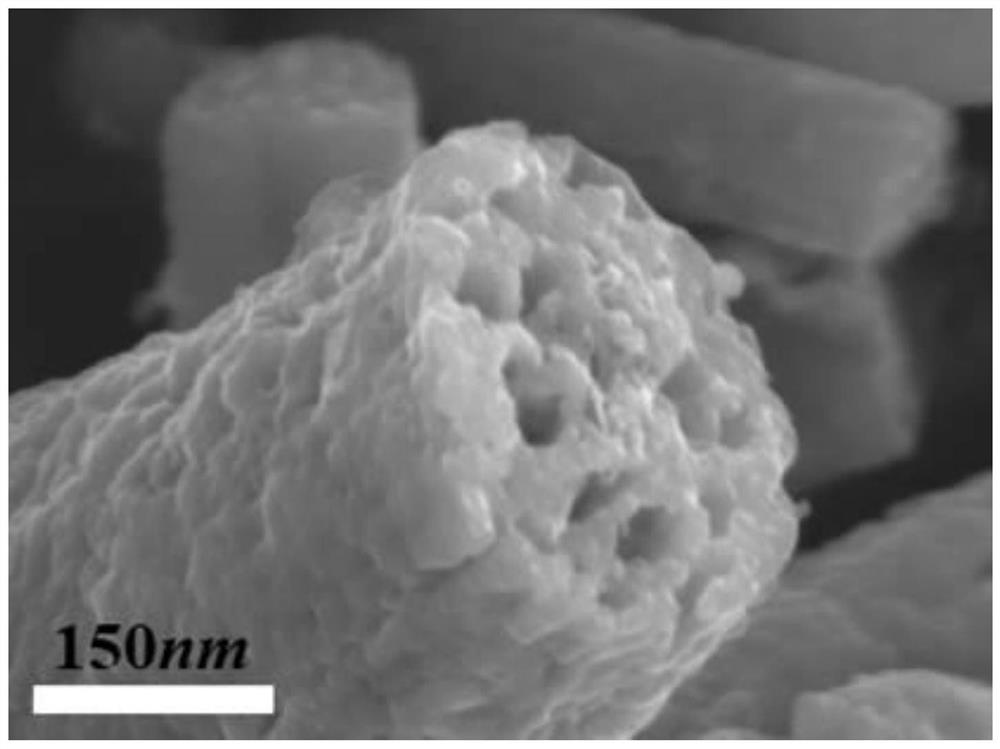

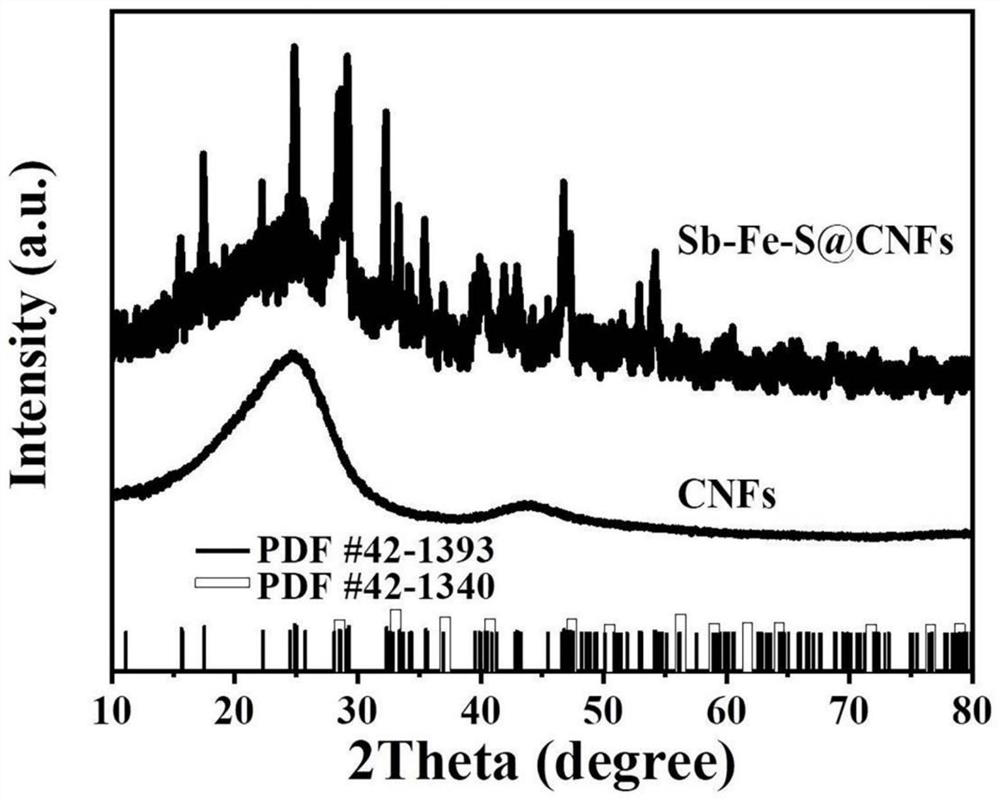

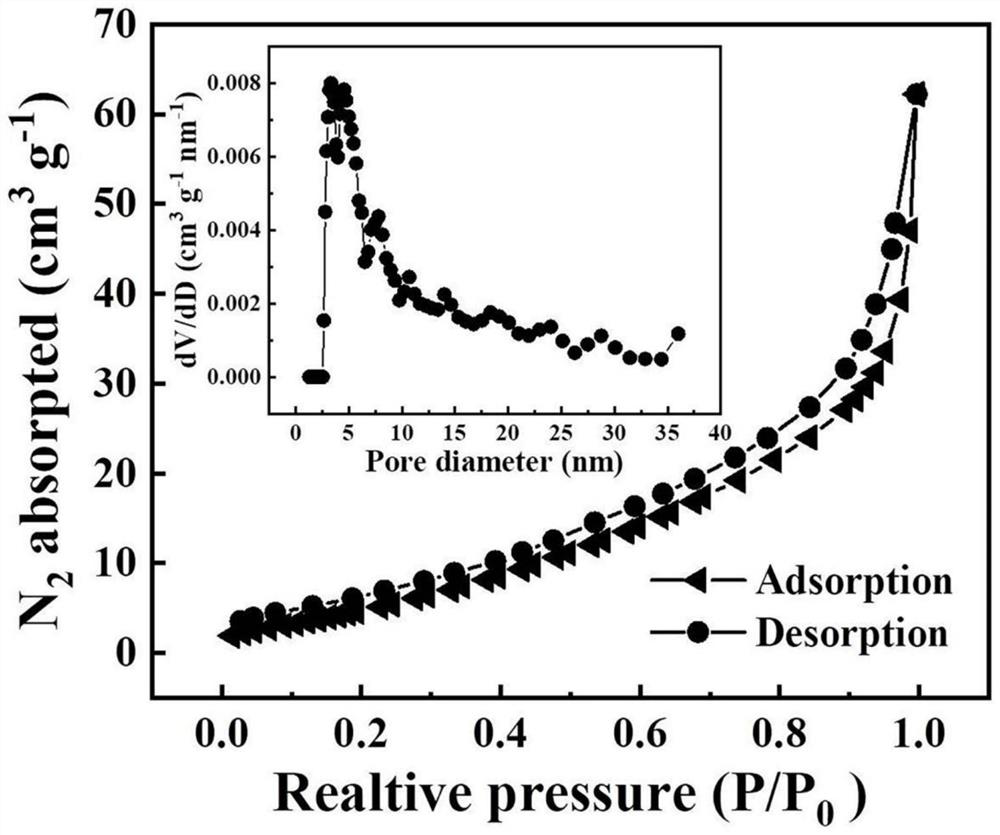

Bimetal sulfide and porous carbon fiber composite material as well as preparation method and application thereof in sodium ion battery

A technology of porous carbon fiber and sodium ion battery, which is applied in the direction of secondary battery, battery electrode, fiber chemical characteristics, etc. It can solve the problems of material structure collapse, slow charge and discharge rate, and large volume change, so as to maintain stability and ease electrode The effect of crushing and uniform fiber size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of bimetallic sulfide@porous carbon fiber composite material comprises the following steps:

[0043] (1) Put polyacrylonitrile and methyl methacrylate in N,N'-dimethylformamide, stir at 30°C for 12 hours to form a transparent solution, and obtain a mixed solution;

[0044] Wherein, the mass ratio of polyacrylonitrile to N,N'-dimethylformamide is 10:100; the mass ratio of methyl methacrylate to polyacrylonitrile is 60:100;

[0045] (2) Add iron acetamidoacetonate and antimony potassium tartrate to the mixed solution of step (1), and keep stirring for 10 hours to obtain a spinning solution;

[0046] Wherein, the mol ratio of ferric acetamidoacetonate and antimony potassium tartrate is 1:1;

[0047] (3) Electrospinning the spinning solution in step (2) to obtain electrospun nanofibers;

[0048] Among them, the electrospinning conditions are: using an electrospinning needle with an inner diameter of 0.4mm, advancing at a voltage of 17kV and a receiv...

Embodiment 2

[0052] The preparation method of bimetallic sulfide@porous carbon fiber composite material comprises the following steps:

