0.32 mol / L according to the molar ratio of cobalt nitrate to di-methylimidazole being 1:(4-6), stirring, centrifuging, washing and drying to obtain ZIF-67; (2) adding the ZIF-67 obtained in the step (1) into water, adjusting the pH value to be alkaline, uniformly stirring, adding a vanadium source and a sulfur source, and stirring to obtain a mixed solution; wherein the mass ratio of the added vanadium source to the ZIF-67 is (2-7):1, the concentration of the vanadium source in the obtained mixed solution is 0.039 mol / L to 0.12 mol / L, the concentration of the sulfur source is 0.32 mol / L to 0.78 mol / L; (3) heating the mixed solution obtained in the step (2) to 160-180 DEG C, keeping the temperature for 24 hours, naturally cooling, and carrying out suction filtration, washing and freeze drying to obtain the cobalt-doped vanadium disulfide micron sheet. The preparation method is simple in process and easy to obtain, and the prepared cobalt-doped vanadium disulfide micron sheet has the capacity of 390 mAh / g under the current density of 0.5 A / g as a sodium-ion battery negative electrode material.

Owner:SHAANXI UNIV OF SCI & TECH

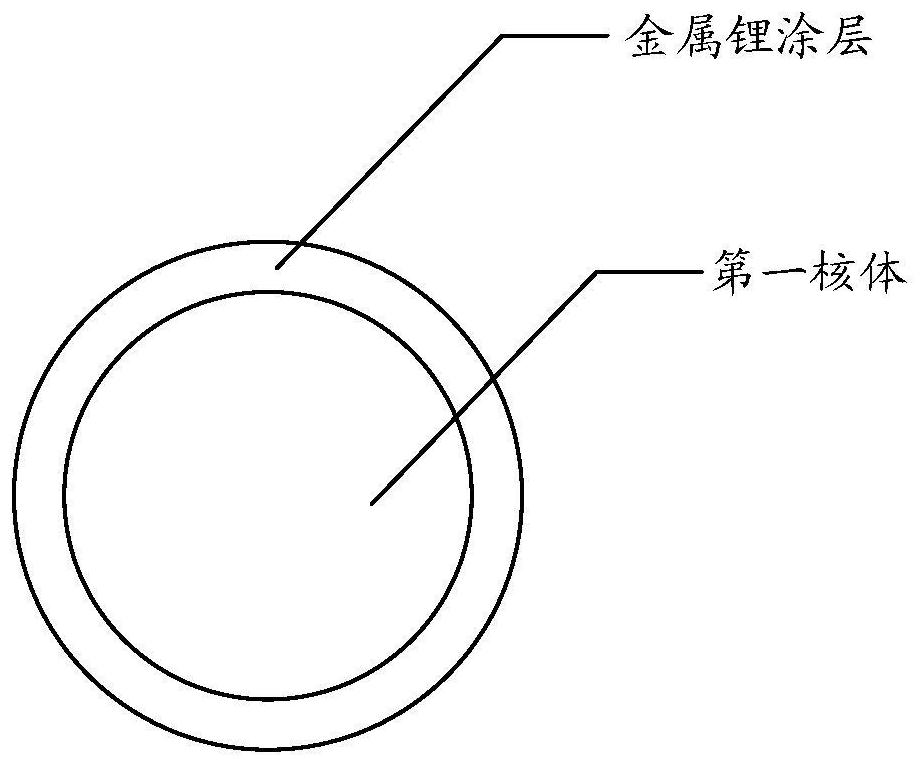

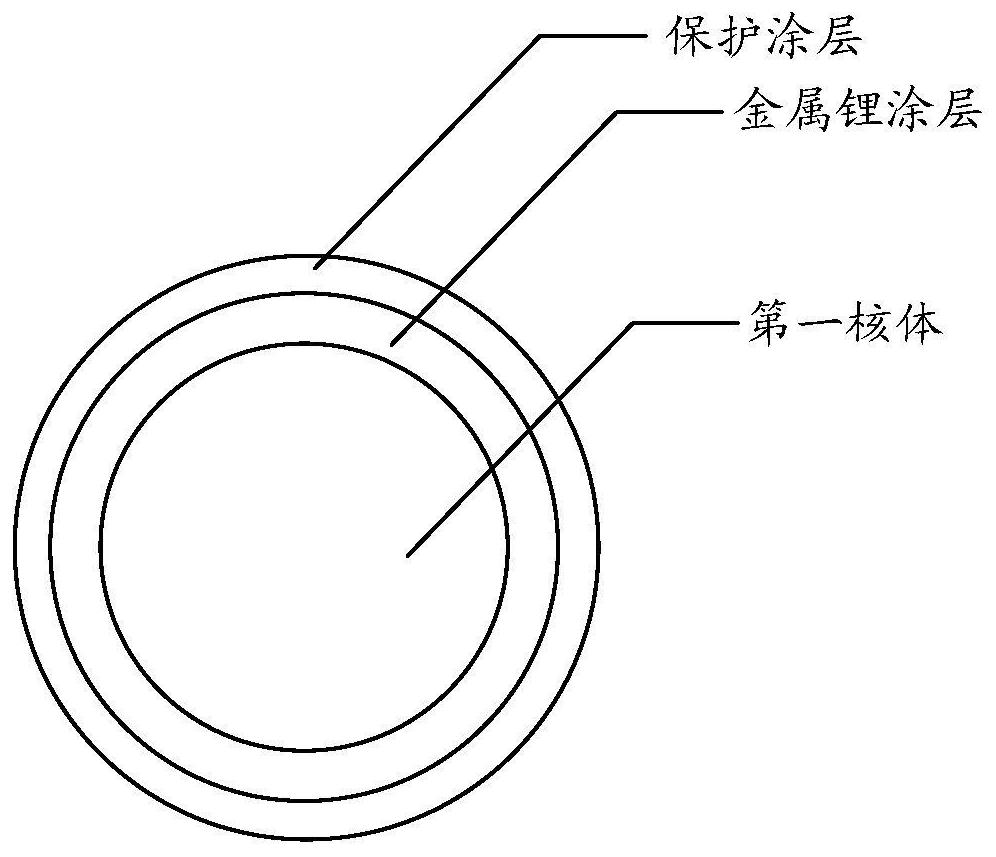

Lithium ion battery electrode material and preparation method thereof

PendingCN112909224AImprove Coulombic efficiencyLower diffusion barrierCell electrodesSecondary cellsMetallic lithiumCharge and discharge

The invention provides a lithium ion battery electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The lithium ion battery electrode material comprises at least one first core body and at least one second core body, a metal lithium coating which is coated on the surface of at least one first core body; and a protective coating which coats the outer side of the metal lithium coating, so that the metal lithium coating is isolated from air. According to the prepared lithium ion battery electrode material provided by the embodiment of the invention, active lithium ions can be effectively supplemented in the chemical reaction of the battery, the active lithium ions consumed by SEI and the like formed in the first charging and discharging process are reduced, and the coulombic efficiency of the battery material is improved. In addition, the metal lithium coating is adopted as a raw material for supplementing lithium ions, so that the diffusion barrier of the lithium ions can be reduced, the transference number of the lithium ions can be increased, and the deintercalation or intercalation efficiency of the lithium ions can be improved, thereby improving the energy density and cycling stability of the lithium ion battery.

Owner:HUAWEI TECH CO LTD

Composite positive electrode material with spring-shaped lamellar structure as well as preparation method and application of composite positive electrode material

PendingCN114050245AImprove structural rigidityImprove conductivityCell electrodesSecondary cellsAluminum IonAluminium-ion battery

The invention provides a composite positive electrode material with a spring-shaped lamellar structure as well as a preparation method and application of the composite positive electrode material. The composite positive electrode material comprises a carbon sheet layer and vanadium trioxide nanoparticles dispersed on the surface of the carbon sheet layer. The invention provides an aluminum ion battery composite positive electrode material with a spring-shaped lamellar structure. The composite positive electrode material adopts a carbon sheet layer as a support skeleton, and is compounded with vanadium trioxide nanoparticles, so the diffusion path of aluminum ions is reduced, and the conductivity of the composite positive electrode material is enhanced; meanwhile, a precursor material is prepared by utilizing a hydrothermal method, and is calcined at high temperature to finally obtain the composite material with the spring-shaped lamellar structure.

