Lithiation covalent organic framework composite polymer electrolyte as well as preparation and application thereof

A covalent organic framework and composite polymer technology, applied in the field of electrochemistry, can solve the problems of battery energy density improvement, high density, low intrinsic ionic conductivity, etc., to reduce potential barriers, improve interaction, and improve conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of lithiated covalent organic framework composite polymer electrolyte, the steps are as follows:

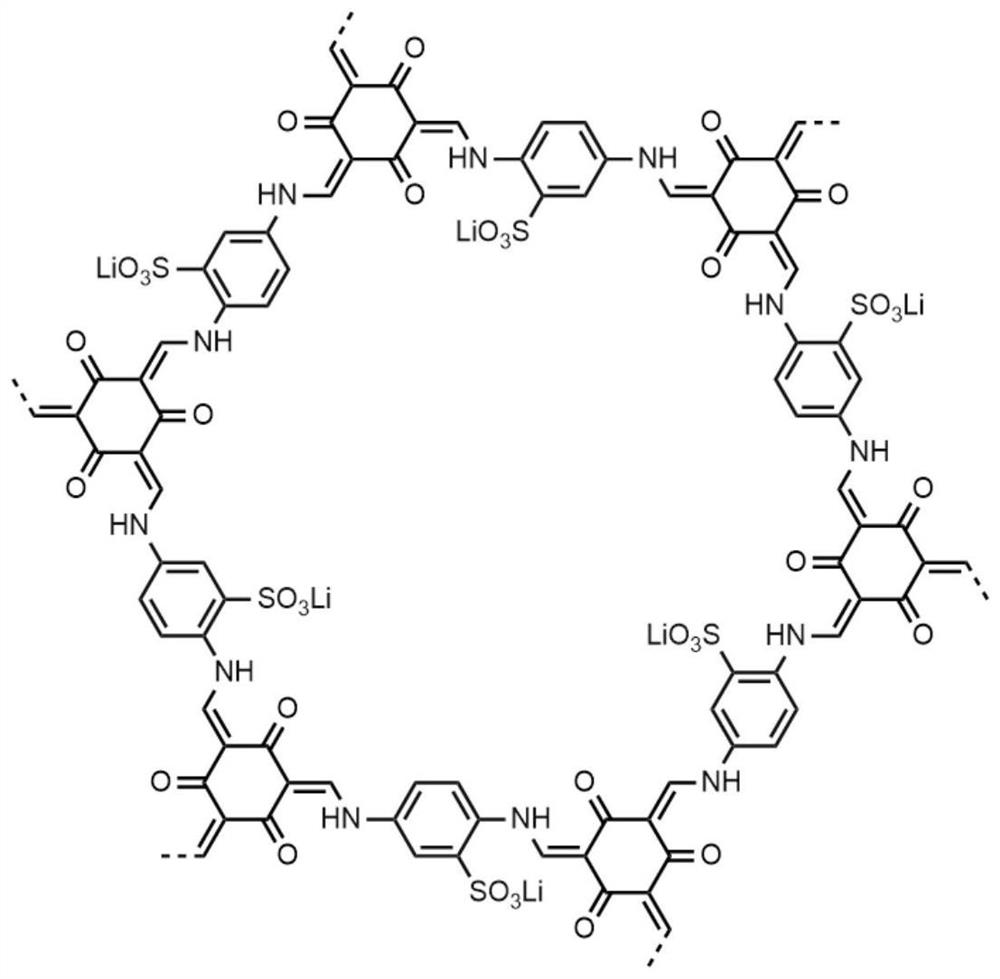

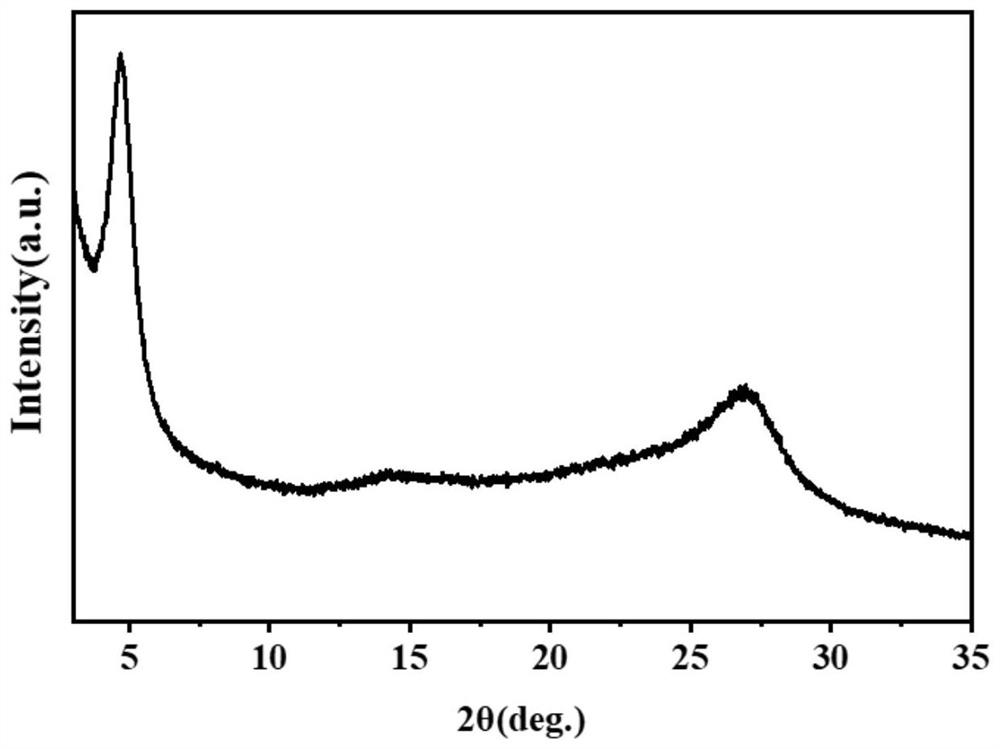

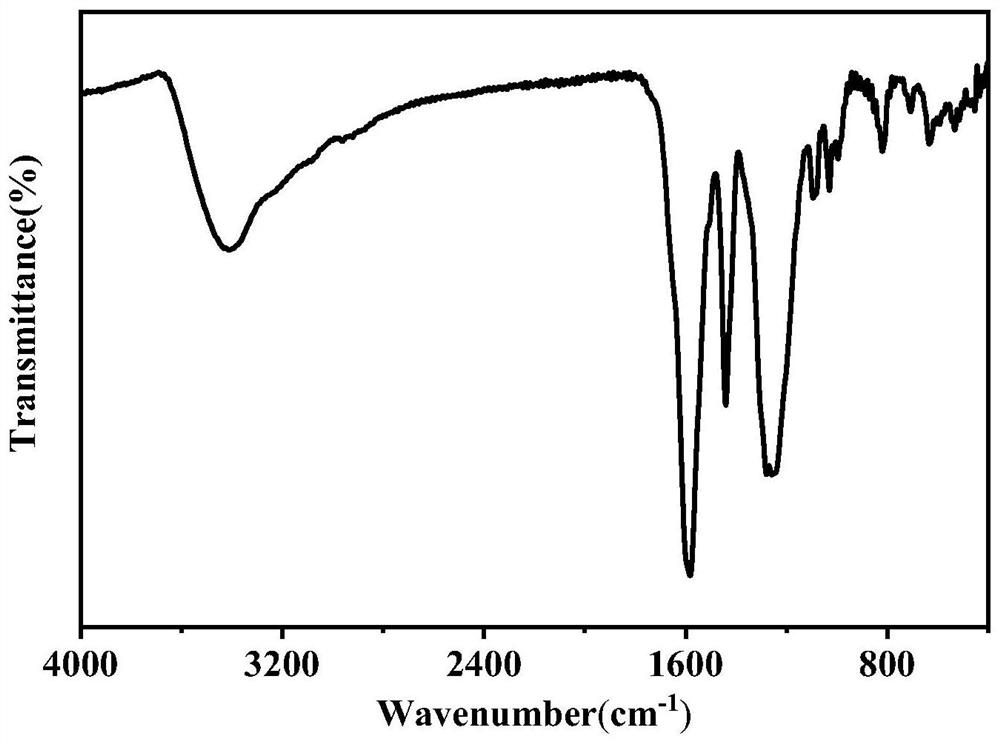

[0030] 1) Preparation of covalent organic framework: 63mg of 1,3,5-trialdehyde phloroglucinol (Tp), 84.7mg of 2,5-diaminobenzenesulfonic acid (Pa-SO 3 H), 0.6mL 1,4-dioxane, 2.4mL mesitylene, 0.6mL acetic acid solution with a concentration of 6mol / L, and sonicate for 10min. The reaction solution was frozen, evacuated, and melted with liquid nitrogen, and the operation was repeated three times. The reaction tube was placed in an oil bath and reacted at 120°C for 72h. After the reaction was completed, the solid product was collected by suction filtration, and washed three times with dimethylacetamide, deionized water, and acetone in sequence. After washing, the collected solid product was placed in a vacuum oven and dried at 120 °C for 12 h to obtain the covalent organic framework material TpPa-SO 3 H.

[0031] 2) Preparation of lithiated covalent ...

Embodiment 2

[0035] Example 2: Preparation of lithiated covalent organic framework composite polymer electrolyte, the steps are as follows:

