Modified lithium ion battery ternary positive electrode material precursor and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of uneven distribution of material components, affect the performance of positive electrode materials, and poor consistency of precursors, and achieve cost Low, guaranteed high consistency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

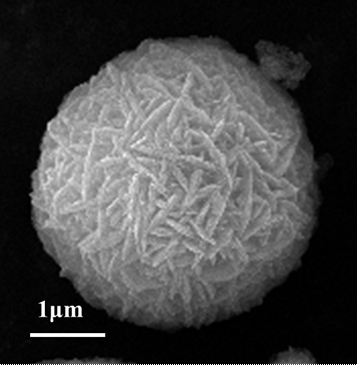

[0038] A modified ternary material precursor, including a substrate and a molybdenum trioxide coating on the surface of the substrate, whose chemical formula is Ni 0.88 co 0.09 mn 0.03 Mo 0.002 Nb 0.002 (OH) 2 • nMoO 3 , the primary particles on the surface of the ternary material precursor are in the form of flakes, the shape of the secondary particles is spherical, the particle size of the secondary particles is 3-6 μm, and the Mo and Nb ions are evenly distributed in the matrix bulk phase structure. The molybdenum oxide coating is 3% of the mass of the base material.

[0039] A method for preparing the aforementioned modified ternary material precursor, which is specifically prepared through the following steps:

[0040](1) Prepare 3mol / L nickel sulfate solution, 3mol / L cobalt sulfate solution and 3mol / L manganese sulfate solution according to the molecular formula of the ternary precursor and the preparation amount of the ternary precursor; The cobalt solution and t...

Embodiment 2

[0045] A modified ternary material precursor preparation method, comprising the steps of:

[0046] (1) Prepare 5mol / L nickel sulfate solution, 5mol / L cobalt sulfate solution and 5mol / L manganese sulfate solution according to the molecular formula of the ternary precursor and the preparation amount of the ternary precursor. solution and manganese sulfate solution (Ni:Co:Mn=88:9:3) were uniformly mixed in the first reaction kettle, and NaOH solution (7 mol / L) and NH 3 •H 2 O solution (7 mol / L) was sent to the first reactor in parallel flow through the metering pump for nucleation and co-precipitation reaction, the stirring speed was controlled at 480 rpm, the reaction temperature was 55 °C, and the pH value was adjusted at 12.5-12.8 , the ammonia value was 13-18 g / L, and the co-precipitation reaction time was controlled to be 2.5 h until uniform fine nano-crystal nuclei were formed, and the D50 of the nuclei was 80 nm;

[0047] (2) Pass the unreacted slurry in the first reacto...

Embodiment 3

[0051] A modified ternary material precursor preparation method, comprising the steps of:

[0052] (1) According to the molecular formula of the ternary precursor and the preparation amount of the ternary precursor, prepare 5.5 mol / L nickel sulfate solution, cobalt sulfate solution and manganese sulfate solution, and the nickel sulfate solution, cobalt sulfate solution and manganese sulfate solution according to ( Ni:Co:Mn=88:9:3) were uniformly mixed, and at the same time NaOH solution (7 mol / L) and NH 3 •H 2 O solution (7 mol / L) was sent to the first reactor in parallel flow through the metering pump for nucleation and co-precipitation reaction, the stirring speed was controlled at 450 rpm, the pH value was adjusted at 12.5-12.8, and the reaction temperature was 50 °C , the ammonia value is 13-18 g / L, and the co-precipitation reaction time is controlled to be 2 hours until uniform fine nano-crystal nuclei are formed, and the D50 of the crystal nuclei is 80 nm;

[0053] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com