Owner:中科南京绿色制造产业创新研究院 +1

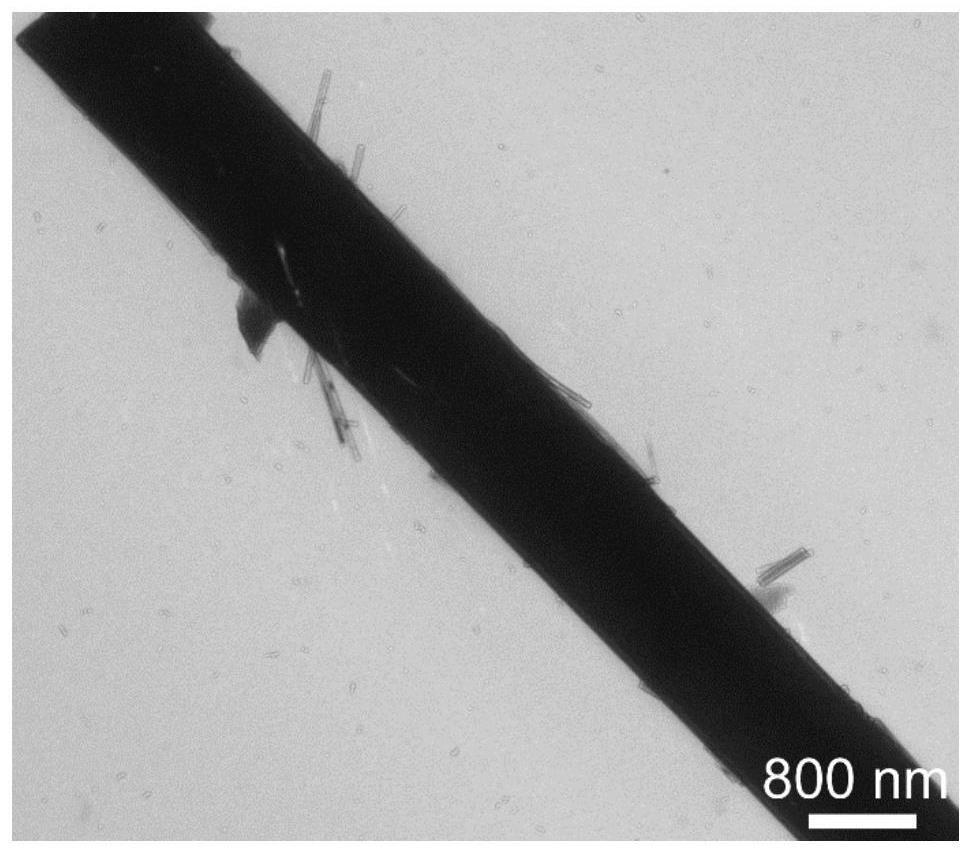

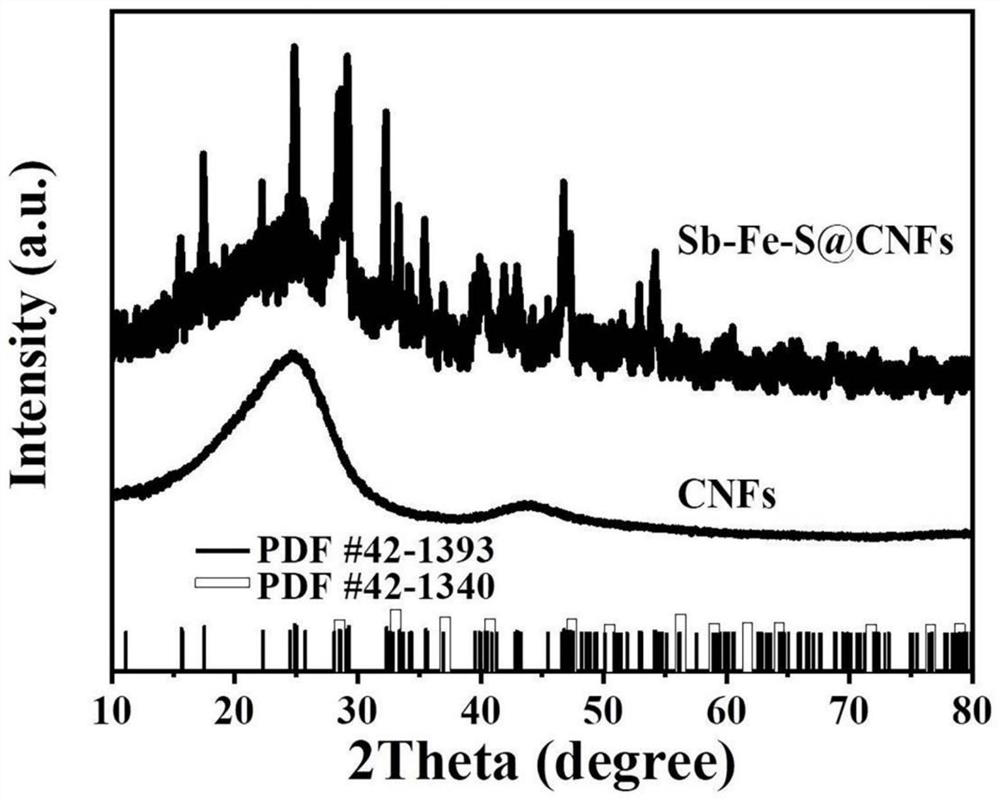

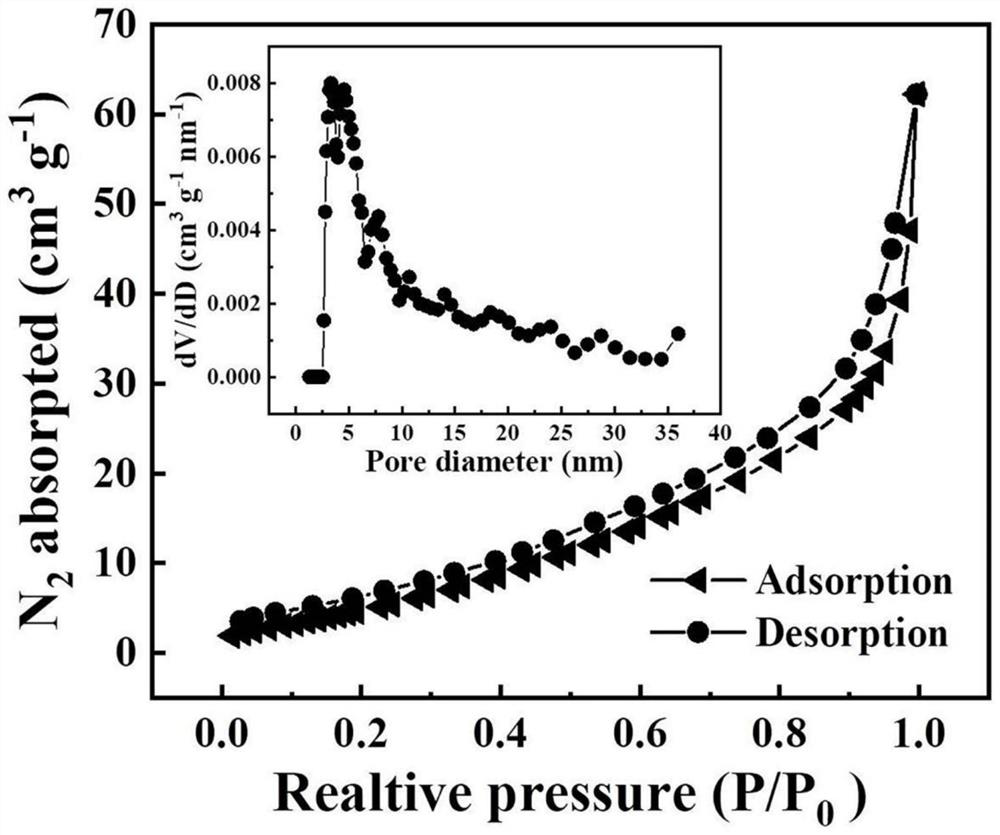

Bimetal sulfide and porous carbon fiber composite material as well as preparation method and application thereof in sodium ion battery

PendingCN114142025AAlleviate particle aggregationMitigation of electrode crushingSecondary cellsNegative electrodesElectrospinningHigh conductivity

The invention relates to the technical field of preparation of sodium ion battery electrode materials, in particular to a bimetallic sulfide and porous carbon fiber composite material, a preparation method thereof and application of the bimetallic sulfide and porous carbon fiber composite material in a sodium ion battery. The preparation method comprises the following steps: packaging bimetallic ions by using electrostatic spinning porous carbon fibers, and carrying out annealing and vulcanization treatment to obtain a bimetallic sulfide and porous carbon fiber composite material; the porous structure can buffer the volume change caused by the reaction of metal sulfide and sodium ions, the strong conductivity of the carbon fiber provides an effective transmission path for electron transfer, and the synergistic effect of the bimetallic sulfide significantly improves the electrochemical performance, so that the carbon fiber has ultra-strong cycling stability when being used as the negative electrode of the sodium ion battery; therefore, the invention provides the sodium ion battery negative electrode material with high stability and high conductivity.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

