Composite positive electrode active material and lithium ion secondary battery

A positive electrode active material and technology for active materials, which are applied in the field of composite positive electrode active materials and lithium ion secondary batteries, can solve the problems of poor cycle performance of lithium ion secondary batteries, limited charging cut-off voltage of lithium ion secondary batteries, and the like, and achieve excellent Cycling performance and thermal stability performance, high energy density, effect of preventing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

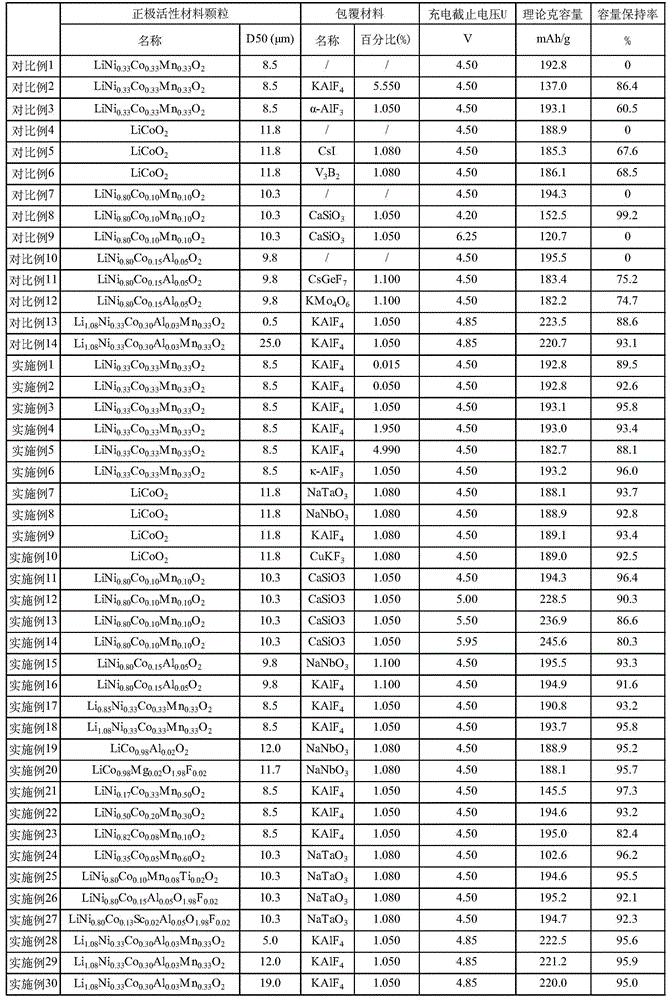

Examples

Embodiment 1

[0093] Prepare lithium ion secondary battery according to the method for comparative example 2, just in the preparation of the positive plate of lithium ion secondary battery (i.e. in step (1)):

[0094] KALF 4 The mass of is 0.015% of the mass of the composite cathode active material.

Embodiment 2

[0096] Prepare lithium ion secondary battery according to the method for comparative example 2, just in the preparation of the positive plate of lithium ion secondary battery (i.e. in step (1)):

[0097] KALF 4 The mass is 0.05% of the mass of the composite cathode active material.

Embodiment 3

[0099] Prepare lithium ion secondary battery according to the method for comparative example 2, just in the preparation of the positive plate of lithium ion secondary battery (i.e. in step (1)):

[0100] KALF 4 The mass of is 1.05% of the mass of the composite cathode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com