[0053] (1) Put polyacrylonitrile and methyl methacrylate in N,N'-dimethylformamide, stir at 20°C for 18 hours to form a transparent solution, and obtain a mixed solution;

[0054] Wherein, the mass ratio of polyacrylonitrile to N,N'-dimethylformamide is 8:100; the mass ratio of methyl methacrylate to polyacrylonitrile is 80:100;

[0055] (2) Add iron acetamidoacetonate and antimony potassium tartrate to the mixed solution of step (1), and keep stirring for 15 hours to obtain a spinning solution;

[0056] Wherein, the mol ratio of ferric acetamidoacetonate and antimony potassium tartrate is 1:1;

[0057] (3) Electrospinning the spinning solution in step (2) to obtain electrospun nanofibers;

[0058] Among them, the electrospinning conditions are: using an electrospinning needle with an inner diameter of 1.15mm, advancing at a voltage of 22kV and a receiv...

Embodiment 3

[0062] The preparation method of bimetallic sulfide@porous carbon fiber composite material comprises the following steps:

[0063] (1) Put polyacrylonitrile and methyl methacrylate in N,N'-dimethylformamide, stir at 80°C for 5 hours to form a transparent solution, and obtain a mixed solution;

[0064] Wherein, the mass ratio of polyacrylonitrile to N,N'-dimethylformamide is 14:100; the mass ratio of methyl methacrylate to polyacrylonitrile is 40:100;

[0065] (2) Add iron acetamidoacetonate and antimony potassium tartrate to the mixed solution of step (1), and continue stirring for 5 hours to obtain a spinning solution;

[0066] Wherein, the mol ratio of ferric acetamidoacetonate and antimony potassium tartrate is 1:1;

[0067] (3) Electrospinning the spinning solution in step (2) to obtain electrospun nanofibers;

[0068] Among them, the electrospinning conditions are: using an electrospinning needle with an inner diameter of 0.27mm, advancing at a voltage of 13kV and a rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com