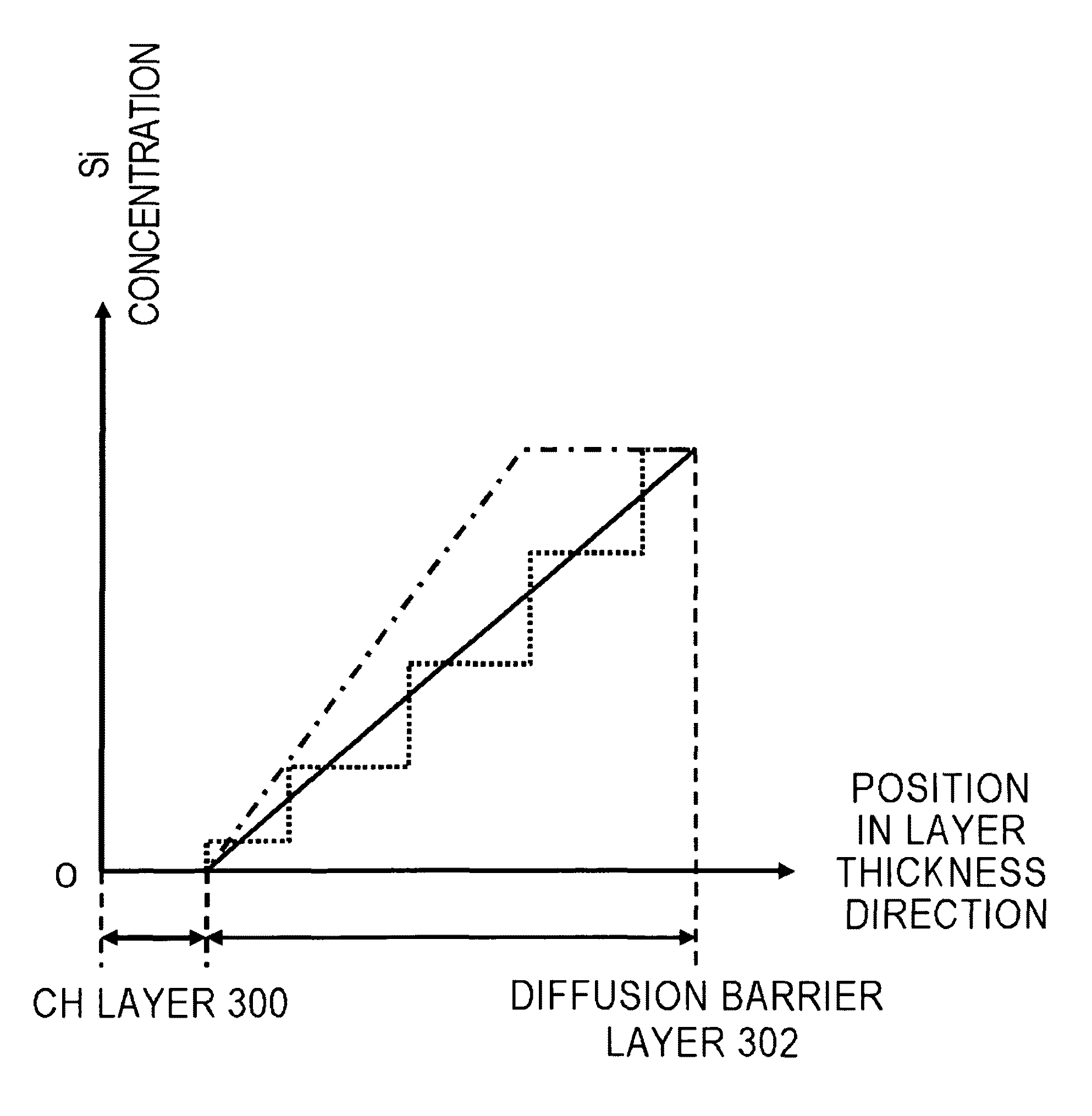

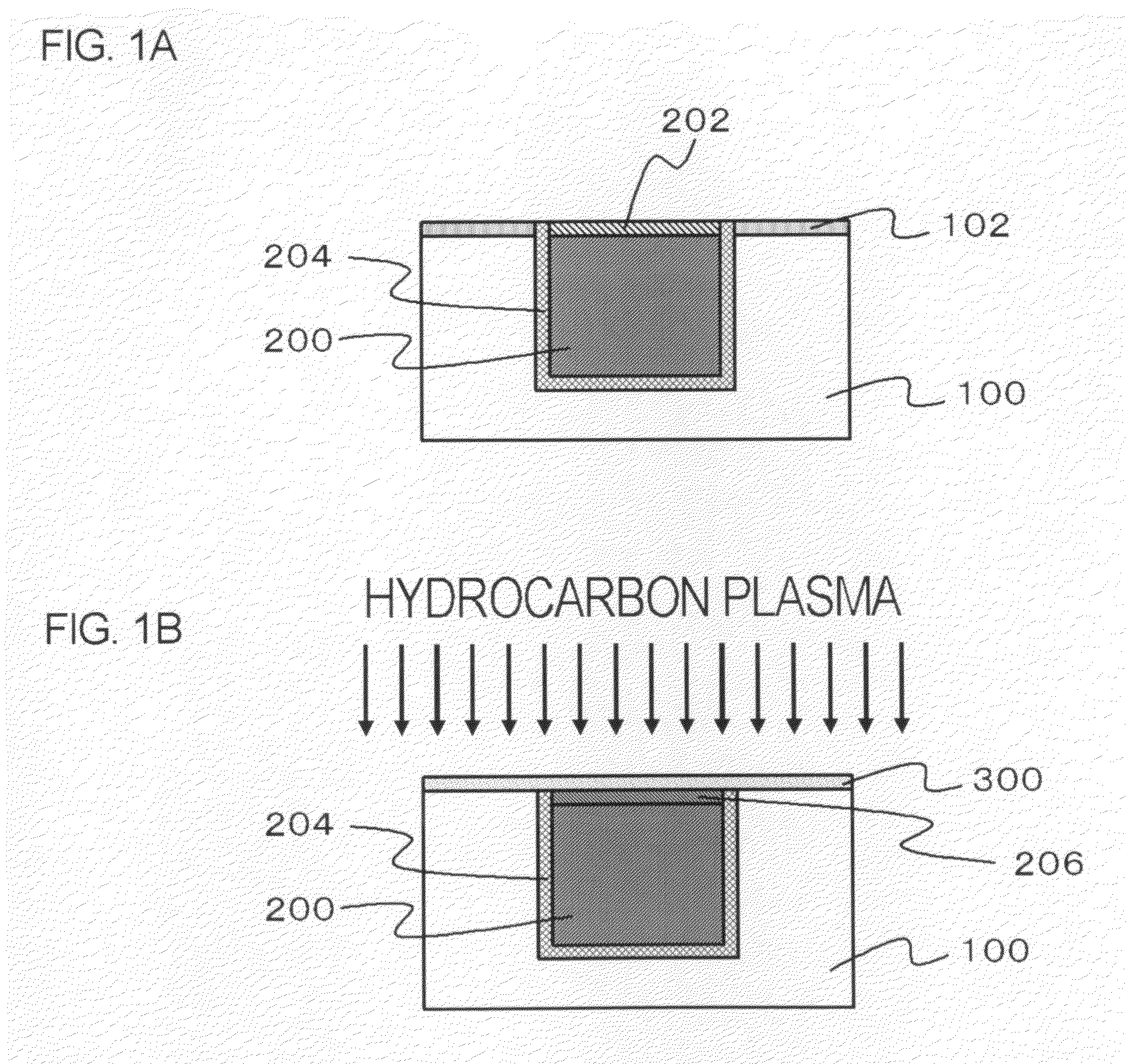

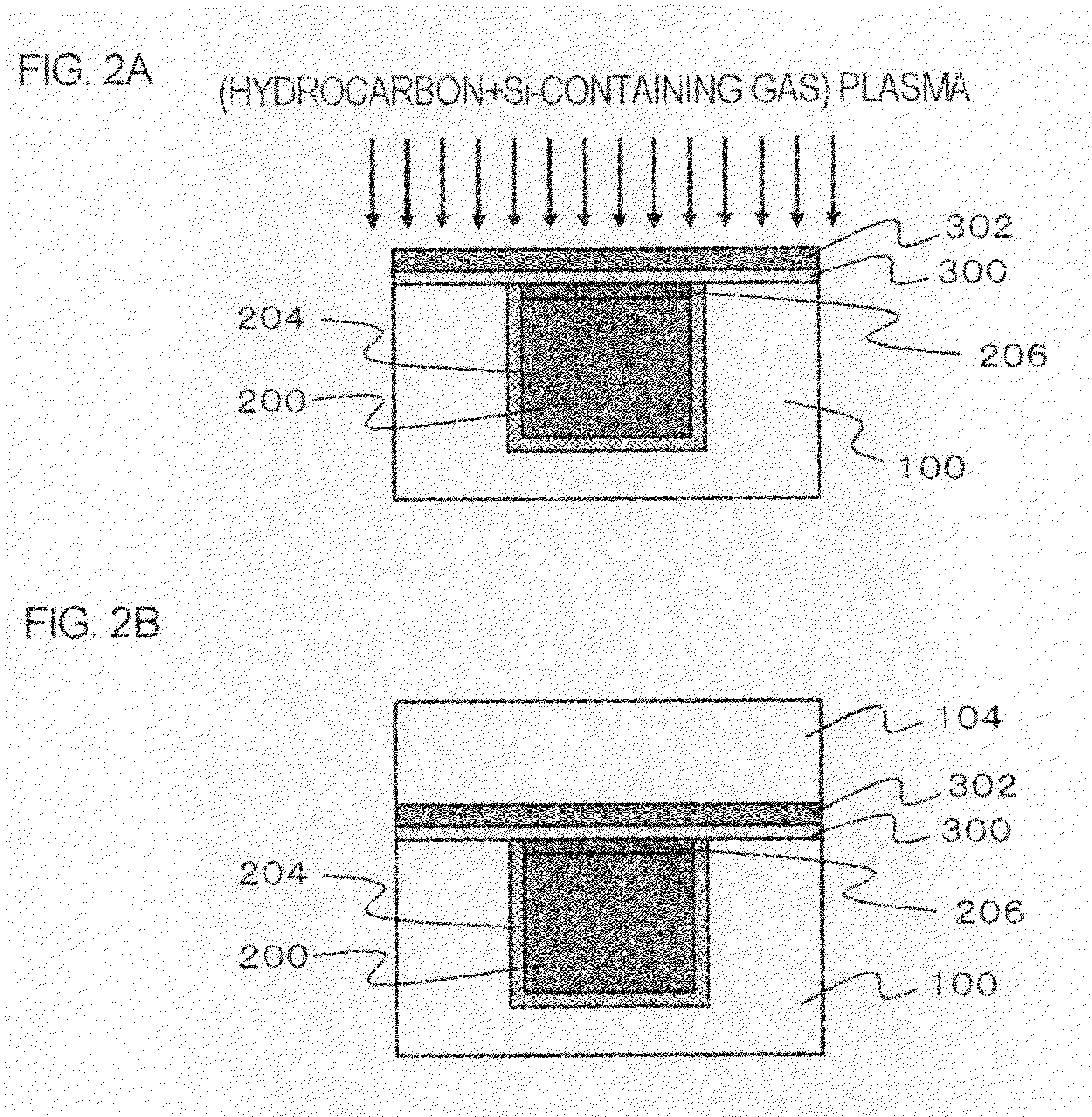

Semiconductor device and method of manufacturing the same

ActiveUS7956467B2Avoid stickingLower diffusion barrierSemiconductor/solid-state device detailsSolid-state devicesDiffusion barrierOrganic polymer

A method includes burying a conductive pattern in an insulating film made of SiOH, SiCOH or organic polymer, treating surfaces of the insulating film and the conductive pattern with plasma which includes a hydrocarbon gas as a treatment gas, and forming a diffusion barrier film, which is formed of an SiCH film, an SiCHN film, an SiCHO film or an SiCHON film, over the insulating film and the conductive pattern with performing a plasma CVD by adding an Si-containing gas to the treatment gas while increasing an addition amount gradually or in a step by step manner.

