Bifunctional material SnSe1-xSx and preparation method thereof

A technology of bifunctional materials and nanomaterials, applied in the field of preparation of bifunctional materials SnSe1-xSx, can solve problems such as gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

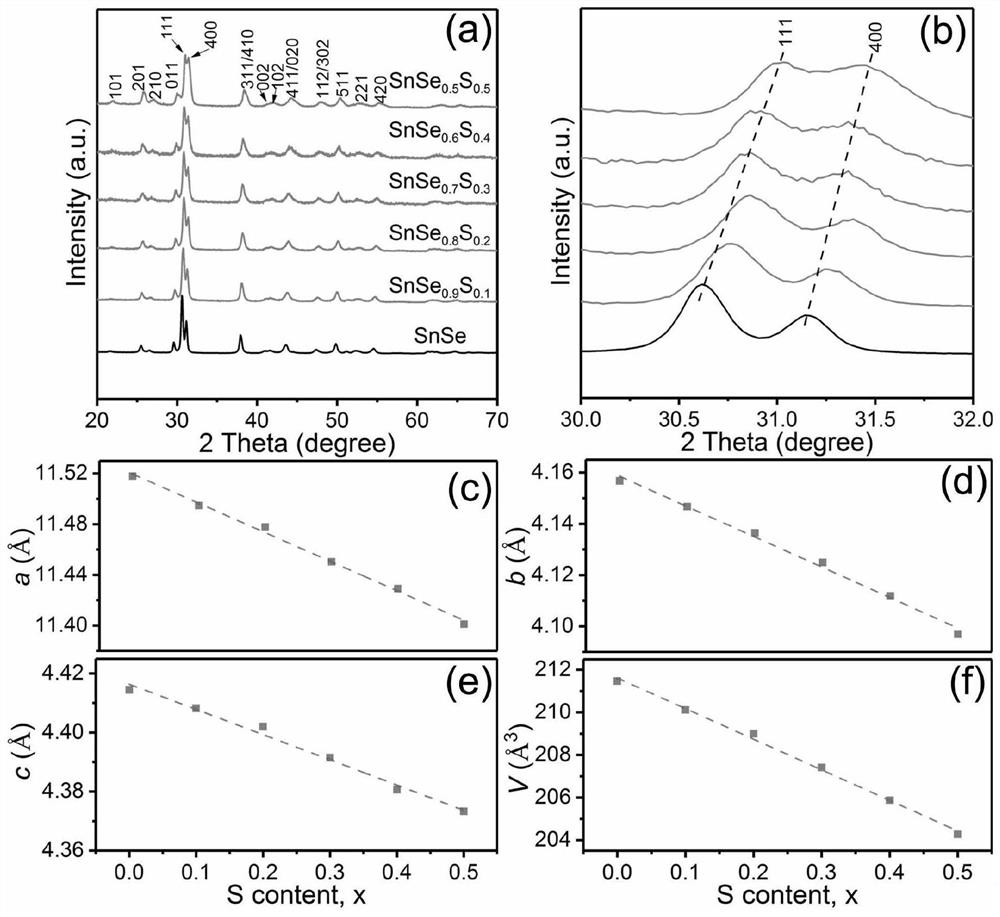

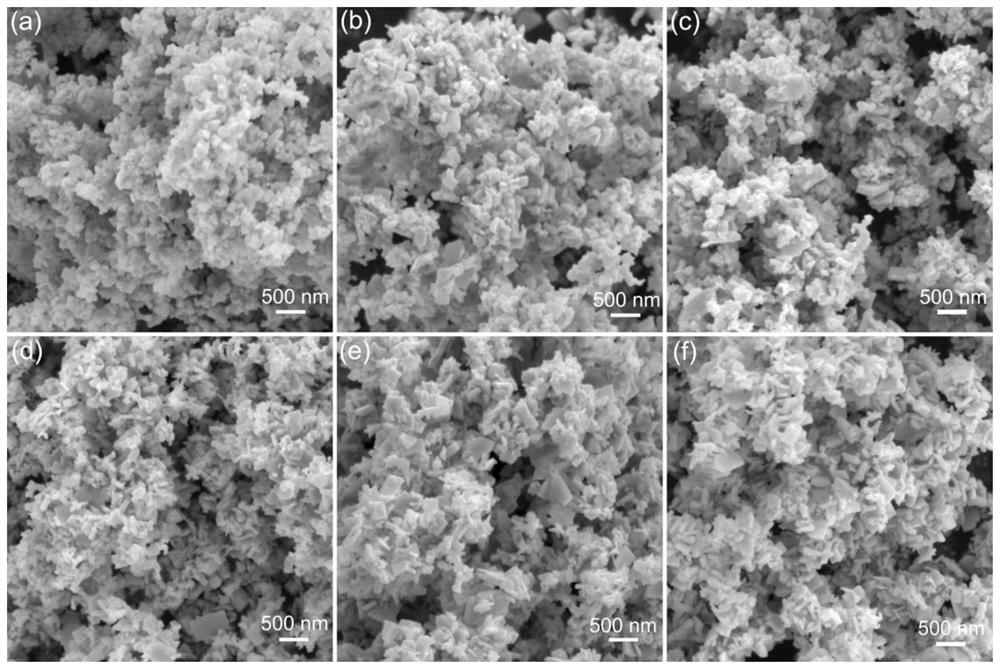

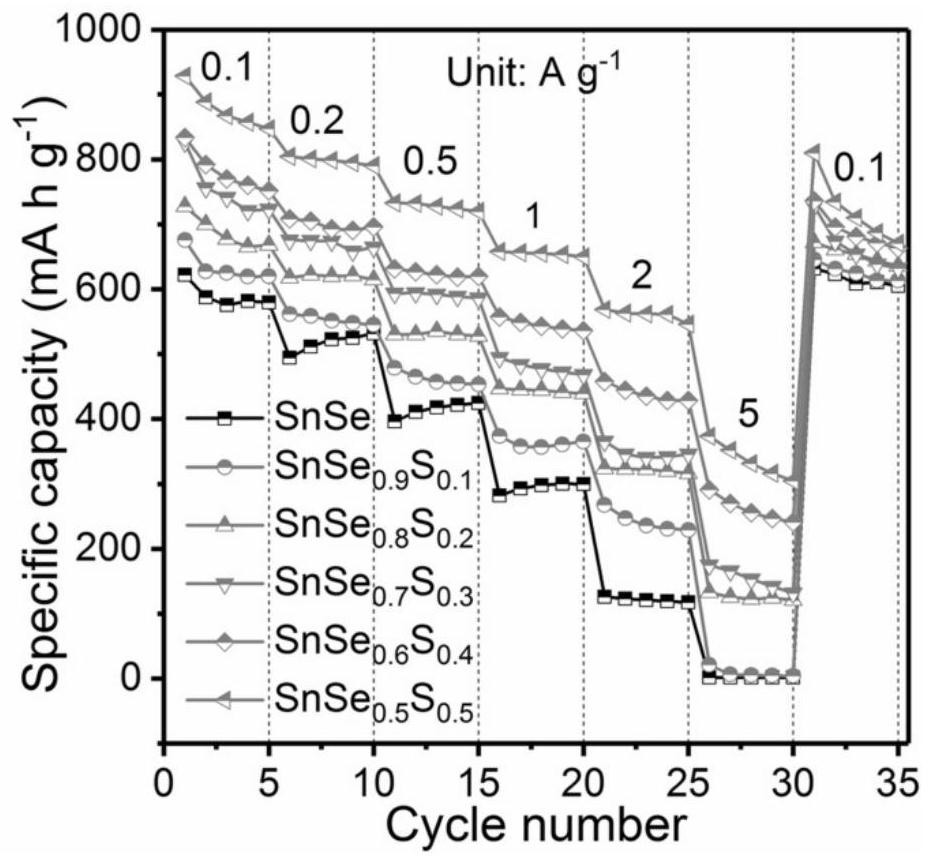

[0023] Embodiment 1: see Figure 1-6 , a bifunctional material SnSe with enhanced electrochemical storage and thermoelectric performance 1- x S x The preparation method, when x=0, concrete steps comprise:

[0024] 1) Take 10mmol SnCl 2 2H 2O was fully reacted with 100mmol NaOH in 50mL deionized water, and stirred at 600r / min under an argon atmosphere to obtain solution A;

[0025] 2) Take 10mmol Se and 26mmol NaBH 4 In 50mL of deionized water, stir with a magnetic stirrer at a stirring speed of 600r / min for 30min to obtain solution B;

[0026] 3) Inject B into solution A, and react for 2 hours at a stirring speed of 600r / min and a temperature of 130°C;

[0027] 4) After the above reaction was stopped and cooled for 30 minutes, the reaction solution was collected by centrifugation and dried on a freeze dryer for 48 hours to obtain the SnSe bifunctional material.

Embodiment 2

[0028] Example 2: see Figure 1-6 , a bifunctional material SnSe with enhanced electrochemical storage and thermoelectric performance 1- x S x The preparation method, when x=0.1, concrete steps comprise:

[0029] 1) Take 10mmol SnCl 2 2H 2 O was fully reacted with 100mmol NaOH in 50mL deionized water, and stirred at 600r / min under an argon atmosphere to obtain solution A;