[0036] 1) Preparation of covalent organic framework: 63mg of 1,3,5-trialdehyde phloroglucinol (Tp), 84.7mg of 2,5-diaminobenzenesulfonic acid (Pa-SO 3 H), 0.6mL 1,4-dioxane, 2.4mL mesitylene, 0.6mL acetic acid solution with a concentration of 6mol / L, and sonicate for 10min. The reaction solution was frozen, evacuated, and melted with liquid nitrogen, and the operation was repeated three times. The reaction tube was placed in an oil bath and reacted at 120°C for 72h. After the reaction was completed, the solid product was collected by suction filtration, and washed three times with dimethylacetamide, deionized water, and acetone in sequence. After washing, the collected solid product was placed in a vacuum oven and dried at 120 °C for 12 h to obtain the covalent organic framework material TpPa-SO 3 H.

[0037] 2) Preparation of lithiated covalent ...

Embodiment 3

[0040] Example 3: Preparation of lithiated covalent organic framework composite polymer electrolyte, the steps are as follows:

[0041] 1) Preparation of covalent organic framework: 63 mg of 1,3,5-trialdehyde phloroglucinol (Tp), 120.7 mg of 2,5-diamino-1,4-benzenediol were sequentially loaded into a Pyrex tube Sulfonic acid (Pa-Double-SO 3 H), 0.6mL 1,4-dioxane, 2.4mL mesitylene, 0.6mL acetic acid solution with a concentration of 6mol / L, and sonicate for 10min. The reaction solution was frozen, evacuated, and melted with liquid nitrogen, and the operation was repeated three times. The reaction tube was placed in an oil bath and reacted at 120°C for 72h. After the reaction was completed, the solid product was collected by suction filtration, and washed three times with dimethylacetamide, deionized water, and acetone in sequence. After washing, the collected solid product was placed in a vacuum oven and dried at 120°C for 12 hours to obtain the covalent organic framework mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Li-ion conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com