Owner:RENESAS ELECTRONICS CORP

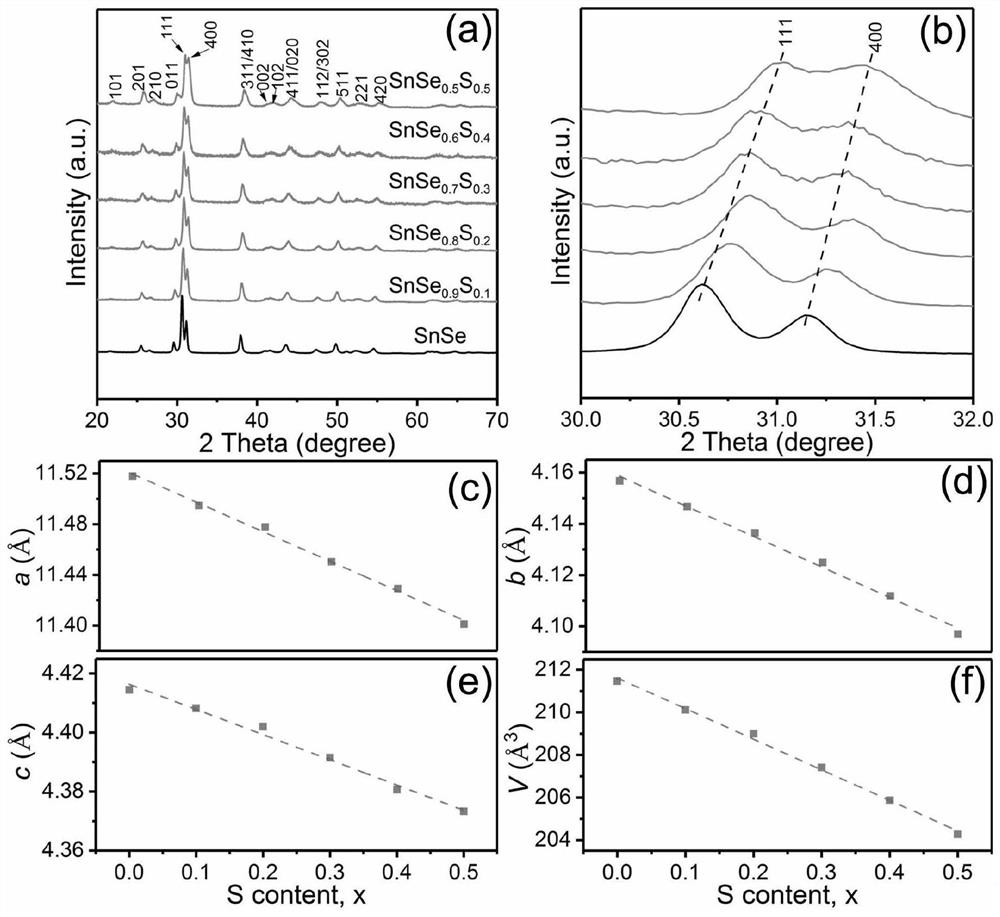

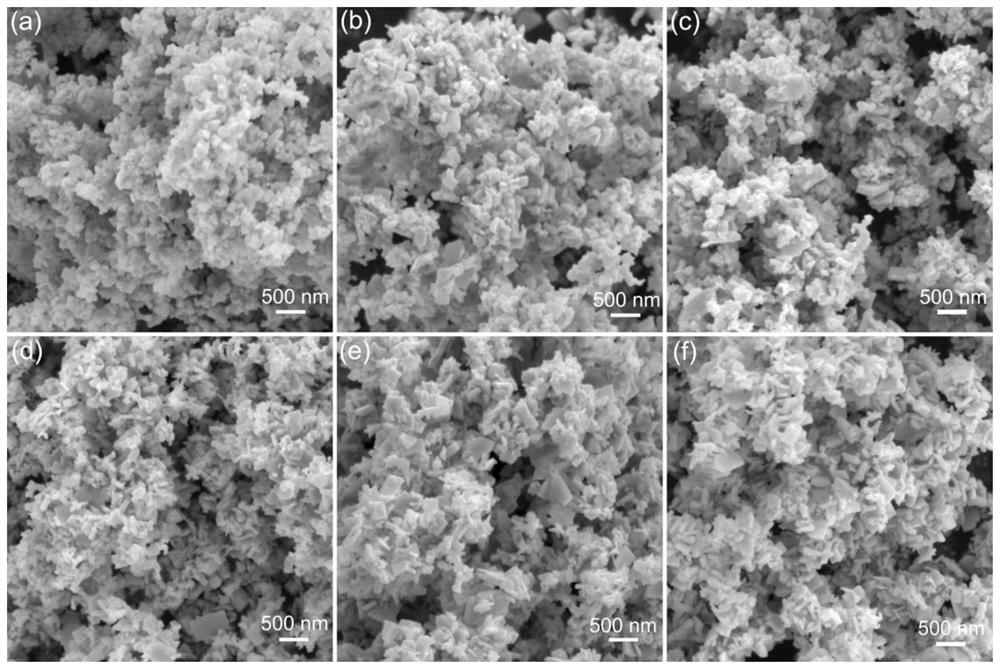

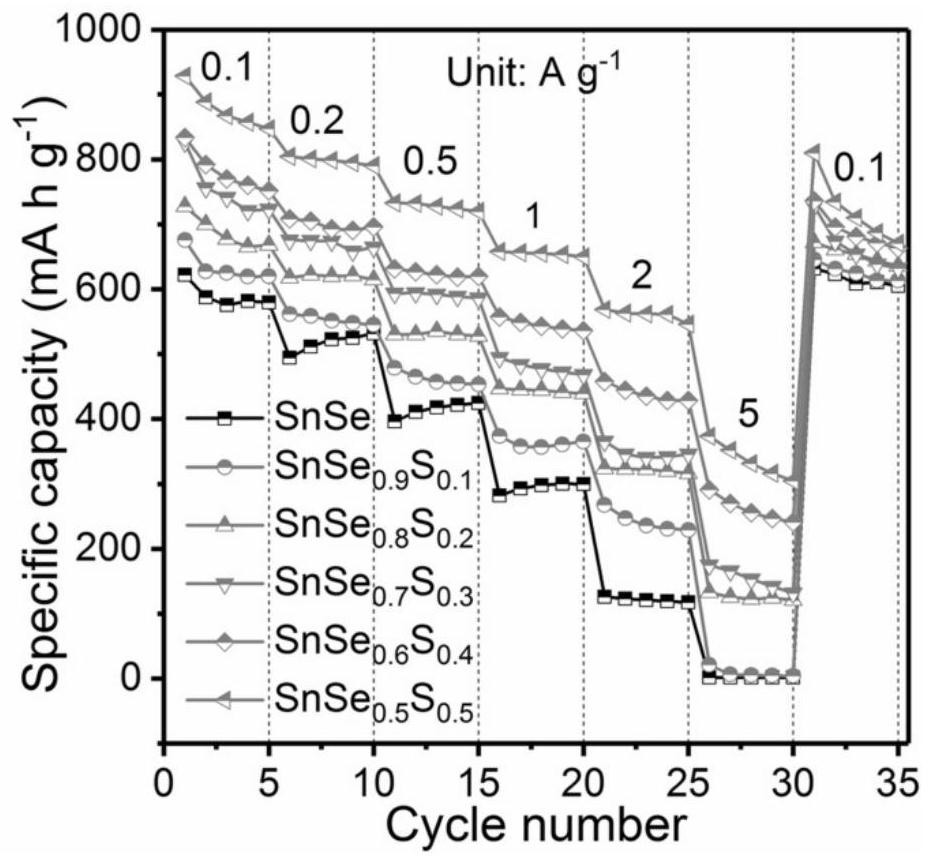

Bifunctional material SnSe1-xSx and preparation method thereof

ActiveCN113394396ASynthesis temperature is lowEasy to operateThermoelectric device manufacture/treatmentCell electrodesFreeze-dryingArgon atmosphere

The invention relates to a preparation method of a bifunctional material SnSe1-xSx, which comprises the following steps: sufficiently reacting SnCl2. 2H2O and NaOH in deionized water according to a molar ratio of 1:10, and stirring in an argon atmosphere to obtain a solution A; preparing a solution B according to the molar ratio of Se to NaBH4 of 1:2.6 in advance; dissolving a certain amount of Na2S.9H2O in a certain amount of water to obtain a solution C; mixing B and C, injecting into the solution A, keeping the stirring speed, and reacting at the boiling temperature; and after the reaction is stopped and cooled, centrifugally collecting, and drying on a freeze dryer to obtain the SnSe1-xSx bifunctional material. The controllable preparation of the nanoscale SnSe1-xSx material is realized, and the electrochemical and thermoelectric properties of the material are optimized at the same time.