[0030] 2) Take 9mmol Se and 23.4mmol NaBH 4 In 45mL of deionized water, stir with a magnetic stirrer at a stirring speed of 600r / min for 30min to obtain solution B;

[0031] 3) Take 2mmol Na 2 S·9H 2 O was dissolved in 5 mL of deionized water to obtain solution C;

[0032] 4) Mix B and C and inject into solution A, and react for 2 hours at a stirring speed of 600r / min and a temperature of 130°C;

[0033] 5) After the above reaction is stopped and cooled for 30 minutes, the reaction solution is collected by centrifugation and placed on a freeze dryer for 48 hours to obtain SnSe 0.9 S 0.1 Dual fun...

Embodiment 3

[0034] Embodiment 3: see Figure 1-6 , a bifunctional material SnSe with enhanced electrochemical storage and thermoelectric performance 1- x S x The preparation method, when x=0.2, concrete steps comprise:

[0035] 1) Take 10mmol SnCl 2 2H 2 O was fully reacted with 100mmol NaOH in 50mL deionized water, and stirred at 600r / min under an argon atmosphere to obtain solution A;

[0036] 2) Take 8mmol Se and 20.8mmol NaBH 4 In 40mL deionized water, stir at a stirring speed of 600r / min for 30min under a magnetic stirrer to obtain solution B;

[0037] 3) Take 4mmol Na 2 S·9H 2 O was dissolved in 10 mL of deionized water to obtain solution C;

[0038] 4) Mix B and C and inject into solution A, and react for 2 hours at a stirring speed of 600r / min and a temperature of 130°C;

[0039] 5) After the above reaction is stopped and cooled for 30 minutes, the reaction solution is collected by centrifugation and placed on a freeze dryer for 48 hours to obtain SnSe 0.8 S 0.2 Dual f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com