Owner:CHONGQING UNIV

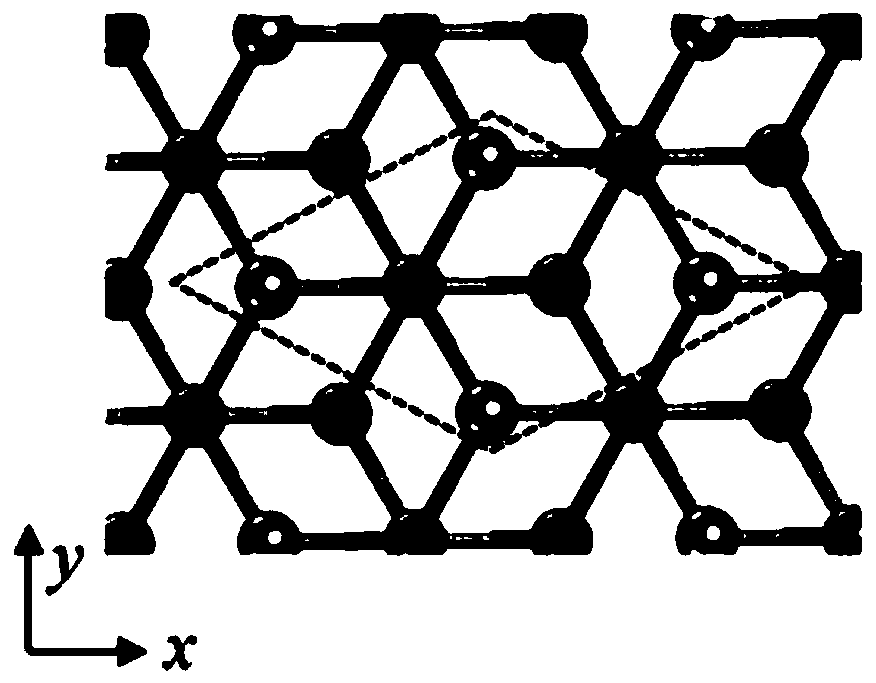

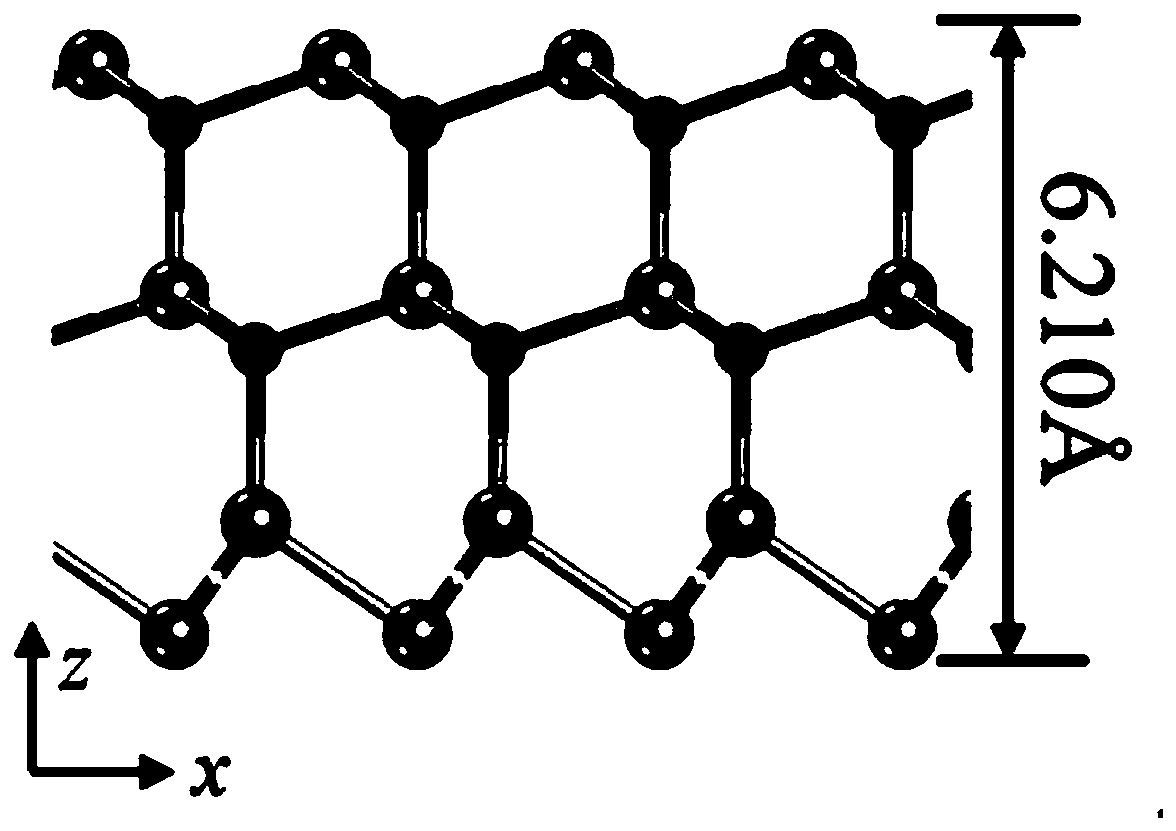

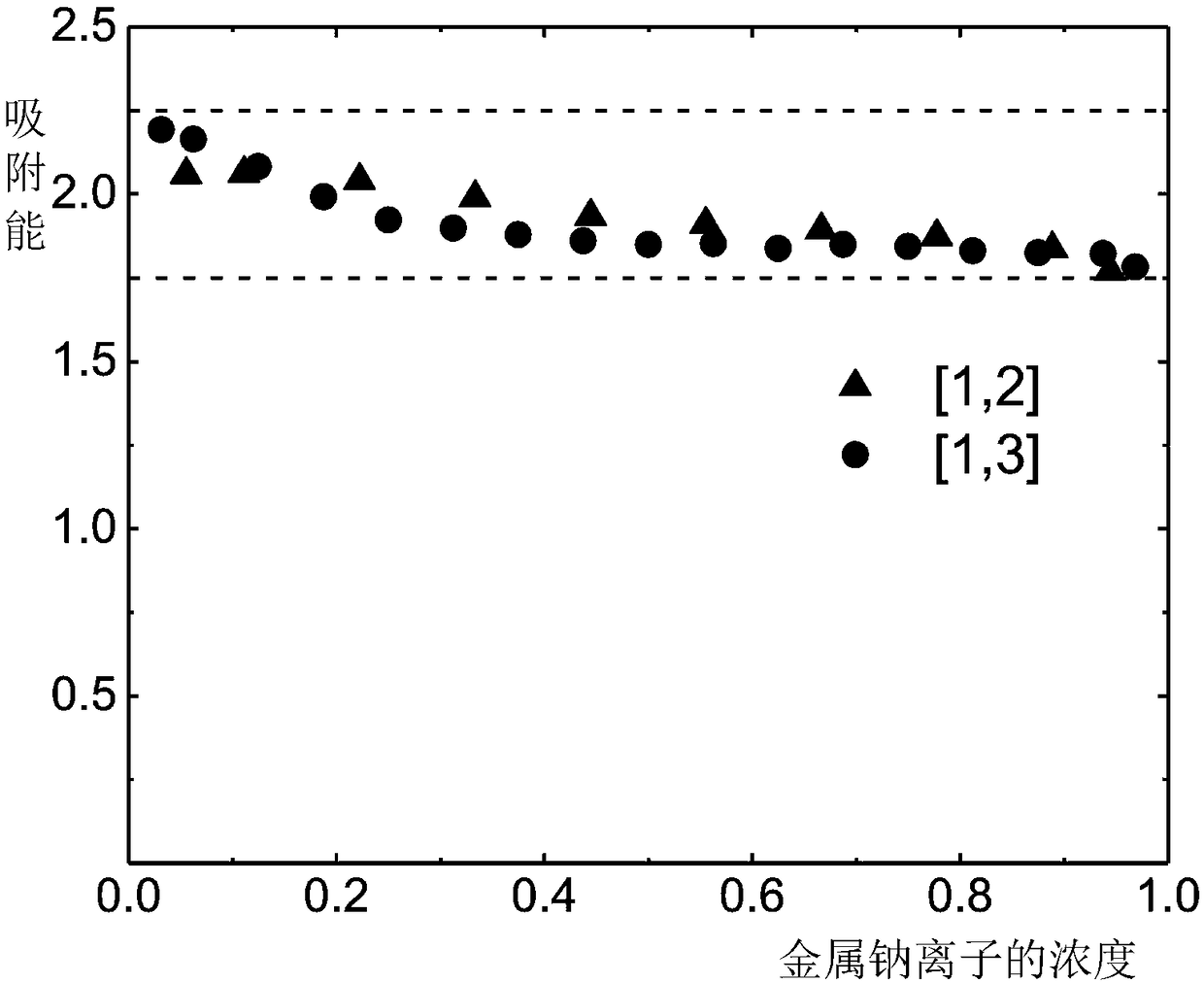

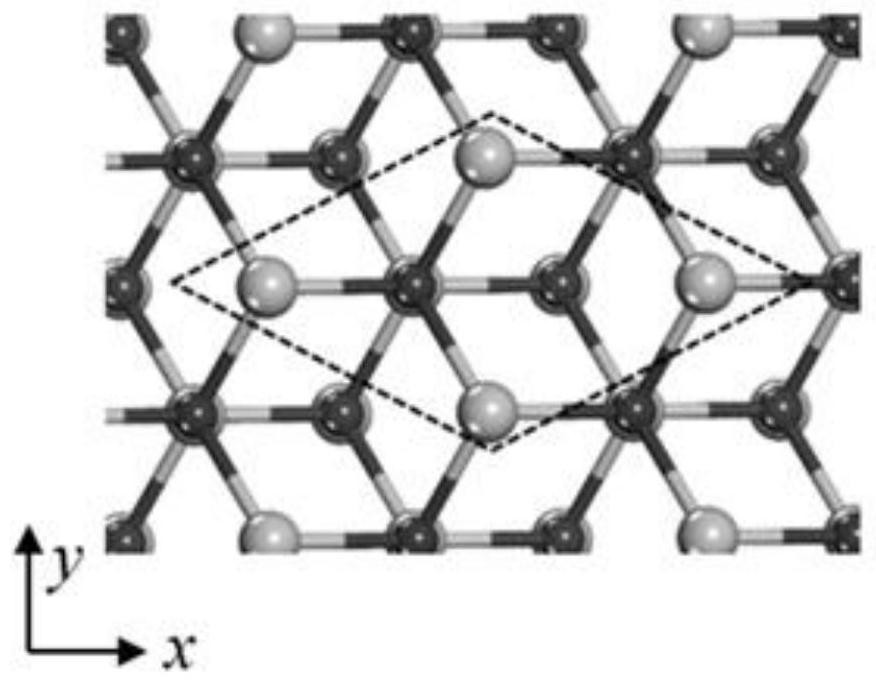

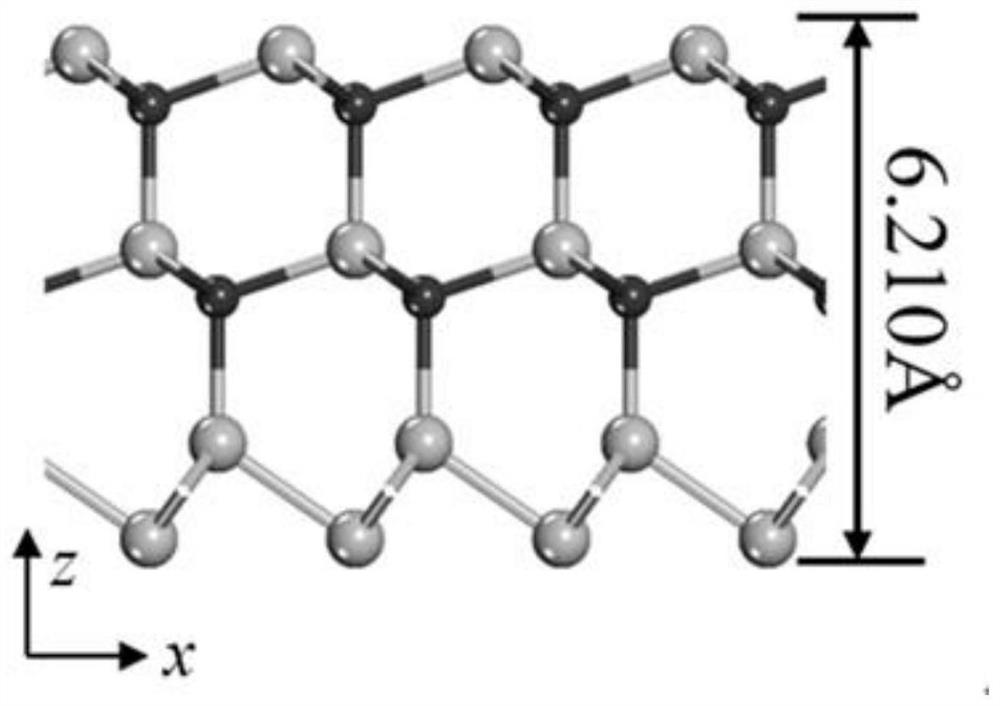

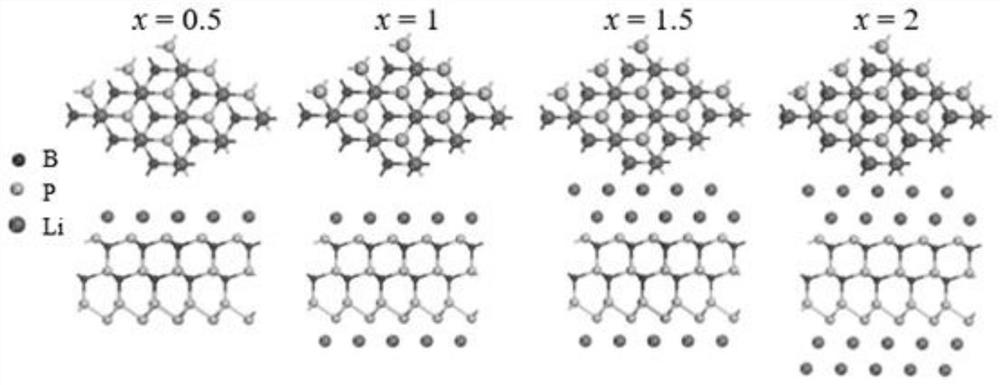

Phosphorus-based positive electrode material for lithium battery and application of phosphorus-based positive electrode material

ActiveCN111554923AEnsure safetyImprove structural stabilitySecondary cellsPositive electrodesChemical physicsSodium-ion battery

The invention discloses a phosphorus-based positive electrode material for a lithium battery and application of the phosphorus-based positive electrode material. The chemical formula of the phosphorus-based positive electrode material is represented by the following formula: BP2, wherein B is a boron element, and P is a phosphorus element. The BP2 is of a single-layer structure and comprises threelayers of graphene-shaped structures, namely, the first layer of graphene-shaped structure, the second layer of graphene-shaped structure and the third layer of graphene-shaped structure in sequence.Both the first layer of graphene and the second layer of graphene consist of B atoms and P atoms in a ratio of 1: 1, and the third layer of graphene consists of P atoms. The material single-layer BP2can become an electrode material with high specific capacity, low diffusion barrier and good structural stability, so that the development of the lithium / sodium ion battery is further promoted, and the electrode material has a good commercial application prospect.

Owner:NANJING UNIV OF POSTS & TELECOMM

A Process for Producing Clean Coal Using Chemical Pre-Treatment and High Shear Reactor

ActiveUS20220033728A1Rapid extraction and removalSmooth connectionSolid fuelsLiquid carbonaceous fuelsThermodynamicsProcess engineering

A method of processing raw coal using activation agents (e.g., solvents and extractants) in a high shear reactor, which creates high shearing forces to break apart the coal and selectively extract and remove contaminants such as ash, sulfur, and other heavy metal impurities resulting in clean, high caloric-value coal.

Owner:CONTROLAMATICS CORP

Negative electrode material, preparation method thereof and sodium ion battery

PendingCN113937281ALower diffusion barrierImprove intrinsic conductivityTitanium sulfidesCobalt sulfidesElectrical batteryCyclic stability

The invention relates to the technical field of battery materials, in particular to a negative electrode material, a preparation method thereof and a sodium ion battery. The negative electrode material comprises a transition metal sulfide, and nitrogen ions and selenium ions doped in the transition metal sulfide. The intrinsic conductivity of the transition metal sulfide can be improved through nitrogen doping, an ion transmission channel can be expanded through introduction of selenium, and through the advantages of nitrogen and selenium anions, the rate capability and cycling stability of the transition metal sulfide negative electrode material are improved while the capacity of the transition metal sulfide negative electrode material is not reduced, so that the negative electrode material has a very good application prospect.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

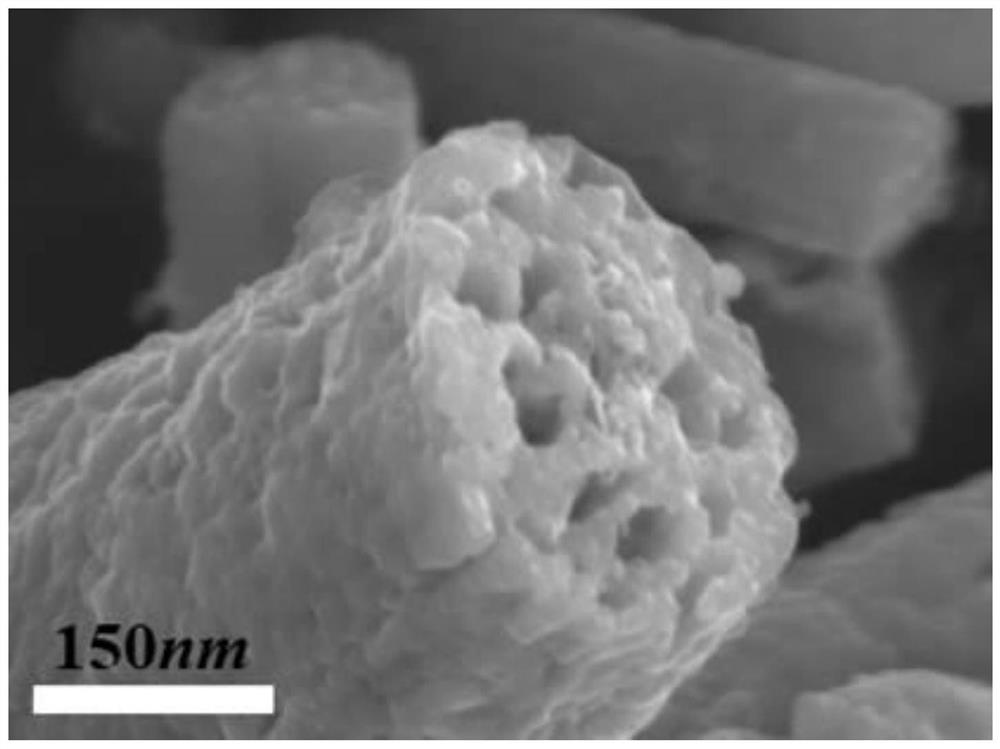

Modified lithium ion battery ternary positive electrode material precursor and preparation method thereof

PendingCN113571693AStable crystal structureSuppression of shufflingCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a modified lithium ion battery ternary positive electrode material precursor, which comprises a matrix and a molybdenum trioxide coating layer on the surface of the matrix, wherein the chemical formula of the ternary positive electrode material precursor is NixCoyMnzMopNbq(OH)2.n MoO3. According to the invention, Nb and Mo ions uniformly doped in a precursor body phase can effectively stabilize the crystal structure of the material, inhibit the mixed arrangement phenomenon of Ni < 2 + > ions and Li < + > in a lithium layer in the charging and discharging process of the ternary material and improve the cycling stability of the ternary positive electrode material, and a formed MoO3 uniform coating layer can reduce the diffusion barrier of Li < + > and accelerate the diffusion of Li < + > from a surface interface to the interior of the bulk phase, so that the rate capability of the positive electrode material is improved. The invention also provides a preparation method of the precursor. The preparation method is short in process, low in cost and suitable for large-scale production.

Owner:ZHUJI PAWA NEW ENERGY

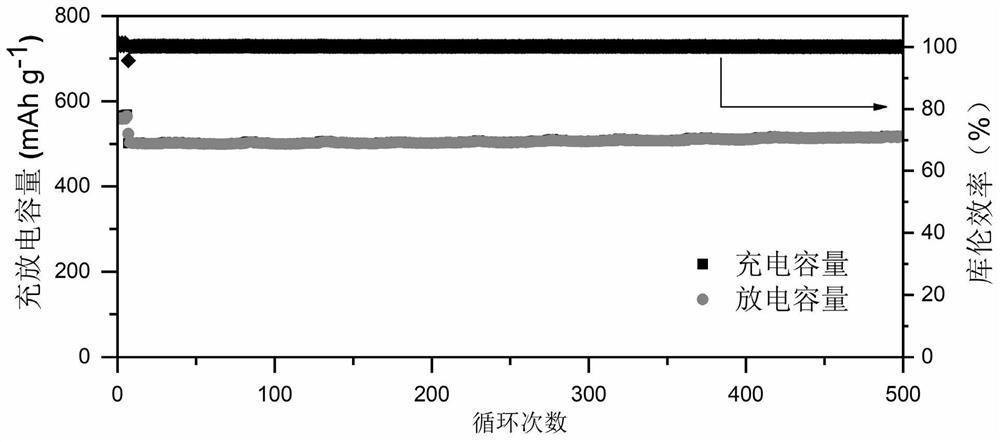

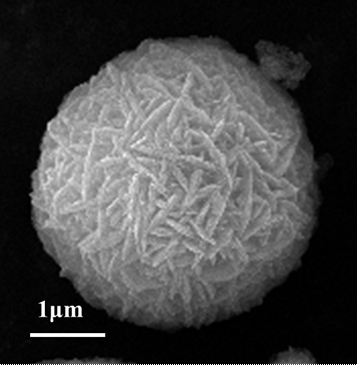

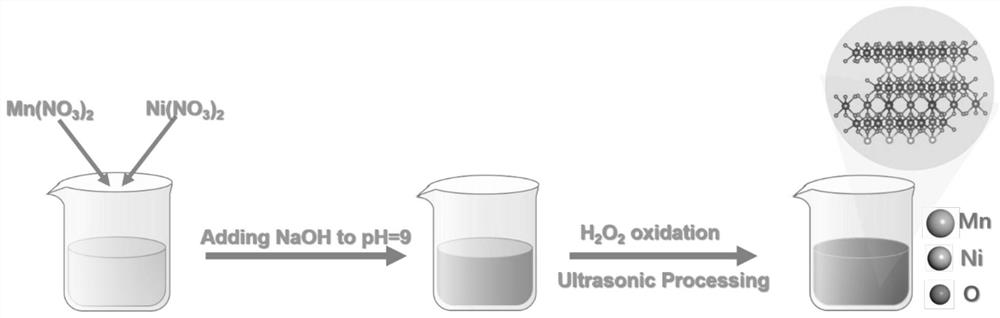

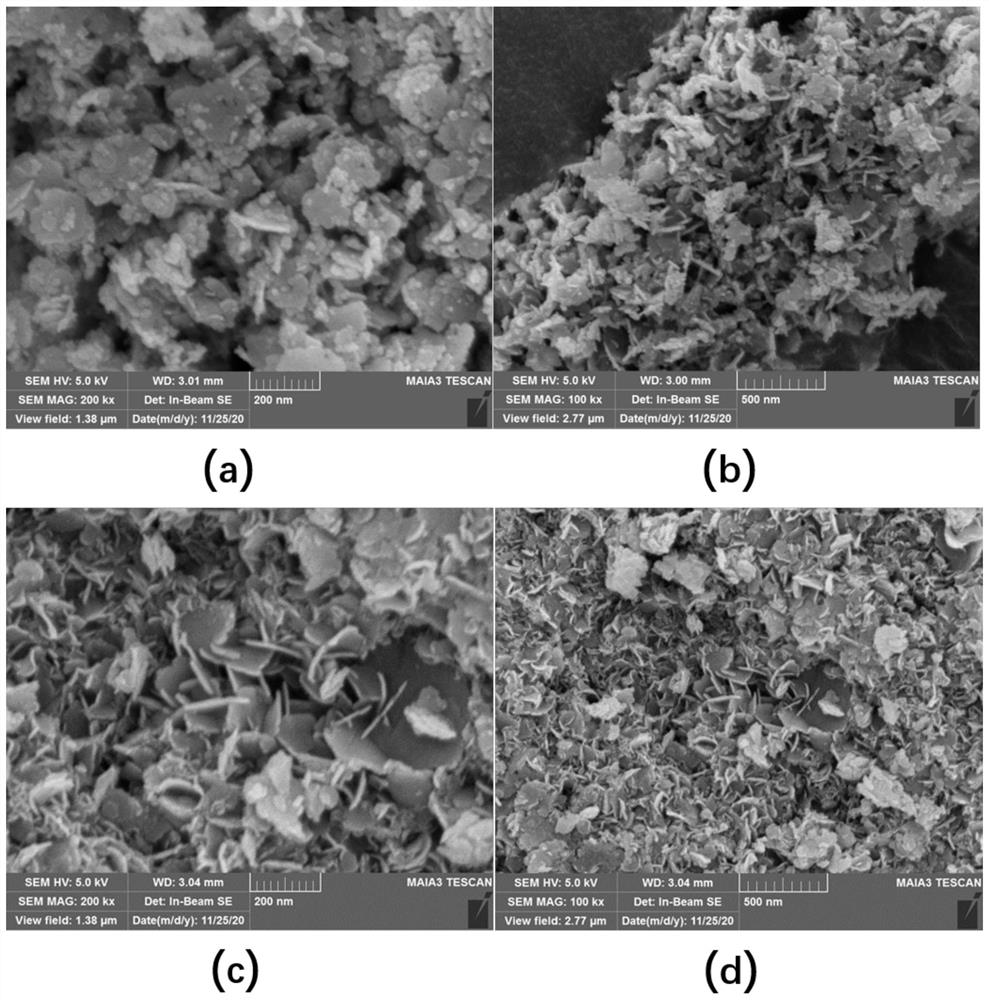

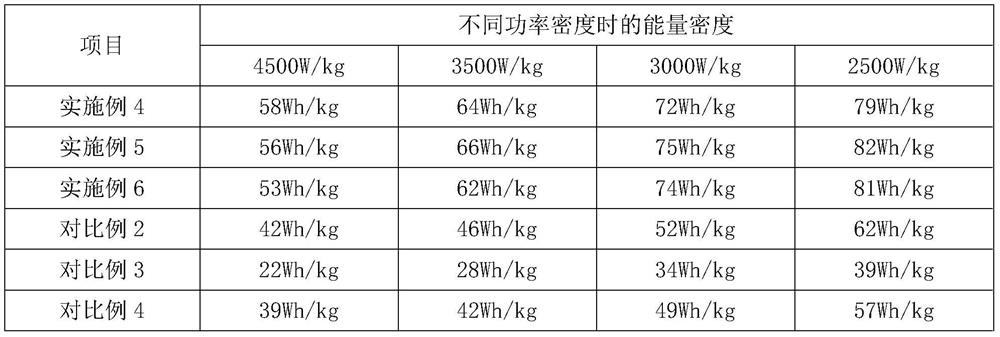

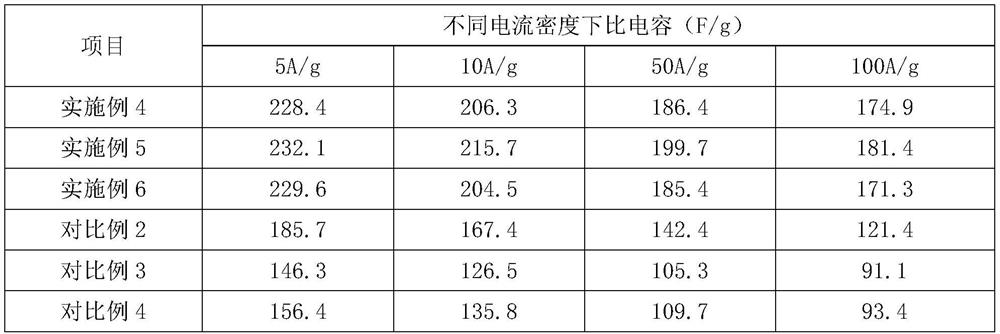

Preparation method and application of electrode material capable of regulating and controlling MnO2 by means of nickel doping induced lattice distortion

PendingCN113628889AIncrease capacitanceImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureMaterials scienceElectrode material

The invention discloses a preparation method and application of an electrode material capable of regulating and controlling MnO2 by means of nickel doping induced lattice distortion, and belongs to the field of material preparation. The performance of MnO2 is regulated and controlled through simple nickel doping induced lattice distortion, so that the electrochemical performance and stability of the manganese dioxide electrode material are improved. The method is free of high temperature and high pressure in preparation, safe in process, simple in step and easy to operate.

Owner:BEIJING UNIV OF CHEM TECH

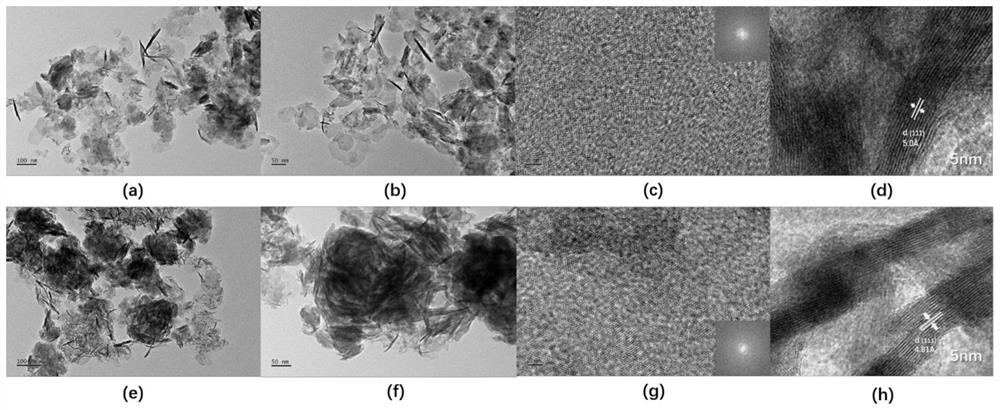

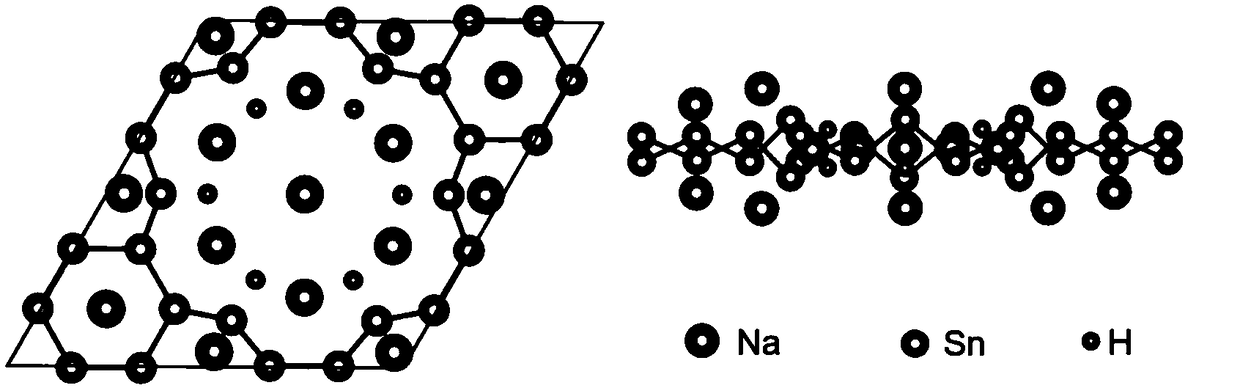

A kind of stanene material and preparation method thereof and battery using the stanene material

ActiveCN107623123BPoor resolutionFast charge and dischargeMaterial nanotechnologyCell electrodesEngineeringTin

Owner:CHAOJING TECH BEIJING CO LTD

A kind of preparation method of zirconia-mullite high porosity ceramic material

ActiveCN107903080BAvoid introducingImprove high temperature resistanceCeramicwareAluminum fluorideMullite

The invention discloses a preparation method of a zirconium oxide-mullite porous ceramic material. The preparation method is characterized in that aluminum oxide and zircon sand are taken as main rawmaterials, yttrium oxide is taken as a stabilizer, aluminum fluoride is taken as an additive, a forming mode combining polyurethane foam dipping and gel solidification is adopted, and the zirconium oxide-mullite porous ceramic material with a needle-shaped mullite whisker structure is prepared through an in-situ synthesis technology; and a solvent in a blank is volatilized and organic substances are split at a high temperature to form a porous structure which has the characteristics of being high in porosity (greater than 80%), uniform in aperture distribution, excellent in high-temperature mechanical property and excellent in thermal impact resistance.

Owner:武汉钢铁有限公司

Preparation method of pressureless sintered boron carbide ceramics based on coarse particle powder

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

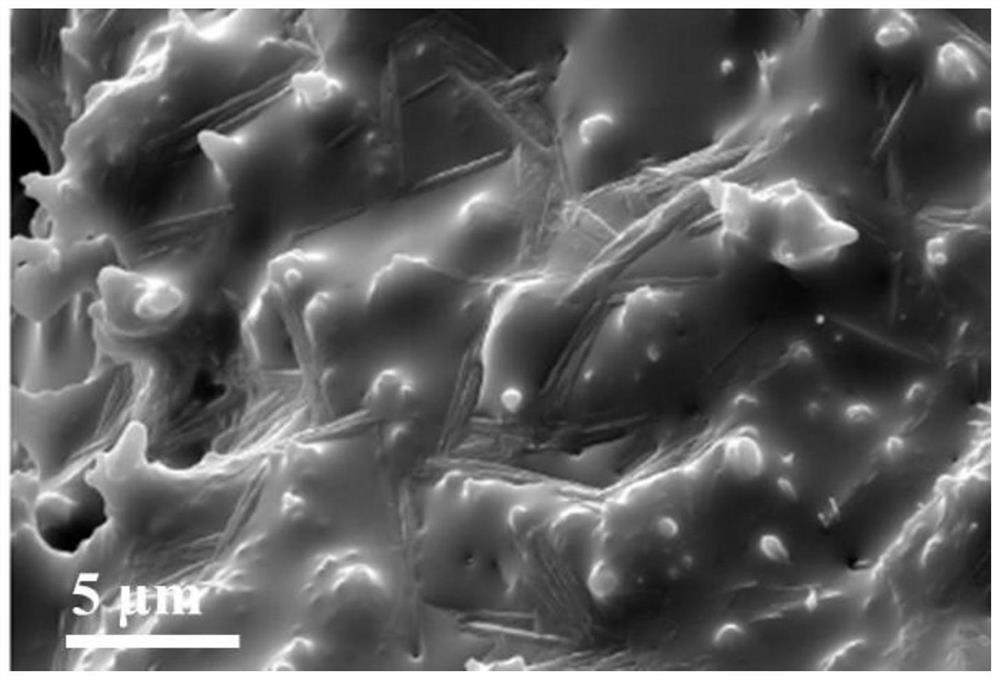

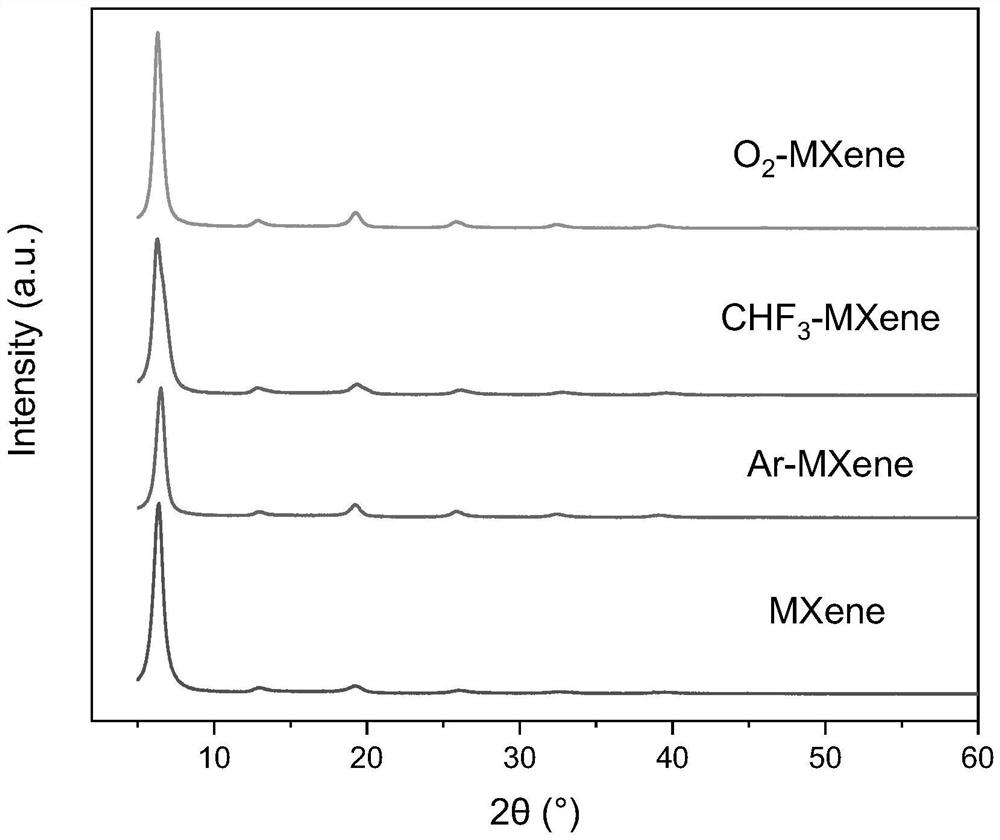

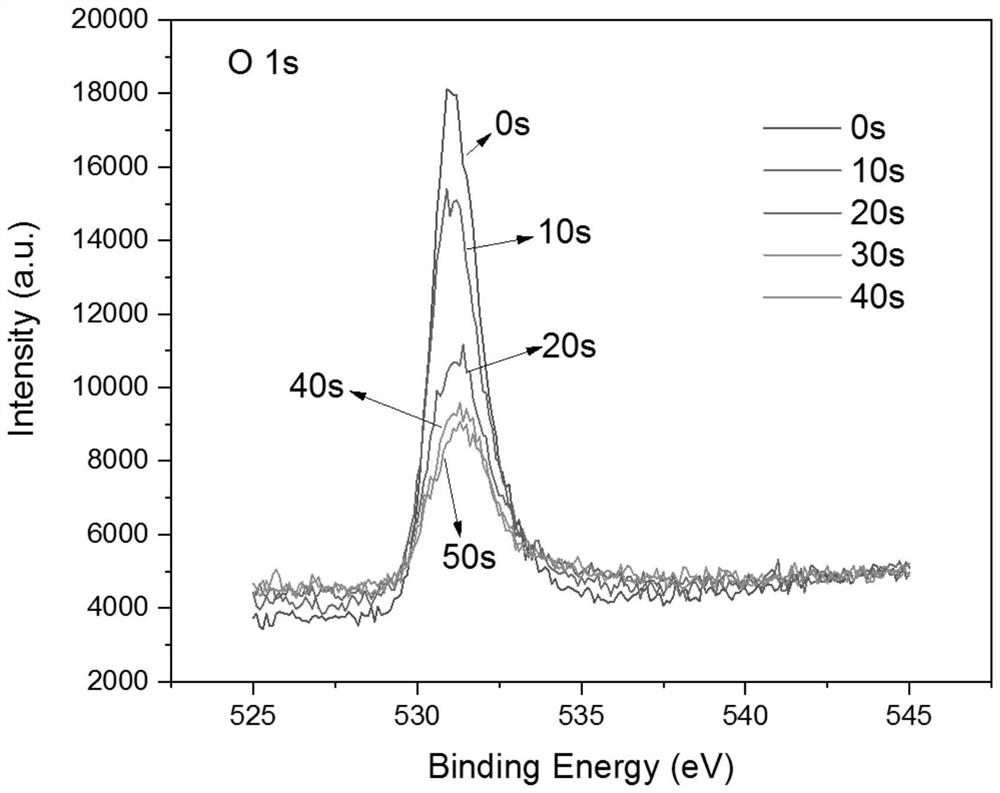

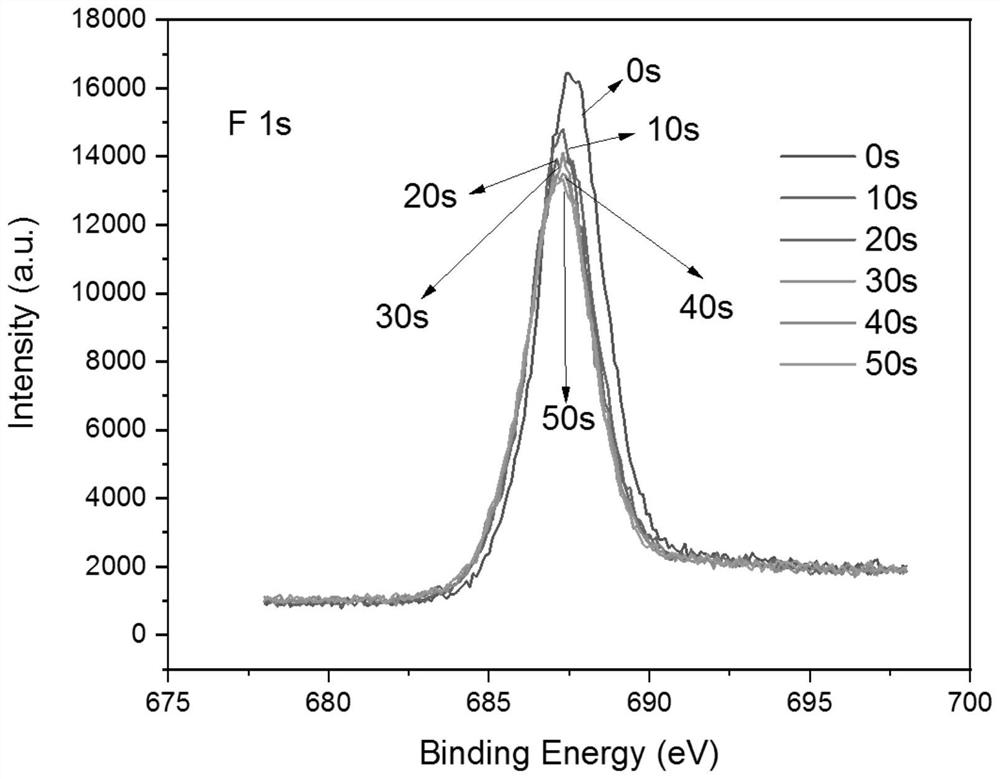

Highly ordered terminated MXene as well as preparation method and application thereof

ActiveCN114843700AIncrease energy densityImprove securityCell seperators/membranes/diaphragms/spacersEngineeringOrganic chemistry

The invention provides highly ordered terminated MXene as well as a preparation method and application thereof, and the preparation method comprises the following steps: preparing an MXene etching product, and then washing and drying to prepare MXene powder; the preparation method comprises the following steps: preparing a dispersion liquid from MXene powder, sequentially carrying out ultrasonic treatment and centrifugal treatment, collecting an upper-layer dispersion liquid, and carrying out suction filtration on the dispersion liquid to prepare an MXene self-supporting membrane; and carrying out plasma etching treatment on the prepared MXene self-supporting film. The terminated MXene can effectively solve the problem that the existing MXene material cannot realize high ordering of a single group.

Owner:SOUTHWEST JIAOTONG UNIV

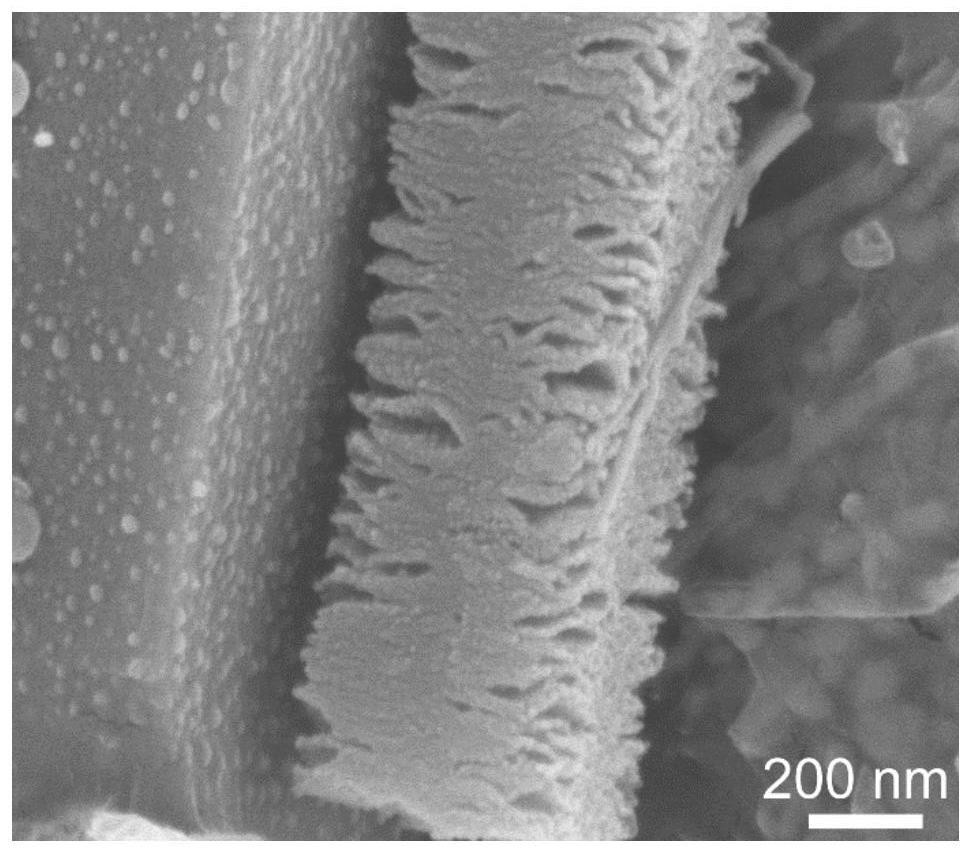

Super capacitor electrode material and preparation method thereof

PendingCN114864303AImprove wettabilityImprove electronic conductivityHybrid capacitor electrodesHybrid/EDL manufactureFiberCarbon fibers

The invention relates to a supercapacitor electrode material and a preparation method thereof, and belongs to the technical field of new energy, and the preparation method comprises the following steps: adding cellulose nanocrystal powder into a polyamic acid solution, heating and annealing in a tubular furnace under a nitrogen atmosphere, and cooling to room temperature; ultrasonically dispersing the carbonized polyimide and ammoniated porous carbon fibers in an ethanol solution to obtain a carbonized polyimide / cellulose-porous carbon fiber composite material; performing ultrasonic dispersion on the mixed solution, a MnSO4 solution and ammonium persulfate in N, N-dimethylformamide to obtain an electrode active material; an electrode active material, carbon black and polytetrafluoroethylene are dispersed in an ethanol solution to form paste, then a foamed nickel current collector is coated with the mixture, and the supercapacitor electrode material is obtained through pressing and drying. The porosity of the material is increased by compounding ammoniated porous carbon fibers on carbonized polyimide / cellulose, and gamma-MnO2 is deposited in situ, so that the energy density of the electrode material is greatly increased.

Owner:YANGZHOU POLYTECHNIC INST

A kind of phosphorus-based cathode material for lithium battery and its application

ActiveCN111554923BEnsure safetyImprove structural stabilitySecondary cellsPositive electrodesChemical physicsElectrical battery

The present invention discloses a phosphorus-based positive electrode material for lithium batteries and its application. The chemical formula of the phosphorus-based positive electrode material is represented by the following formula: BP 2 , where B is boron and P is phosphorus. the BP 2 It is a single-layer structure, including a three-layer graphene-like structure, which is a first-layer graphene-like structure, a second-layer graphene-like structure, and a third-layer graphene-like structure. The first layer of graphene and the second layer of graphene are both composed of B and P atoms in a ratio of 1:1, and the third layer of graphene is composed of P atoms. Single-layer BP of the material of the present invention 2 It can become an electrode material with high specific capacity, low diffusion barrier and good structural stability, which makes the development of lithium / sodium ion batteries further, and has good commercial application prospects.

Owner:NANJING UNIV OF POSTS & TELECOMM

Composite cathode active material and lithium ion secondary battery

ActiveCN105226271BLower diffusion barrierDiffusion fastCell electrodesSecondary cellsSpace groupComposite oxide

The invention provides a composite positive electrode active material and a lithium ion secondary battery. The composite positive electrode active material comprises positive electrode active material particles, and a coating material which is positioned on the external of the positive electrode active material particles for coating the positive electrode active material particles. The positive electrode active material particles are layered lithium composite oxide; the general formula of the layered lithium composite oxide is Li1+xNiaCobM (1-a-b)Y2, wherein x is greater than or equal to minus 0.1 and less than or equal to 0.2; a is greater than or equal to 0 and less than or equal to 1, b is greater than or equal to 0.05 and less than or equal to 1, and a+b is greater than or equal to 0.05 and less than or equal to 1; M is selected from one or more of Mg, Zn, Ga, Ba, Al, Fe, Cr, Sn, V, Mn, Sc, Ti, Nb, Mo or Zr; Y is selected from one or more of O, or F; the bulk structure of the coating material is P4 / mbm space group; and the lithium ion secondary battery comprises the composite positive electrode active material. The lithium ion secondary battery is higher in energy density and better in cycle performance under high voltage.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com